* Credit to architect Edward Mazria: I think he said this first, if he didn't say it first he sure says it well.

Many “green” buildings don’t save energy (see “MIS-LEED-ING” sidebar). Why? They have too much glass, they are over-ventilated, they are leaky to air, they are fraught with thermal bridges and they rely on gimmicks and fads rather than physics.

Basically, the current green and sustainability craze can be summed up as architects and engineers behaving badly. The good news is that most of this nonsense can be easily remedied when adults finally get involved. The bad news is that the failures are beginning to bubble to the surface and we are in danger of ruining the “green brand.”1

Before you can have a “green” building you need a building first. Presumably this building needs to be able to stand up, not be blown away in a hurricane, not fall down in an earthquake, not burn, not leak rainwater, not be moldy, not rot, not corrode and otherwise be able to meet applicable building codes such as having a basic provision for ventilation like that specified by Standard 62.1.

So what’s with all these “green” programs providing “points” for “durability” and “indoor air quality”? I mean it’s pretty pathetic if we have to reward architects and engineers when they provide details and specifications that should be basic to fundamental practice. If you design and install a controlled ventilation system that meets Standard 62 you get points. You get more points if you keep the rain out and design the building to dry if it gets wet. And you get still more points if the occupants are actually comfortable. Aren’t these code requirements? Shouldn’t these be “the standard of care”?

Have we architects and engineers sunk so low that we now get points if we meet basic building requirements that all buildings should meet in order to be called buildings?

Green programs waste a lot of time and money on stuff that is obvious and more time and money on stuff that is irrelevant or unimportant.

How about focusing on stuff that is important? It’s become “all about the points” and the important stuff gets ignored. Chasing “green points” doesn’t get you good buildings that are truly green. You can get a Leadership in Energy and Environmental Design (LEED) rating and not save any energy compared to traditional buildings. How can that possibly be green?

How To Be Green So, lets start with a basic requirement that we need a building that meets code and the standard of care. That would be a building that is structurally sound, is fire-safe, has a controlled ventilation system, does not leak rainwater and is comfortable. No points for this. This is what the minimum requirement for a building should be.

Now what’s next? That’s pretty easy. It’s energy. What are the two greatest challenges facing the Republic since the pesky British at Bunker Hill and Robert E. Lee leading the Confederate Army? Global warming and energy security. The key to both Global Warming and Energy Security is energy conservation. Architect Edward Mazria likes to say “architects control the global thermostat.” I think he is right.

Show me a building that meets code and the standard of care and saves energy and I will show you a green building. A “real” green building, not a social statement that saps money, time and resources from the real problems facing the planet.

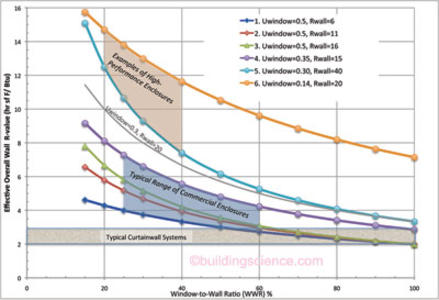

You want to save serious energy and serious money? Easy, use less glass. Windows and curtain walls are the most expensive component in a building and provide the worst energy performance. The more you use the more energy and money you burn. Limit the glazing area to approximately 30 percent—and use really good glass and frames (Figure 1).

Figure 1: Enclosure R-value versus Glazing Ratio Bottom line is use less glass and use good glass and frames. Chart is courtesy of John Straube (6). Bad glass ruins good walls. Rock beats scissors, paper beats rock… The impact of thermal bridging through commercial wall assemblies, and heat flow through window systems can be calculated with relatively good accuracy by calculating an area-weighted average of the R-values of the windows and opaque wall sections. The equation takes the form: Uoverall = (WWR *Uwindow + (1-WWR) * Uwall), where U = 1/R. The results of a number of scenarios are plotted in the chart below. Typical curtainwall systems have an R-value of only 2 or 3, with "high performance" systems (not shown) using highly insulated spandrel panels and best-in-class double glazing may achieve R-4. Only a few systems, such as the Kawneer 7550 series, can achieve R-values of 6 or more.

Curve 1 above is for standard U=0.50 thermally-broken aluminum punched windows with air-filled double-glazed insulated glazing units in a R-12 batt-filled steel-stud brick veneer wall system (R-6). The overall effective R-value of this wall is around 3-to-4 over the normal range of window-to-wall (WWR) ratios of 25 to 50%. Curve 2 shows that Increasing the R-value of the wall to R-11 by adding an inch of foam on the exterior, results in an increase of only R-0.5 to R-1.5 for the overall R-value for the same range of WWR. Curve 3 shows how significant an impact window performance can make if a good wall is provided. An externally insulated R-16 wall, when mated with poor windows produces a vertical enclosure with an R-value of only R-3 to R-6 for the normal range of window area. Curve 4 assumes a good quality window frame with top quality glazing (low-e, argon-filled): the result for the overall vertical enclosure is still only R-4 to R-7. These first four curves cover the performance of a wide range of commercial enclosures with a wide range of cladding types. The conclusion is that modern commercial vertical enclosures actually have an R-value that is rarely over 7, and more likely in the range of 3-to-5! Curves 5 and 6 provide an idea of the significant improvements that are possible. Using best-in-class thermally broken aluminum frames and high-performance glazing (U=0.30), Curve 5 shows that even with an R-40 wall, the overall R-value will be in the 7-to-12 range for WWR of less than 40% (the highest ratio recommended for high-performance buildings). Even though this is a low-level, it is still about significantly more than the alternative. The grey curve below Curve 5 shows the slight benefit gained by increasing wall R-value from 20-to-40, particularly at high glazing ratios. Curve 6 employs low-e, argon-filled triple-glazed units in an insulated fiberglass frame, to deliver a U-value of only 0.14. Even with a wall insulated to "just" R-20, such a combination can deliver an overall R-value of 12-14, two to three times more than typical commercial vertical enclosures. In all cases, it can be seen that high glazing ratios generate enclosure walls that are expensive to purchase with very high heat loss and heat gain. This high ratio should be avoided in both individual spaces, such as meeting rooms, as for the whole building on average. |

Then don’t over-ventilate. This idea of getting green points by increasing the rates above those specified by ASHRAE Standard 62 is just madness. Whatever happened to source control? If you don’t build stupid materials into the building, don’t do stupid things in the building and don’t connect the interior to exterior via the parking garage, 62 works very well.

Next, build an enclosure without big holes. Build tight, ventilate right. Tight is 2.0 l/s/m2@75Pa (1). Right is ASHRAE Standard 62. How complicated can that be? Except we don’t do it.

Moving on, don’t insulate steel stud cavities; insulate them on the outside. Most of the time all that you will need is R-10 of continuous exterior insulation (that’s between 1.5 and 2 inches of rigid insulation).

And don’t use supply or return plenums—use something called “ducts” to avoid air quality problems and to ensure air goes where you want it.

How Not To Be Green Once we get an enclosure, we can then condition it. Note to architects: before you can control air you must first enclose air. The enclosure comes first and is more important than all the systems within it. Mechanical engineers—all call themselves green—all claim to do green design but when push comes to shove few of them want to do the additional work necessary to design a mechanical system matched to a high performance enclosure—they want their money for nothing and their chicks for free. Of course not too many clients actually want to pay the engineer for the design—and if the money is spent it is often wasted because the enclosure is bad. You can’t make a building green by having the mechanical engineer try to compensate for stupid building enclosure design.

What’s “green” about under floor supply plenums? How do they save any energy? They sure as heck don’t contribute to indoor air quality – they make it worse. Do you want the breath air delivered in a ductless void under the floor than cannot be cleaned? You ever been in one? They are under everything— duh—so stuff collects in them. They have to be cleaned, but you can’t clean them because you can’t easily get at them and you can’t easily clean them even if you get at them because they are filled with services and so they are filthy. And they are expensive. The building has to be taller. That burns up resources and money. But it’s green. Says who? More money, more energy, more resources and more problems. What’s green about that?

You want to have some fun? Go ask the folks at the General Services Administration (GSA) about how they feel about under floor supply plenums. While you’re at it also ask them about computational fluid dynamics (CFD) and passive ventilation and San Francisco’s Federal Building. They won’t be able to say much because the ongoing employee litigation has them under a gag order. Go to Google and the Internet and enjoy. Or how about Seattle's new LEED city hall, which turned out to be a dog? Then we have Sir Norman Foster's London City Hall—supposed to be the greatest greenie public building ever. It just got rated an "E" on the efficiency on a scale that runs from A to F based on just released utility consumption. Apparently the lunacy is not limited to this side of the Atlantic.

Double façades? Green? What’s with that? I thought we killed that dumb idea after all the nonsense associated with “double envelope” houses in the 1970’s.2 It seems that really dumb ideas keep coming back every other generation—typically after the generation of adults that dealt with the dumb idea the first time around retires (Photograph 1 and Photograph 2).

Photograph 1: Hooker Chemical Company—The folks that brought us the Love Canal also brought us the first double façade building in the United States in the 1970’s.

Photograph 2: Mind the Gap—More Hooker Chemical Company building double façade. Not a heck of lot more needs to be said here. The population of a small village could live in this space.

Here is the general premise behind the double façade. The outer façade creates a buffer space between it and the inner façade tempering the environment the inner façade sees. So we have to build two walls—not one—an outer wall and an inner wall with a bunch of space in between. Seems to me that if you built the inner wall correctly you don’t need the outer wall—and vice versa. We call that a “duh” where I’m from. And then you get to use the space between them because there is no space between them—it is all inside—we call that rentable floor area where I’m from. Double façades are a low energy way to provide an all glass enclosure, but they always use more energy than a decent façade with less than 100 percent glass. Why ever go there?

Oh, I forgot about all the passive ventilation “magic” that happens between the two facades and the operable windows you can have between the inner façade and the “magic” space. All brought to you with the precision and predictability of computational fluid dynamics (CFD) and the stack effect. Emswiler (2) and Hutcheon (3) are rolling over in their graves and Shaw and Tamura (4) are none too pleased. I call on the ghosts of building science past to rise up and put a pox on all your houses.

I have got news for all you façadists—you can have operable windows in a single façade and you can get a lot more control and predictability with things called fans, ductwork and controls. Oh, by the way, you can get it at a lot less cost, using a lot less materials (i.e. “resource efficiency”) and using a lot less energy. But, but, fans use energy—it’s not natural to use fans. The other way, the “magic” way uses “natural” forces that are good because nature is good and man is inherently evil. Didn’t we have this argument over two hundred plus years ago with a dead French guy called Rousseau? If we taught architects more physics and less philosophy they wouldn’t fall for this garbage—and while I’m at it shame on you engineers for using bad physics to deceive gullible architects.

Green roofs? Grass and dirt are not energy efficient. Work with me here. Which saves more energy—2 inches of dirt or 2 inches of insulation? Which saves more energy—grass or a white colored membrane? Which is more expensive and does not save energy— grass and dirt or insulation and a white colored membrane? Which needs to be watered to keep the grass from dying and blowing away? But they are beautiful and look cool. And that apparently is more important than cost and energy savings. Okay, I can live with the beautiful and looking cool argument if that is in fact the argument—but don’t clutter it with half-truths such as heat island effects and water run-off. There are other ways to deal with each.

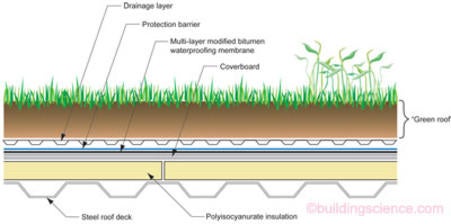

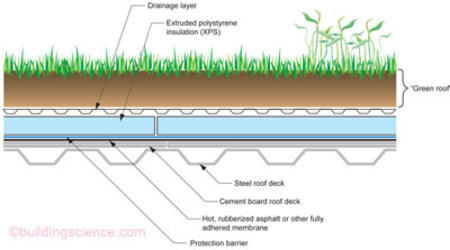

I know I will not win the argument on green roofs, so my advice is to at least build the green roofs correctly. In the “green world” folks sometimes get so pre-occupied with “green materials” that they forget that at the end of the day the assembly still has to work (Figure 2 and Figure 3).

Figure 2: Bad Green Roof—The insulation is under the membrane. This is bad. The insulation can collapse and loose support for the membrane. The membrane can tear and leak. The reason for this bad design choice is often a preoccupation with the "greenness" of the blowing agent of the rigid insulation. Successful green roofs have historically used extruded polystyrene (XPS). XPS can get wet and still perform. The blowing agent of XPS is arguably not the "greenest of the green." Uproven "green" blowing agents used with polyisocyanurate insulation seem attractive at first blush, but insulation assemblies need to be protected from water and hence the location under the membrane and the structural loading of the overbuild assembly needs to be taken into account.

Figure 3: Good Green Roof—The insulation is over the top of the membrane. This is good. This configuration has a multi-decade track record.

And enough with the awards before a building is built and the performance is verified.3 Award plaques should come with removable screws.4 Show me the utility bills. Compare the building to a building of similar size and similar occupancy in a similar climate. And if you don’t show any savings—shut up. You can’t be “green” if you don’t save any energy. Don’t talk to me about biological diversity, recycled materials, and natural ventilation until after you have saved the energy. Spare me the social engineering and the smaller is better and how we all have to share the planet and how we are all equal until you have saved the energy. Don’t talk to me about carbon off-sets until you have saved the energy. You need some carbon savings before you can trade any (the Kyoto protocol requires that the carbon credits be verified, i.e. a piece of paper saying we intended for there to be carbon reductions doesn’t do it). Save one and you can trade one. Don’t build an award winning energy pig and say you are green because you planted some trees in Zaire and brought clean water to a village. Those are all good things but they mean nothing to me because you still have a poor building.

Royal Building Scientist: Charles questions 'green' buildings Oct 12, 2008 Source: Copyright 2008, Press Association The Prince of Wales has criticised the "green building industry" for relying on eco-gadgets like wind turbines and solar panels to justify inefficient buildings. The Prince called on developers to use traditional methods and materials alongside the best in "eco-technology" to solve the problem of creating environmentally friendly properties instead of opting for "slick, highly marketed techno-fixes". His comments received a mixed welcome from Paul King, chief executive of the UK Green Building Council, who said they would provoke a healthy debate but risked undermining the efforts of the UK's emerging green building industry. In the foreword to a green supplement in the magazine House & Garden, the Prince wrote: "Why, I must ask, does being 'green' mean building with glass and steel and concrete and then adding wind turbines, solar panels, water heaters, sedum roofs, glass atria - all the paraphernalia of a new 'green building industry' - to offset buildings that are inefficient in the first place? "That many of these add-ons are mere gestures, at best, is now clear, as their impacts on home energy consumption can now be measured and usually offer scant justification for the radical nature of the design." Experts believe small-scale energy generation can help in the push for more renewable energy with businesses, communities, schools and homes playing their part by installing items like solar panels for heating, biomass boilers and combined heat and power supplies. In December last year, the Government outlined a multi-million pound Government scheme to fund schools to install renewable energy sources such as wood-burning boilers, wind turbines and solar panels to cut carbon emissions. Charles added: "We must act now, by using traditional methods and materials to work with nature rather than against her, while incorporating the best of contemporary eco-technology in an integrated and sympathetic manner." Speaking about the Prince's comments, Mr King said: "In a way he is right - there are examples of high-profile buildings being passed off as 'green', when the most important thing is to reduce environmental impacts through good design in the first place. "However, he risks undermining the efforts of UK's emerging 'green building industry', the vast majority of whom are designing an increasingly large number of fantastic buildings - not just environmentally sound, but excellent architecture in their own right." Typical Reaction from the ArchitectsAttack the messenger rather than fix the problem. Criticism of any kind is bad because "green" is good; don't criticize green because that would prevent people from adopting green. The interesting thing is that Prince Charles actually "gets it" but his rather astute observations are downplayed! —JWL |

References

(1) Lstiburek, J.W.; Understanding Air Barriers, ASHRAE Journal, July 2005.

(2) Emswiler, J.E.; The Neutral Zone in Ventilation, ASHVE Journal, Vol. 32, 1926.

(3) Hutcheon, N.B.; Fundamental Considerations in the Design of Exterior Walls for Buildings, Engineering Journal, Vol. 36, No. 1, pp. 687-698, June, 1953.

(4) Shaw, C.Y. and Tamura, G.T.; Studies on Exterior Wall Air Tightness and Air Infiltration of Tall Buildings, ASHRAE Transactions, Vol 82, 1976.

(5) Johnson, Brian; Energy Inefficient, North Carolina Lawyers Weekly, September 8, 2008.

(6) Straube, John; Can Highly Glazed Building Facades Be Green?, Building Science Insights, BSI-006, www.buildingscience.com, September, 2008.

Footnotes:

“Michael Zatz, manager of the commercial building program for Energy Star, an EPA program to promote energy-efficient products and practices . . . says Energy Star has a user-support line that gets calls from green-building owners and managers who are disappointed in their building’s energy performance.”(4).

What a weird decade—not only did we have double envelope houses but we also had leisure suits and the “Bionic Woman.” With double facades in vogue and the Bionic Woman* back on network TV can leisure suits be far behind?

* With the double facades, we can rebuild them, we have the technology, we can make them warmer, cooler, more comfortable, cheaper . . .

Larry Spielvogel was right about this – he got trashed when he had the audacity to question the claims of energy savings based on computer simulations, a.k.a. “Nintendo Engineering," as one Fellow to another – you done good big guy.

This idea is from the irrepressible Henry Gifford, New York City, NY. Yo, you talking to me?