For a bunch of supposedly clever folks we sure do dumb things. One of the big ideas of the past couple of decades or so is to keep the heat out during cooling and keep the heat in during heating. The better we are at this the less energy we need to use to condition the interior. Apparently this concept has not caught on. How else do we explain modern construction that uses steel, concrete, aluminum and glass the way we do? For those who somehow missed high school physics, steel, concrete, aluminum and glass are all thermally conductive materials. Except for concrete, we make frying pans out of all of them.

If an alien from another planet1 looked at our construction practices he would conclude that we have too much heat in buildings and we want to reject that heat to the outside.2 We expose our concrete slab edges and our concrete frames. We build our structures like heat exchangers with protruding fins that transfer every last available BTU across them—like huge concrete “Harleys” with air-cooled structural frames (Photograph 1, Photograph 2, Photograph 3).

Photograph 1: "Harley Davidson" Architecture—The projecting concrete slabs transfer heat across the enclosure.

Photograph 2: Architectural Statement—Apparently, the projecting slab is visually appealing (who knew?). It catches rain and transfers heat efficiently while wasting floor area (square footage).

Photograph 3: Exposed Frame—The bad news is that we have built lots of these. The good news is that they are easy to fix by recladding them with exterior insulation.

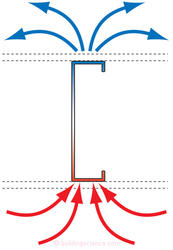

This logic (actually “illogic”) starts with the field of the wall. Steel studs are designed to provide the maximum possible conductive energy transfer across a wall using the minimum amount of material—a thin web with cleverly designed heat transfer fins (flanges) on both sides to efficiently absorb heat on one side and reject it on the other (Figure 1). It gets even worse when steel studs are used with a steel frame (Photograph 4). It is pointless to insulate the cavity to fight this efficiency of heat transfer. Of course if it is pointless, we do it. The lunacy has progressed to the point where we are using higher and higher thermal resistance cavity insulations like expensive spray foams. Why waste money on cheap insulation when we can waste even more on expensive insulation?

Figure 1: Efficient Heat Transfer—Steel studs are designed to provide the maximum possible conductive energy transfer across a wall using the minimum amount of material—a thin web with cleverly designed heat transfer fins (flanges) on both sides to efficiently absorb heat on one side and reject it on the other.

Photograph 4: Conductive Heaven—Not much to say here except “what were you possibly thinking?” It is a waste to insulate the cavities. Exterior insulation is the only rational option here.

The only solution is to insulate on the outside of the steel studs, which is easy, elegant, effective and efficient. Leave the cavity empty—put the insulation on the outside (Photograph 5). Done. Except when we actually do this, we don’t get the credit for it we deserve. We actually get penalized code wise and cost wise. Put an R-19 batt in a steel stud wall and you are lucky to get R-5 to R-6 in the real world. That’s equal thermal resistance wise to about 1 inch of rigid insulation installed on the outside of the steel studs. With an R-19 batt you meet the “nominal” code requirement. Know what “nominal” means? It means “in name only.” It is not the true performance. In a perversion of thermodynamics, most codes require you to install 4 inches of rigid insulation on the outside of the steel studs—a “real” R-20—to meet “equivalence” to the code stipulated “nominal” R-19.

Photograph 5: Exterior Insulation—The pink is the exterior insulation. The blue is the rain control layer (drainage plane) and the air control layer (air barrier) and the vapor control layer. The brown is the brick cladding.

If life was fair, 1 inch of rigid insulation on the outside of a steel stud wall assembly would be equal to installing R-19 in the cavity. It is equal in the real world, but not in the code world.3

The point here is that you are throwing away 75 percent of your thermal resistance with these thermal bridges—and that is only in the field of the wall. It gets much worse elsewhere, as we will see. Other thermal bridges reduce overall R-value even more.

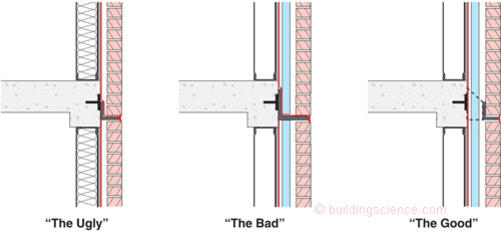

Okay, the field of the wall is easy—exterior insulation. Now it gets ugly. How do you handle the frame? How about running the insulation past the frame as with the exterior insulation on the steel studs in the infill wall? Not so fast. How are you going to support the cladding with this exterior insulation between it and the structure? That masonry veneer that architects love and client’s want is typically supported on a relieving angle welded to plates cast into the concrete slab edge (Figure 2). Or even more thermally conductive, the relieving angle is attached directly to a steel frame.

Figure 2: "Clint Eastwood" Thermodynamics—“The Good” uses offsets and exterior insulation. “The Bad” only uses exterior insulation. “The Ugly” uses neither.

Running the exterior insulation over the upturned angle doesn’t get you much because the two dimensional heat transfer gets you bad (see heat rejection efficiency of steel studs earlier). You spend a lot more money on the steel angle. It now has to be wide enough to accommodate the thickness of the exterior insulation and thick enough to handle the moment loading.4 The thicker angle transfers the heat even faster, so you actually loose more than you gain. So if we spend lots of money and get little in return, at least we are consistent.

We can fix this by standing the steel angle off the face of the frame with “off-sets." Steel “C-sections,” tubes or knife-edges are attached intermittently to the structural frame to hold the steel angle away from the frame, allowing exterior insulation to run past the steel angle between it and the frame (Photograph 6). Now, you can use a small and standard-sized steel angle because the stand-offs do all of the work. They handle that “moment” thing that worries structural engineers. This approach has the added advantage of better accommodating dimensional variations in the slab edge and allows for better rainwater control (“drainage plane”) details.

Photograph 6a: Offset Relieving Angle—The angle iron support for the brick veneer is held away from the structural frame allowing exterior insulation to run by.

Photograph 6b: Offset Relieving Angle—The angle iron support for the brick veneer is held away from the structural frame allowing exterior insulation to run by.

Okay, so that wasn’t so ugly. You want ugly, I’ll give you ugly: balconies. The typical balcony is a portion of the structural slab cantilevered past the structural frame projecting outward into the wild blue yonder —the ultimate thermal bridge (Photograph 7). The easy answer to this problem is getting rid of balconies. Unfortunately, as with most really bad ideas, they have this illogical appeal to the reptilian part of our brain.5 Why build them? They never get used. Do you ever see people on them aside from smokers? But I digress. We will have balconies despite all logic to the contrary.

Photograph 7: The Ultimate Thermal Bridge—A balcony is an efficient concrete-to-air heat exchanger that transfer every last available BTU across the structure.

Consider “off-set” point supports rather than cantilevering the slab. This works well with an articulated façade (Photograph 8 and Photograph 9). The balcony can be a precast unit that is gapped from the wall allowing exterior insulation to run past the balcony between the balcony and the structural frame of the building.

Photograph 8: Balcony Offset Point Supports—Precast balcony supported intermittently to break thermal bridge.

Photograph 9: Mind the Gap—Close-up of precast balcony supported intermittently. Note the gap between the balcony and the structure allowing exterior insulation to run by.

What if you don’t want an articulated façade? Use the “off-set” point supports described previously. But, now hang the balcony precast units with threaded rods tied back to the columns of the structural frame (Photograph 10). Neat, eh?

Photograph 10: Hang in There—Offset point supports combined with tie rods.

How about a stand-alone supporting structure (Photograph 11)? Or half a stand-alone tied back to the structure at the top and resting at grade on it’s own pier (that way there is not thermal bridge at the foundation)? Finally, a really impressive innovation from our structural engineering colleagues—stainless steel rods welded to reinforcing bars cast into the structural slab. The rods pass through a foam block that acts as a thermal break. The rods are staggered up and down to handle both compression and tension loads (Photograph 12).

Photograph 11: Stand-Alone Balcony—Balconies have their own structural frame and foundation.

Photograph 12: Structural Innovation—Thermal break at slab-balcony connection. Stainless steel rods are welded to reinforcing bars cast into the structural slab. The rods pass through a foam block that acts as a thermal break. The rods are staggered up and down to handle both compression and tension loads.

You can take this approach even farther with projecting structural members.

Who says we have to live with those thermal bridges? You want to get serious about energy efficiency? Get serious about thermal bridges. That means exterior insulation on steel studs and structural frames, off-set relieving angles for brick veneers and some serious structural-thermal thinking for balconies and projecting structural members. We mechanical engineers are going to have to get to know those structural engineers better. And then we both have to have a chat with the architect. Some interesting times are coming . . .

Footnotes:

Or an architect from another country—pretty much the same thing.

This “line” of logic (or “rant”) has been shamelessly stolen from the handsome and dashing John Straube, Professor of Civil Engineering, University of Waterloo—a pretty good University as University’s go—almost as good as the University of Toronto, my alma mater.

The only folks who do this even close to correctly are ANSI/ASHRAE/IESNA 90.1 members. Good job folks. No one in the code world seems to care, but you did the rest of us proud on this one.

Äsk a structural engineer about “moments”—they will love taking to you about them—really—no one interesting ever talks to them; it will make their day.

See also skylights and fireplaces in bedrooms. Skylights are holes in roofs that leak and condense water. I have yet to see one that works reliably. I shouldn’t complain about skylights though. I make lots of money fixing them, and they helped put my kids through college. Consider using things called dormers and monitors. And, don’t get me started about fireplaces in bedrooms. How romantic. You use them once and then they are nothing more than an ornament. You want romance? Get flowers and Viagra. Both are much less trouble than a fireplace and much more reliable. Flowers and Viagra don’t backdraft, don’t need combustion air and make-up air and don’t need carbon monoxide alarms to keep you from dying.