High performance precast concrete enclosure walls stand apart from most "rainscreen" walls in several key respects: how they control rain penetration, how they provide airtightness, and their sequence of construction. This guide reviews the requirements for high performance enclosures as they apply to precast concrete, with special emphasis on the control of rainwater penetration.

Introduction

Precast concrete has been used successfully to provide durable building enclosures for many decades. As requirements for thermal performance, air leakage and rain penetration control increase in modern buildings, designers are often considering precast concrete to provide a low maintenance, durable, long life solution. Although the exceptional durability of concrete is well understood and has increased over the last 50 years, rain control theory has advanced and there have been radical changes in the expectations for thermal and airflow performance.

Precast concrete enclosure walls stand apart from most "rainscreen" walls in several key respects: how they control rain penetration, how they provide airtightness, and their sequence of construction.

This paper reviews the requirements for high performance enclosures as they apply to precast concrete, with special emphasis on the control of rainwater penetration.

Building Enclosure Requirements

The building enclosure is defined as the physical component of a building that separates the interior environment from the exterior environment: it is an environmental separator. In practice, the building enclosure has to provide the “skin” to the building, i.e., not just the environmental separation but also the visible façade. Unlike the superstructure or the service systems of buildings, the enclosure is always visible, and therefore of critical importance to owners, occupants, and the public. The appearance and operation of the enclosure has a major influence on the interior environment and on factors such as comfort, energy efficiency, durability, and occupant productivity, satisfaction and health.

Figure 1: Attention to detail will ensure precast concrete wall panels provide high-performance enclosures.

In general, the physical function of environmental separation can be further grouped into three useful sub-categories as follows:

- Support, i.e., to support, resist, transfer and otherwise accommodate all structural loading imposed by the interior and exterior environments, by the enclosure, and by the building itself. The enclosure, or portions of it, can sometimes be an integral part of the building superstructure either by design or in actual performance.

- Control, i.e., to control, block, regulate and/or moderate all the loadings due to the separation of the interior and exterior environments. This largely means the flow of mass (rain, air, water vapor, pollutants, etc.) and energy (heat, sound, fire, light, etc.).

- Finish, i.e., to finish the surfaces at the interface of the enclosure with the interior and exterior environments. Each of the two interfaces must meet the relevant visual, aesthetic, durability and other performance requirements.

All practical enclosures must satisfy support, control, and finish functions, however, only the support and control functions are needed everywhere. Control and support functions must continue across every penetration, every interface and every assembly. The lack of this continuity is the cause of the vast majority of enclosure performance problems. The need for finish varies - it is unlikely to find an enclosure that requires a finish on the interior and exterior everywhere.

The support function is of primary importance. Without structural integrity, the remaining functions are of no use. The industry has reached a high level of understanding and accomplishment in this area.

For physical performance, the most common required enclosure control functions include resistance to: rain penetration, air flow, heat transfer, condensation, fire & smoke propagation, sound and light transmission (including view, solar heat, and daylight), insect infestation and particulate penetration, and human access. As these functions are required everywhere, continuity of these control functions, especially at penetrations, connections and interfaces between materials, is critical to a successful enclosure. The most important control function with respect to durability is rain control followed by airflow control, thermal control, and vapour control. The level of fire and sound control required varies with code requirements and owner requirements.

Unlike the control and support functions, which rely on continuity to achieve performance, the finish function is optional, and may not be needed in some areas, such as above suspended ceilings or in service or industrial spaces where the finish is often deemed unimportant. Exterior finish components are often termed “cladding”, but the term is imprecise, since cladding systems and materials often include some control functions (such as UV control, solar control, impact resistance, etc) while also serving their finish function.

As the most important control function, the control of rain penetration deserves special attention in all designs. This document focuses on the rain control of wall systems in general, and precast concrete walls in particular.

The Ontario Association of Architects commissioned the Rain Penetration Control Practice Guide (Straube 2005) in response to a rise in insurance claims with certain types of claddings. The guide clearly indicated that some types of enclosure systems do not need to be drained (e.g., glass, precast, low-slope roofs), although it has often been misinterpreted to mean all walls must be drained or even all walls must be “rain screens”. It does recommend the use of drained window openings, and the use of drained, two-stage joints. To supplement the guide, and avoid misunderstanding, a short review of rain control principles is provided next.

Rain Control Principles

There are three recognized design strategies to control rain penetration within and through the enclosure (Straube & Burnett 1999, CMHC 1999):

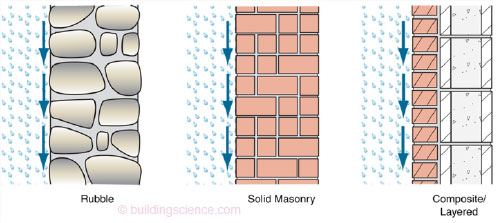

Storage: Mass or storage is the oldest strategy. Like drained systems, this approach assumes water will penetrate past the outer surface of the enclosure. It requires the use of an assembly of materials with enough moisture storage capacity and moisture tolerance to absorb all rainwater that is not drained from the outer surface. In a functional mass / storage wall, this moisture is eventually removed by evaporative drying from both the inside and outside before it reaches the inner surface of the wall as a liquid. Although enclosures employing this strategy might be best termed "moisture storage" systems, "mass" is often used because a large quantity of material is required to provide sufficient storage. The maximum quantity of rain that can be controlled is limited by the storage capacity available relative to drying conditions. Some examples of mass systems include adobe walls, thatched roofs, solid multi-wythe brick masonry, and single-wythe block masonry that is still employed for some modern buildings.

Figure 2: Mass (or storage) enclosure wall assemblies

Drained enclosures assume some rain water will penetrate the outer surface (hence the cladding “screens” the rain) and therefore the assembly must be designed to remove this water by providing drainage (comprised of a capillary breaking drainage plane, a drainage gap, flashing, and weep hole/drain). Many cladding systems, such as brick veneer and stucco, leak, as do the joints between other cladding types, such as shakes, terra-cotta, small metal panels, or natural stone. For these cladding types drainage is a practical and successful system of rain penetration control.

Figure 3: "Screened" and Drained enclosure walls

The term “rain screen” is applied to some drained systems, but the term is imprecise, as it means different things to different people. Drained walls may also be vented (a single, or single line of openings in the cladding connected to the exterior), ventilated (at least two openings through the cladding usually distributed between the top and bottom of the cavity), or even pressure-moderated (the air pressure in vented & ventilated walls tends to follow the exterior wind pressure, thereby “moderating the pressure”). Rain screen is applied loosely to all three different types of drained walls.

As drained systems can accommodate a range of claddings and backup systems, this approach to rain control has justifiably received a lot of attention from researchers and practitioners. However, drained systems are not always appropriate or the best strategy if good rain penetration control is desired. Existing multi-wythe solid masonry walls, glazing panels, and large-format precast panels are three common wall components that perform better if a strategy other than drainage is used.

Figure 4: Small-format, handset precast iinstalled as drained system

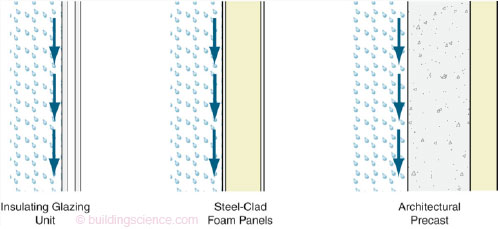

Perfect Barrier systems stop all water penetration at a single plane. Such perfect control required the advent of modern materials. Because it is difficult to build and maintain a perfect barrier with many materials, it is common to recommend the use of drained walls. However, some systems, usually factory built, provide wall elements that are practical perfect barriers. For example, architectural precast concrete can be considered watertight, as can glazing, and roof membranes (See Figure 5). The joints between perfect barrier elements should almost always be drained joints in the form of two-stage sealant joints or similar.

Perfect barriers may be face-sealed – where the perfect barrier is at the exterior face – or concealed barrier, where the barrier is protected behind other materials. Concealed barrier systems, such as Protected Membrane Roofs (PMR), have a long record of good performance. Others, such as stucco and adhered veneers applied directly over building paper have shown disastrously poor performance in many applications. The difference in experience is directly related to the likelihood of a perfectly waterproof barrier being achieved in construction and maintained over the desired lifespan. EIFS (synthetic stucco) can perform as a perfect barrier but experience has shown that rain leakage at the joints can be trapped within the system and this has caused thousands of failures. Current practise for EIFS is to use two-stage drained joints, and fully-drained systems are now widely available.

Figure 5: Perfect barrier enclosure walls

Joints

Joints are classified in the same manner as enclosure elements (Figure 6), although the joint and the enclosure element often use different approaches. For example, walls which use mass and perfect barrier elements often use drained joints to form a complete system.

Face-sealed sealant joints (e.g. a single line of exposed sealant) have a poor record of performance and cannot be recommended for controlling rain entry. Even exposed gaskets, often used to create the joint between insulated glazing units and the window frame, tend to shrink and crack over time. When these seals fail, significant water penetration occurs [Lacasse & Miyauchi 1997].

Figure 6: Three different rain control strategies at joints. Two-Stage drained joints are the recommended approach.

Perhaps the most common rainwater control failure occurs at window penetrations [e.g. Finn 1995]. Regardless of which rain penetration control strategy is used, window and door penetrations through enclosure walls should be drained. . .

Download complete document here.