“If there is a pile of manure in a space, do not try to remove the odor by ventilation. Remove the pile of manure.”

Max von Pettenkofer, 18581

Gotta love those Germans. Especially the really old ones. Got it right big time. Dilution is not the solution to indoor pollution. Any powerful contaminant will overpower your ability to dilute it. Source control, source control and source control.

A ventilation system will not save you if you do stupid things. Like air sealing a building with a wet basement or one that is filled with “bad stuff” like insulation that is filled with rat droppings, bat droppings, mice droppings or other critter stuff and body parts either living or dead. Or worse—air seal a building where you store all manner of cleaning stuff, paint stuff, car stuff, wood finishing or stripping stuff, machinery stuff and carburetors.2 And even still worse—building the building out of stuff that does not stay in the stuff and then filling the building with our stuff that has stuff in it that does not stay in the stuff.3

We are getting very good at building tight enclosures by wrapping them with fully adhered membranes and all manner of other things (Photographs 1, 2 and 3)—and retrofitting old ones and getting them tight—especially when we use spray polyurethane foam (SPF) (Photograph 4). With tight building enclosures we sure end up with problems if we don’t deal with the obvious…and deal with the obvious in the obvious way.

Photograph 1 (left): Ultra Tight House – Advanced frame house sealed with a fully adhered exterior air control layer installed over structural sheathing yields an enclosure with a leakage rate less than 0.5 ach@50 Pa as tested under pressurization or depressurization. Photograph 2 (right): More Ultra Tight House – Continuous exterior insulation installed over fully adhered exterior air control layer to control condensation at the exterior air control layer – structural sheathing interface. Note that the garage is not attached to the house. Good idea, but typically not possible.

Photograph 3: Completed Ultra Tight House – Looks like any other house, just tight and ventilated right. Balanced fully ducted heat recovery ventilator with sealed combustion appliances and powered make-up air when air consuming appliances are used. OK, it doesn’t quite look like any other house because of the PV array and solar thermal stuff. This is the NIST Zero Energy Demonstration House in Gaithersburg, MD.

Photograph 4: Spray Polyurethane Foam Attic Retrofit – This is a phenomenal approach to air sealing a building and saving energy. Because of its very effectiveness a ventilation system needs to be installed in conjunction with the work and source control needs to be employed. Don’t be stupid. You can’t have civilians in the house when the SPF is being applied and the workspace needs to be ventilated during application and after application as you would (“should”) when repainting a room or installing new carpet or gluing down flooring or any VOC intensive work. You can’t leave existing ceiling insulation in place because of the junk that is in it that has accumulated over countless decades. You have to clean these old insulated surfaces to get rid of the bad stuff. Get rid of standard combustion appliances - install sealed combustion appliances. And for Pete’s sake fix the wet basement before you do the work in the attic.

We can go into someone’s house today and seal the underside of attic roof sheathing with SPF and do the basement rim joists and reduce leakage by a factor of 2 to 3. But doing that in someone’s house and leaving existing insulation in the ceiling in place is just plain dumb. Or even dumber is doing the deed and not replacing the combustion appliances to make them sealed combustion and adding a ventilation system. Or not fixing the wet basement or isolating the garage. Or worst of all doing the work when folks are in the house. You can’t fix stupid.

We can build a house so tight even Germans would be impressed (see Photograph 1 again). And then we forget about how to deal with a clothes dryer. Or we put in a kitchen range hood. Or we build a house with a fireplace. Or then we attach a garage. What are the odds that a house will have a clothes dryer, a kitchen range hood, a fireplace or an attached garage? I have news for you installing a cheap exhaust fan does not fix things. Installing an expensive one does not fix things either. Sucking does not work. Sucking causes air to come into your building through places you probably don’t want air to come through while carrying stuff or picking up stuff you don’t want inside your building. Sucking also causes bad things to happen to other things in your house like water heaters and furnaces and boilers and fireplaces. If you suck you have to blow or you are doomed. And the more you suck the more you have to blow – especially in a tight house. But first you do the source control. I think I said that already.

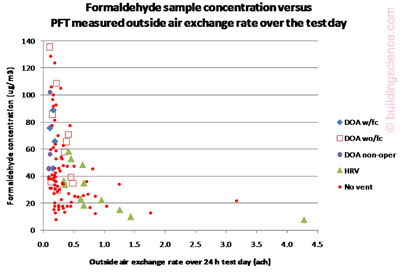

Some contaminants do not respond to dilution ventilation at the rates we typically deal with in houses. Formaldehyde is a case in point. At ventilation rates less than 0.5 air changes per hour (ach) there is no correlation between ventilation rate and concentration (Figure 1). As air change is increased and formaldehyde concentrations are reduced by dilution emission rates are simultaneously increased. The faster you dig in a sand pile the more sand comes poring in. There is no way to win with formaldehyde unless you don’t put it in the building in the first place or seal it up so it does not get out of the stuff you put in the building or build the building out of. Why not just double or triple the ventilation rates? Sure. Spoken like a true believer or Kool-Aid drinker. Rates like that don’t work because we can’t afford them and folks won’t accept them. Good luck trying to sell 1.5 ach or higher as a standard or a practice or a code. The best way is don’t put formaldehyde emitting stuff in your building or let formaldehyde emitting stuff emit. Dilution will not help you at the rates that are practical to dilute at.

Figure 1: Formaldehyde vs. Air Change - There is no discernable correlation between ventilation and formaldehyde concentration at air change rates reasonably expected in dwellings. Data source: Appendix E – Tables E-15 and E-17 and E-24 and E-25 from Offermann, F. J., Ventilation and Indoor Air Quality in New Homes, California Air Resources Board and California Energy Commission, PIER Energy-Related Environmental Research Program. Collaborative Report, CEC-500-2009-085, November 2009.

So how to do source control in a real building? Guess what? The “Indoor airPlus” specifications section4 brought to you courtesy of the US Environmental Protection Agency is a great place that tells you how to get it done. It does not deal with occupant stuff – the stuff occupants bring into their houses or the stupid stuff occupants do in their houses—but it does deal with the stuff you build the building out of. Nice job EPA folks.

I have already ranted about filling your place to keep stuff with stupid stuff and doing stupid stuff inside. Don’t do it. Can’t say much more than that. I am also not going to rant about the need for sealed combustion appliances and the need to make basements dry. Been there and done that already.5 Just do it.

What do I do when I have this beautiful enclosure constructed out of good stuff that is tight and I want to ventilate it right and have clothes dryer, a kitchen range hood, a fireplace and an attached garage? A lot of you are not going to like what I am going to say. Sorry in advance. Gulp.

I am going to start with garages. The absolute best way to deal with a garage is not to attach it to the house. OK, I said it. I know that is not a practical answer, but it is what it is. So what about attached garages? Now it gets ugly. If you build to code you will get consistently below 3 ach@50 Pa and if you now install an exhaust only ventilation system at the rates you are required to ventilate at you will pull stuff out of the attached garage and into the house.

Good luck with trying to isolate the garage by constructing the demising wall/floor/whatever “tight enough.” Not going to happen. And trying to do pressure diagnostics to verify a “tight enough” demising wall using some arbitrary and capricious ratio/value/test procedure ranks right up there with most hygrothermal simulations. The take away is don’t suck on the house and you will not end up sucking on the garage.6

Attached garages mean you had better install balanced ventilation systems or supply ventilation systems in houses and call it a day.7 It is possible to make the garage more negative than the house even if it has an exhaust only ventilation system by sucking on the garage all the time by installing a continuously running exhaust fan in the garage – but really? Are we prepared to go that far to compensate for the inherent deficiencies of exhaust only ventilation?

If you don’t suck on the house storing bad stuff in the garage is now better than storing bad stuff under the kitchen sink or in a closet or in the basement. Of course, if you have a machine shop in your garage you need to provide a ventilation system for the garage even if you have a balanced ventilation system or supply ventilation system in the house.8

Kitchen range hoods are both beautiful things and ugly things at the same time. They can backdraft anything and everything. They need make up in today’s houses or yesterdays houses that we have tightened. Can’t be any more straight forward than that. So how to do it? Now would be a good time to read Chapter 33 “Kitchen Ventilation” of 2011 ASHRAE HVAC Applications. I will confess that I didn’t when I first started dealing with these issues and learned the lessons the hard way.

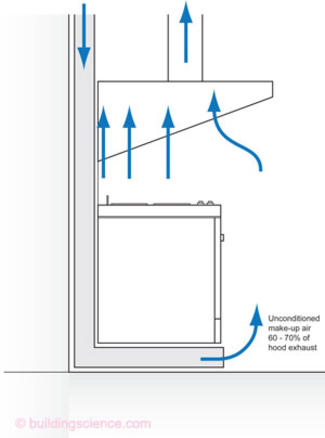

Lets say that you have a 1,000 cfm kitchen exhaust hood going into a tight house. Happens all the time. When the exhaust hood is operating you can suck a golf ball down a garden hose with the resulting negative pressure. The first thing we make sure of is that the exhaust hood actually works to capture the effluent. The hood must overhang the cooking surface big time. The absolute best approach is to use a backshelf hood with side panels and large over hangs on both sides and the front (Figure 2). Nothing new here – read Chapter 33.

Now we need make-up air. When dealing with large hoods (greater than 400 cfm) we recommend providing two kinds at the same time but at different places. First we provide direct make-up air using a modified backwall approach such that this make-up air is introduced at floor level (Figure 2). This direct make-up air introduced at floor level should never provide more than 60 to 70 percent of the hood exhaust. So for our 1,000 cfm exhaust our direct make-up air flow should be between 600 and 700 cfm. This air is rarely conditioned – except when we deal with rich clients in Aspen or Naples.9 If you can’t stand the heat get out of the kitchen is based on reality.

Figure 2: Capture the Effluent - The first thing we make sure is that the exhaust hood actually works to capture the effluent. The hood must overhang the cooking surface big time. The absolute best approach is to use a backshelf hood with side panels and large over hangs on both sides and the front. Backshelf hoods can typically use 30 percent less exhaust to capture bad stuff compared to other hoods. Side panels can get you another 30 percent improvement. Note the direct make-up air using a modified backwall approach such that this make-up air is introduced at floor level. This direct make-up air introduced at floor level should never provide more than 60 to 70 percent of the hood exhaust. Why? Ah, we need a zone of negative pressure around the cooking surface – you don’t want to push the bad stuff, you want to pull the bad stuff.

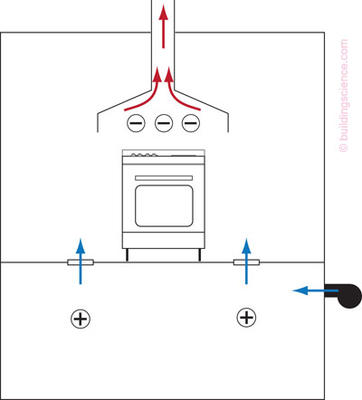

Note that at this point we have only satisfied 60 to 70 percent of the make-up air requirement. We now provide a second system that meets the rest – plus a little bit – and this air is typically preconditioned. In our example we now provide around 350 to 400 cfm of conditioned make-up air at the perimeter of the kitchen area (Figure 3). We “suck” at the center and “blow” at the perimeter. The exhaust hood and the make-up air systems are interlocked. When they are operating the rest of the house does not know they are there. We in essence have uncoupled the kitchen from the rest of the building HVAC systems. We condition the kitchen cooking area with the house HVAC system pretending that the cook top/oven and range hood are not there.

Figure 3: Satisfaction – We satisfy 60 to 70 percent of the make-up air requirement with the modified backwall approach introducing air at floor level (the “blue arrows” at the lower grilles on each side of the appliance). We now provide a second system that meets the rest – plus a little bit (around 350 to 400 cfm) – and this air is typically preconditioned and introduced at the ceiling at the perimeter of the kitchen area (the “blue arrows” coming from the two ceiling registers). We “suck” at the center of the space at the appliance and “blow” at the perimeter. The exhaust hood and the two make-up air systems are interlocked. When they are operating the rest of the house does not know they are there. We in essence have uncoupled the kitchen from the rest of the building HVAC systems (the “black dashed arrows” entering from the floor registers and leaving up high on the wall). We condition the kitchen cooking area with the house HVAC system pretending that the cook top/oven and range hood are not there.

When we condition this air in hot humid climates we typically size the system at around 1 ton of capacity for every 200 cfm of make-up air. So for our example we need a 2-ton system.

This is not cheap. But if you want a 1,000 cfm kitchen range hood in a tight house this is what you have to do. Ouch.

But what if I only have a 200 cfm kitchen range hood? It gets easier. Check out Figure 4. We interlock the range hood exhaust with a supply fan that provides make-up air at roughly a 10 percent greater flow rate than the hood exhaust rate. This make-up air is typically provided in a separate zone like a basement that provides ample tempering of the make-up air by mixing. It then is introduced via floor registers adjacent the cook surface. The zone around the appliance needs to “suck” but the rest of the space blows or is neutral. The 10 percent greater flow rate works because this air is not directly introduced under the appliance but into the adjacent zone and moves into the cooking area as transfer air.

Figure 4: Smaller Hoods Are Easier – With a 200 cfm kitchen range hood we interlock the range hood exhaust with a supply fan that provides make-up air at roughly a 10 percent greater flow rate than the hood exhaust rate. This make-up air is typically provided in a separate zone like a basement that provides ample tempering of the make-up air by mixing. It then is introduced via floor registers adjacent the cook surface. The zone around the appliance needs to “suck” but the rest of the space blows or is neutral. The 10 percent greater flow rate works because this air is not directly introduced under the appliance but into the adjacent zone and moves into the cooking area as transfer air.

We provide clothes dryer make-up air the same way. And we do the same for fireplaces. We use separate powered make-up air for each appliance. Makes the controls easy. We like the transfer air approach – air coming from a different zone where it is tempered by mixing with air in that space. I know what you are saying….a make-up air fan for the kitchen range hood, another one for the vented clothes dryer, and still another one for the fireplace? Sounds like a lot of fans to me? Yup. I told you that you would not be happy. But that is where we have ended up – at least at our firm.

I sure do miss the old days where you could open a window to make the fireplace work and no one had kitchen range hoods and we used clotheslines not dryers. I miss it all except the part where I smelled like machine oil when I went to grade school.

Footnotes:

Hat tip to David Baylon and Bud Offermann for this quote that is rumored to have come across the ocean by way of the legendary wine connoisseur Ole Fanger. Professor Fanger carried a gold thermometer in his pocket always at the ready to make sure wine was served at the right temperature in between educating the rest of us on odors. You are missed Professor.

Dad used to rebuild them. He was always cleaning them in the basement laundry tub by soaking them in stuff that I am sure can’t be exported to North Korea. Drove mom crazy. Dad had a half-built one-man jet helicopter that he was always working on in the basement. To get it out he had to knock a huge hole in the wall that separated the basement from the garage. He found the opening convenient so he never repaired it because he could easily get from the house to his machine shop in the garage without going outside. I know first hand about garage to house contaminant transport issues.

Apologies to George Carlin and his fabulous quote: “A house is just a place to keep your stuff while you go out and get other stuff.” I don’t think it is right or just or makes sense to set ventilation rates to deal with 5 percent of the population that wants to do stupid things and will continue to do stupid things no matter what. Yes, it is their Constitutional Right (the Charter of Rights covers this in Canada) to be stupid. I think it is the 30th Amendment. But I don’t think the rest of us should pay for their stupidity. You want to fill you house with stupid smelly stuff? Go ahead. You want to store a chemistry set under your kitchen sink that junior can make napalm or nerve gas out of? Go ahead. You want to strip furniture in your bedroom? Go ahead. But don’t expect me to have to design and construct ventilation systems to save you from yourself at the expense of having to force everyone else to do the same thing. Of course this is just I dream of mine. In the meanwhile as an engineer I will continue to design ventilation systems to meet the current standard of care. I will whine about it, but still suck it up and get on with it. Stupid should hurt. It should hurt the stupid person. Unfortunately it hurts most of us who are not stupid.

http://www.epa.gov/iaplus01/pdfs/construction_specifications.pdf

BSD-103: Understanding Basements and BSI-035: We Need to do it Different This Time

Or the crawlspace, or the slab, or the basement. You only suck on a building if you think radon is valuable and you want to mine it

Also make sure that you do not create negative pressures because you have done dumb things with your duct systems like installing leaky ductwork in vented attics, vented crawlspaces or using building cavities as returns.

I really have a strong opinion on the machine shop garage ventilation thing – to this day I never ever will willingly fly in a helicopter.

I do more than my share of high end custom home stuff in extreme climates like Aspen, CO and Naples, FL. Usually, my clients have homes in both places plus a home somewhere else out of the country for tax purposes and an apartment in NYC that they fly to in their private jets worrying about their carbon footprints.