The requirements in the code can be used for wood framed structures with temperature and humidity conditions typical of residential occupancy.

Three classes of vapor control are defined depending on the vapor permeance of the vapor control layer.

- Class I . 0.1 perms e.g. polyethylene sheet, sheet metal, or aluminum facing.

- Class II. 0.1 - 1.0 perms e.g., kraft faced fibreglass batts, and some vapor control paints.

- Class III. 1.0 - 10 perms e.g. latex or enamel paints.

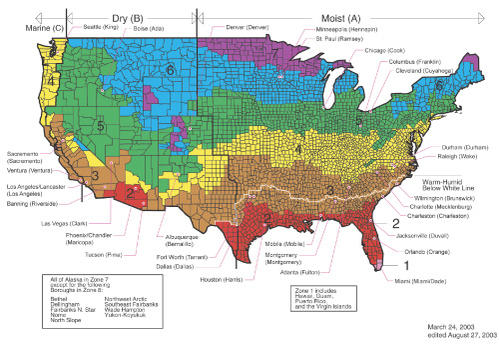

The level of vapor control required on the interior side of framed walls with typical fibrous cavity insulation (fibreglass, rockwool, or cellulose) is determined based on DOE climate zone of construction (see climate map).

No interior vapor control required on the interior side of framed walls in climate zones 1, 2, 3, 4a, or 4b.

In hot, humid climates, a Class I or II vapor control layer on the interior of the framing can, and often does, cause premature building enclosure failure due to inward moisture drive condensation (see RR-9302: Humidity Control in the Humid South). BSC recommends avoiding Class I or II vapor control layer on the interior in these zones, or any material that acts inadvertently like a Class I or II vapor control layer such as reflective foil insulations, vinyl wall coverings, glass mirrors and epoxy paints.

A Class I or Class II vapor control layer is required by the IRC on the interior side of framed walls in Zones 4c, 5, 6, 7, and 8, with the exceptions of basement walls, below grade portion of any wall, and wall construction that is not sensitive to moisture or freezing (e.g. concrete block wall). However, BSC recommends avoiding Class I vapor control layers in general in wall assemblies, except in special use occupancies in cold climates such as indoor pools and spas.

Below grade spaces such as basements are of particular concern with respect to Class I vapor control layers. Because the moisture drive in below grade walls is always to the interior, installing a high level of vapor control on the interior of the wall will cause moisture related durability issues by trapping moisture in the enclosure (see BSD-103: Understanding Basements). However, a Class I vapor control layer could be used in a below grade assembly under the following conditions: (a) no moisture-sensitive material is trapped between the concrete and the Class I vapor control layer, (b) this space is completely isolated from air communication with the interior, and (c) the Class I vapor control layer is protected from interior-sourced condensation. An example of this assembly would be foil-faced polyisocyanurate applied to the basement wall, with the gap between insulation and concrete isolated and air sealed from the interior.

A Class III vapor retarder can be used instead of a Class I or Class II in zones 4c, 5, 6, 7, or 8 where one of the criteria for the specific zone from the list below is met. These criteria may depend on whether the cladding is vented or whether insulating sheathing is used.

A class III vapor control layer may be used on the interior of framed walls in Zone 4c and higher, if the following criteria are met:

Zone 4c (e.g. Seattle or Portland)

- Vented cladding over OSB, plywood, fiberboard or exterior gypsum sheathing

- Insulated sheathing with an R value ≥ 2.5 on a 2x4 framed wall

- Insulated sheathing with an R-value ≥ 3.75 on a 2x6 framed wall.

Zone 5 (e.g. Boston)

- Vented cladding over OSB, plywood, fiberboard or exterior gypsum

- Insulated sheathing with an R value ≥ 5 (e.g. 1” XPS) on a 2x4 framed wall

- Insulated sheathing with an R-value ≥ 7.5 (e.g. 1.5” XPS) on a 2x6 framed wall.

Zone 6 (e.g. Minneapolis)

- Vented cladding over high permeance (>10 perm) sheathings of fiberboard and exterior gypsum

- Insulated sheathing with an R value ≥ 7.5 (e.g. 1.5” XPS) on a 2x4 framed wall

- Insulated sheathing with an R-value ≥ 11.25 (e.g. 2” PIC) on a 2x6 framed wall.

Zones 7 and 8 (e.g. International Falls or Alaska)

- Insulated sheathing with an R value ≥ 10 (e.g. 2” XPS) on a 2x4 framed wall

- Insulated sheathing with an R-value ≥ 15 (e.g. 3” XPS) on a 2x6 framed wall.

Vented claddings are described in Section R601.3.3 of the IRC and include vinyl or horizontal aluminum siding, brick veneers with clear airspaces, and other approved vented claddings.

Insulated sheathing can be installed in the form of Expanded Polystyrene (EPS) with approximately R-4 per inch, Extruded Polystyrene (XPS) with R-5 per inch or Polyisocyanurate (PIC) with approximately R-6 per inch. The amount of exterior insulation required to reduce the amount of interior vapor control depends on the climate and framing width (2x4 or 2x6 framing).

High density (2lb/ft3) closed cell spray foam can be used on the interior of non-insulating sheathing as a replacement for insulating sheathing in a “flash and batt” or “flash and blow” application. For example, in Zone 6, high density spray foam with an R-value of 11.25 or more can be used on the interior cavity side of exterior OSB sheathing installed on a 2x6 framed wall with the remainder of the cavity insulated with a fiberglass batt or cellulose and a Class III vapor control layer.

Installing the incorrect vapor control layer in the incorrect location can lead to premature enclosure failure, however, it is very important to remember that air leakage is usually a far more powerful mechanism of water vapor movement (see BSD-106: Understanding Vapor Barriers).