As my friend Mac Pierce likes to point out: you could get a blindfolded drunk epileptic to cross Niagara Falls on a high wire without a net, but it wouldn’t be a good idea. There are some wall assemblies that are like that. One in particular irritates me. It has lead to a great deal of grief. It has problems that can easily be avoided. But simple analysis shows it works, and that is the rub. The simple analysis shows that it works, but the real world shows that it does not.1

It gets better. More complicated analysis shows that it sometimes works, and truth be told, the real world shows that it also sometimes works. No moisture and exceptional workmanship can make it work. What are the odds? Clint Eastwood thermodynamics again: do you feel lucky punk? Well, do you?

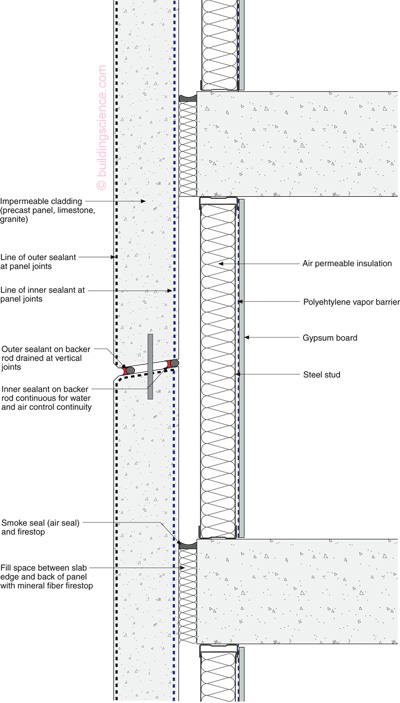

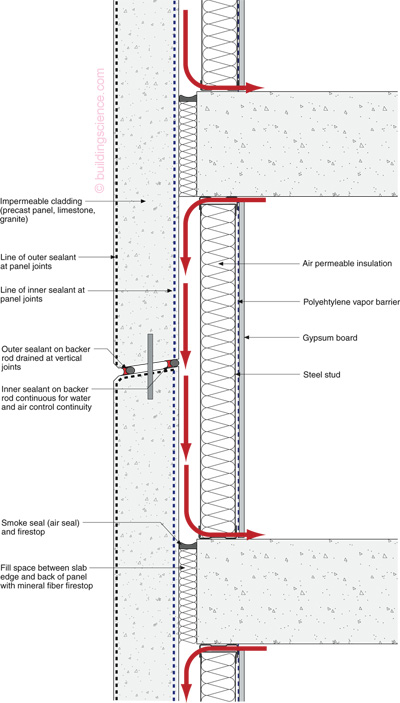

So what does this wall look like? I am not sure what to call it. It has a face-sealed cladding (“perfect barrier”) that is impermeable to water vapor. It is insulated on the interior with air permeable insulation usually held in place between steel studs or impaled on pins protruding from the back of the cladding and covered by a vapor barrier (Figure 1). Let’s call it a “Tom Cruise Wall.”2

Figure 1: “Tom Cruise Wall”–Face-sealed cladding (“perfect barrier”) that is impermeable to water vapor. It is insulated on the interior with air permeable insulation usually held in place between steel studs or impaled on pins protruding from the back of the cladding and covered by a vapor barrier.

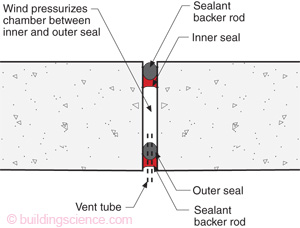

The cladding is often precast concrete or granite or marble or limestone (Photographs 1 and 2). Yes, it’s true. Caulked 2.5 in. (64 mm) Indiana limestone is the same as 5 in. (127 mm) precast panels. The joints in the cladding are sealed with some type of sealant. The more recent variations use a two-stage joint (yeah, baby!). The two-stage joint is a good thing; perhaps the only good thing in the entire mess. In these types of assemblies the rain control is a "perfect barrier” that works for the panels, but not at the joints and windows, therefore, two-stage drained joints are used at these locations.

Photograph 1: Face-Sealed Panels–High risk in cold climates if air permeable insulation is used.

Photograph 2: Back Side of Panel–First condensing surface if interior air gets access to surface.

The insulation is typically a fiberglass batt “smushed”3 between steel studs. Sometimes, it is rockwool or mineral wool pinned to the interior of the exterior cladding. The fiberglass batt sometimes comes with a foil facing–the “vapor barrier.” More often the whole kit and kaboodle4 is covered with sheet polyethylene that may, or may not, be called an “air-vapor barrier.” Yuck.

So what is the problem? Well, the cladding is easy to make almost perfectly airtight and the interior lining is almost impossible to make airtight. That’s it? Really? That simple? Yup. You’re kidding. Everyone knows you can’t seal plastic sheets on the inside of wall assemblies and make them airtight. Apparently, not everyone. Just folks who build them. Not folks who design the damn things or write specifications. And, apparently, not folks who do many of the calculations. And, just to be clear, this a problem for cold climates defined here as north of the Mason-Dixon Line.5

Let's work backwards. A straight vapor diffusion analysis shows that all you have to do is add a vapor barrier on the inside of the assembly in cold climates and everything works. Never mind that the calculation does not reflect the real world. Hey, the boss wanted a calculation, and here it is. Simple. The arithmetic is correct. Too bad the answer does not apply. If there is no air movement across the assembly, the calculation works. How realistic is that? In theory it works, but then again so does Communism.6

The saving grace for many of these assemblies is that the buildings are usually overventilated and not humidified, and under-occupied so that interior moisture levels in the winter tend to be low, much lower, than calculations give credit. But, every now and then, buildings are full of happy productive folks. How does occupancy affect things? People are nothing more than evaporatively cooled unvented combustion appliances: power humidifiers. More people, the more humidification and moisture levels can easily go above 15% to 20%, and then presto, up on the high wire you go.

Or even worse, you can get the real thing: a building that is humidified; once you get above 30% you are dead. Try this in Minneapolis or Buffalo, N.Y., in a humidified building or a fully occupied building, and it is all over. So what are the consequences? Condensation, corrosion, mold and odors.

The actual mechanism is pretty easy to conceptualize: convective looping of interior air between the interior and the interstitial cavity existing between the back of the cladding and the interior gypsum board lining (Figure 2). Warm and moist interior air migrates into the interstitial cavity through gaps in the interior gypsum board and through gaps in the impossible to perfectly seal plastic or foil interior “vapor barrier.” This warm and moist interior air passes through the air permeable insulation and contacts the backside of the cladding. The cladding is, for all practical purposes, uninsulated and, therefore, at close to exterior temperature. As a simple first order approximation7 whenever the exterior temperature of the interior air, bad things happen (Photographs 3 and 4).

Figure 2: Failure Mode–Convective looping of interior air between the interior and the interstitial cavity existing between the back of the cladding and the interior gypsum board lining leading to condensation, corrosion, mold, odors and generally bad things.

Photograph 3: Weeping Building–Face-sealed building where condensation is leaking out cladding joints.

Photograph 4: Interior of Weeping Building–Typical steel studs, fiberglass batts, polyethylene vapor barrier and faith-based air sealing. No chance. This building was humidified. It “cried” as a result.

Note the bad things only happen if air from the inside gets to the back of the cladding and only if this air has moisture in it. The hard part to control is the airflow part; the easier part is to control the moisture in the air part.

The airflow control part means caulking and sealing and caulking and sealing and then praying a great deal. We call this "faith-based air leakage control." Good luck. Buying lottery tickets is probably a better option. The Leafs winning the Stanley Cup is certainly a better option. Precast makes for beautiful building (Photograph 5). But will it work? Ah, the high risk versus low risk question?

Photograph 5: Federal Reserve Building in Minnesota–Beautiful. But will it work?

The moisture in the air part can be controlled by not humidifying and by ventilating buildings in cold climates to keep interior relative humidities during the coldest part of the winter very low. How low? Uncomfortably low. The colder the climate, the lower the interior humidity necessary. How do you figure this out? Well, when the bad things stop happening you know what that humidity is. Aw, come on. Can’t you calculate it? Not really. Have you any idea how complicated a problem it actually is to calculate if you wanted to do it correctly? It is a three-dimensional fluid flow problem with a whole bunch of heat transfer thrown in to make things interesting. And the hard part is that you have to guess at the boundary conditions such as what the actual leakage pathways are and what the actual air pressure differences are.8

There are only a few guys I would trust with this, and even then, it is nice to know what the answer is beforehand.

So, what do I recommend? Experience tells us that in most cases "that it can't be worse than this" and "it can't be better than this." You bound the problem, and use judgement (a real good guess based on experience) as to where things lie between the best and the worst case. Here is where the calculations become useful. You make sure they always fall between the two boundary conditions. The worst case is that first order approximation I talked about earlier. Yes, but in the worst case what exterior temperature do you pick? Ah, the judgment based on experience part kicks in. Take the average exterior temperature of the coldest month. Very conservative. You want to be even more conservative? You want to be “Tea Party” conservative? Take the average of the daily lows for the coldest month. The best case is no airflow at all. There you go. Easy after all.

But why even go through the brain damage at all? Why not make the problem go away completely by not letting air get to the backside of the cladding? Use a spray-applied air impermeable insulation on the backside of the cladding. Or use a precast concrete panel that is internally insulated. That and two-stage joints and life is good. The assembly works, and even better, you don’t have to do a calculation.

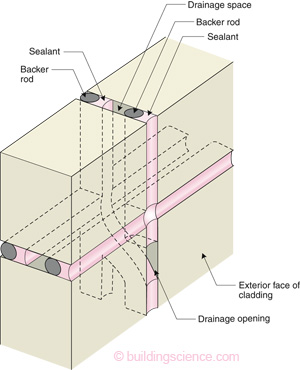

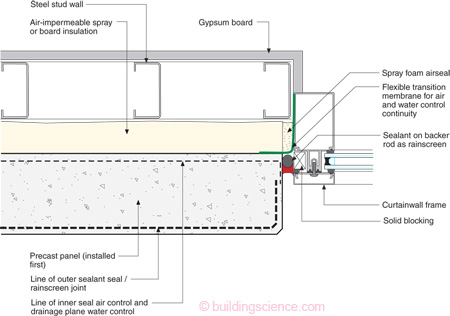

So what is a two-stage joint? Well, we talked about them in BSI-004: Drainage, Holes and Moderation. Figure 3 is from that discussion. An inner and outer seal provide drainage at joints. The outer seal is exposed to the elements and gets trashed by the UV and heat and water, but the assembly still works because of the interior protected seal. This interior seal is installed from the exterior for continuity reasons. Figures 4a and 4b show the vertical section through the joint in both 2-D and 3-D. Pretty clever, huh? The drainage to the exterior is being done with the outer seal sloped to the interior at drainage openings. I love stuff like this.

Figure 3: Two-Stage Joint—An inner and outer seal provide drainage at joints. The outer seal is exposed to the elements and gets trashed by the UV and heat and water but the assembly still works because of the interior protected seal. This interior seal is installed from the exterior for continuity reasons.

Figure 4a: Draining Joint (2-D)–Clever use of sealant to direct water that may enter joint cavity to the exterior.

Figure 4b: Draining Joint (3-D)–Need to draw it up three dimensionally in order to “get it.” Brilliant.

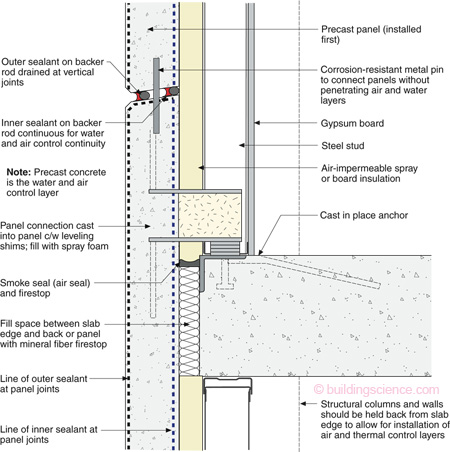

So what does a “low risk” wall look like when you use a face-sealed cladding (“perfect barrier”) that is impermeable to water vapor? Check out Figure 5. Note the air impermeable spray insulation or board insulation that is applied directly to the interior of the exterior cladding. The spray insulation should be spray polyurethane foam—the “high density” stuff—2 lb/ft3 (0.91 kg/m3) closed cell material when you are north of the Mason-Dixon Line. A big trick in making this work is pulling back the columns and beams at least 6 in. (152 mm) or so to allow continuous access to the back of the cladding. Trust me on this. The other big deal is to integrate the window into the assembly. Two-stage joints all around (Figure 6).

Figure 5: Low Risk Wall–Impermeable face-sealed cladding (“perfect barrier”) that is internally insulated with air impermeable insulation. Typically spray applied 2 lb/ft3 (0.91 kg/m3) polyurethane foam or rigid foam board directly adhered to the backside of the exterior cladding with all joints sealed.

Figure 6: Window-to-Wall Interface–Note the use of two-stage joints around

the perimeter of the window opening.

An even better approach is where you create a sandwich panel: a preinsulated precast panel (Figure 7). No fuss, no muss. About as low risk as you can get. Tom Cruise eat your heart out.

Figure 7: Sandwich Panel–Low risk preinsulated precast panel. Rigid insulation located between two layers of concrete that comprise the panel.

Footnotes:

Not always true; read the next paragraph. Literary license, some exaggeration is allowed.

Tom Cruise broke out in the fabulous movie “Risky Business” with a little bit of help from Bob Seger.

- How else would you describe the installation of fiberglass batts in steel studs? The words neat and clean or level and square with no wrinkles do not come to mind.

- Real warriors like those DEVGRU (Seal Team 6) with JSOC (Deuxieme Force operationnelle interarmees) with the CSOR carry around everything they need in a kitbag (dates back to the British) who gave us all the lads in Special Air Service (SAS), the granddaddy of the best of the best. Nicely done guys. The whole kit is what you take on deployment. “Boodle” is thought to mean a collection of things or estate. The “Ka” was added probably by some guy who makes things up because it sounds better, probably an early building science consultant.

- Surveyed between 1763 and 1767 by Charles Mason and Jeremiah Dixon in the resolution of a border dispute between British colonies in Colonial America (from Wikipedia). Today, it is more or less the border between Pennsylvania and Maryland. Historically, it became a big deal relating to the legality of slavery and, ultimately, the Civil War.

- This is a “Straubism.” I stole this line from my partner and friend John Straube. I steal only from the best.

- Don’t you love the way we old guys talk? This translates into “common sense tells you….”

- Simulations without real-world benchmarking are a huge unknown. You can get almost any answer you want. You have to be really good and really careful about your assumptions. It is not that it can’t be done; it is just that it is often easy to get it very wrong.