Airtight homes require rational and predictable ventilation. A key gap and area of ongoing research is to allow credit for better performing ventilation systems, such as supply and balanced ventilation compared to exhaust, and systems with predictable filtration of outside air and recirculation filtration. This would yield energy savings and reduced moisture control risk in humid climates, without compromising indoor air quality relative to the least performing system allowed by ASHRAE Standard 62.2. Building on previous research dealing with ventilation air distribution, this study added new elements of ventilation effectiveness research, accounting for source of outside air, particle contaminants, and VOC contaminants.

Executive Summary

Airtightness of new homes is critical to achieving low-energy consumption, healthy and comfortable spaces, and durability. Airtight homes require rational and predictable ventilation. A key gap and area of ongoing research is to allow credit for better performing ventilation systems, such as supply and balanced ventilation compared to exhaust, and systems with predictable filtration of outside air and recirculation filtration. This would yield energy savings and reduced moisture control risk in humid climates, without compromising indoor air quality relative to the least performing system allowed by ASHRAE Standard 62.2. Building on previous research dealing with ventilation air distribution, this study added new elements of ventilation effectiveness research, accounting for source of outside air, particle contaminants, and VOC contaminants. These new data give further support for ventilation rate credit for better performing ventilation systems. The intended result is to provide specific guidance for understanding whole-building ventilation system effectiveness, which is critical to promoting the best low energy and high value ventilation solutions.

ASHRAE Standard 62.2-2010 may be considered to contain the "standard of care" for ventilation system design and operation in residential buildings, yet there are considerable technology gaps with that Standard. ASHRAE Standard 62.2 uses a catch-all approach that assumes that the entire house is a single, well-mixed zone and that there is no difference between different whole-building ventilation systems in providing effective ventilation. In other words, it does not differentiate between better and worse performing whole-building ventilation systems and the rates set are inferred to be adequate for the worst performing system. To try to facilitate that assumption, the ventilation rate has to be high enough to accommodate the worst performing system, which is single point exhaust.

The study focused on the in-situ impacts of various ventilation systems including the impacts of differing sources of outside air and the spatial distribution and filtration of ventilation air. The project involved testing two unoccupied, single-family, detached homes in Tyler, TX that were constructed as lab homes at the University of Texas – Tyler1. The twin lab homes at UT-Tyler offered a unique opportunity for the direct comparison of nearly identical homes except for one having a vented attic and the other having an unvented attic assembly (also known as sealed cathedralized attic).

Exhaust ventilation testing showed lower uniformity of outdoor air exchange rate between living space zones, and higher concentrations of particulates, formaldehyde and other Top 20 VOCs than did the supply and balanced ventilation systems. This showed that single-point exhaust ventilation was inferior as a whole-house ventilation strategy. It was inferior because the source of outside air was not directly from outside (much of it came from the attic), the ventilation air was not distributed, and no provision existed for air filtration. Indoor air recirculation by a central air distribution system can help improve the exhaust ventilation system by way of air mixing and filtration. In contrast, the supply and balanced ventilation systems showed that there is a significant benefit to drawing outside air from a known outside location, and filtering and fully distributing that air.

The central-fan-integrated supply (CFIS) ventilation system showed an 85% and 73% reduction in 0.3-2.0 micron particles for House 1 and House 2, respectively, attributable to recirculation air filtration by operation of the central air distribution system.

Total Volatile Compound (TVOC) data showed that, compared to the Exhaust system, the CFIS and ERV ventilation systems reduced TVOC by 47% and 57%, respectively, averaged between the two houses. Compared to the Baseline tests, the Exhaust system increased TVOC by 37% in the House 1 Main zone, and increased TVOC by 18% in the House 2 Master zone. This highlights that the unknown air path, or source of outside air, for the Exhaust ventilation system can cause indoor air to be more contaminated depending on what contaminants are picked up on the way in.

Ventilation System Factors developed in this study could be applied to allow accounting for ventilation system attributes that improve the system’s performance. While analysis did not quantify the collective effect of reduced contaminant exposure to occupants, engineering judgment can be applied based on the quantitative results of the individual factors. Engineering judgment is valid here since the ASHRAE Standard 62.2 ventilation rates are themselves based only on the engineering judgment and experience of the committee members, not on any health or medical studies. Values for percent reductions in ventilation airflow were assigned for each system improvement that exists for a given ventilation system. These values were then summed to give a total percent reduction. The individual system improvements were based on four System Factor Categories: Balance, Distribution, OA Source, and Recirculation Filtration. Application of the System Factors is recommended for consideration in the DOE Building America and Challenge Home programs to allow credit for better performing ventilation systems. This would yield energy savings and reduced moisture control risk in humid climates, without compromising indoor air quality relative to the worst performing system allowed by ASHRAE Standard 62.2-2010. Such ventilation rate credits would also benefit the EPA Indoor Air program required by the DOE Challenge Home.

1 Problem Statement

1.1 Introduction

This study focuses on the in-situ impacts of various ventilation systems including the impacts of differing sources of outside air and the spatial distribution and filtration of ventilation air. The project involved testing two unoccupied, single-family, detached homes in Tyler, TX that were constructed as lab homes at the University of Texas – Tyler2. The twin lab homes at UT-Tyler offered a unique opportunity for the direct comparison of nearly identical homes except for one having a vented attic and the other having an unvented attic assembly (also known as sealed cathedralized attic).

1.2 Background

The residential building sector consumes approximately 21% of the primary energy used in the United States (DOE/EIA 2008). Energy consumption due to ventilation needs is increasingly becoming a high percentage of total space conditioning energy consumption. Accounting for better performing ventilation systems is a reasonable step in the effort to reduce energy consumption without compromising indoor air quality, comfort, or durability.

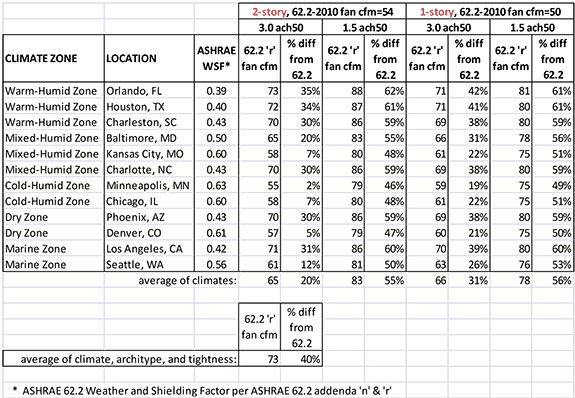

Airtightness of new homes is critical to achieving low-energy consumption, healthy spaces, and durability. Airtight homes require rational and predictable ventilation. A key gap and area of ongoing research is enabling a reduction of ventilation airflow relative to ASHRAE Standard 62.2-2010 addendum ‘r’ (having about 40% higher airflow requirement relative to before addendum r; see Figure 1) to reduce energy consumption, improve humidity control performance, and improve indoor air quality over a time scale less than annual average. Identifying methods to achieve such reductions would benefit the EPA Indoor Air program required by the DOE Challenge Home. Research should be conducted into methods that include considerations for:

- Accounting for the quality of the source of outside air for different ventilation systems types.

- Accounting for ventilation air distribution effectiveness.

- Managing hazardous indoor air pollutants in ways other than air change.

Figure 1. Calculations showing that ASHRAE Standard 62.2-2010 addenda 'r' ventilation fan airflow rates are about 40% higher than before addenda 'r', averaged over a range of climates, building archetypes, and building air tighness

1.2.1 Relevant Issues with ASHRAE Standard 62.2

ASHRAE Standard 62.2-2010 may be considered to currently contain the “standard of care” for ventilation system design and operation in residential buildings, yet there are considerable technology gaps with that Standard. ASHRAE Standard 62.2 uses a catch-all approach that assumes that the entire house is a single, well-mixed zone and that there is no difference between different whole-building ventilation systems in providing effective ventilation. To try to facilitate that assumption, the ventilation rate has to be high enough to accommodate the worst performing system, which is single point exhaust. Utilizing high performing systems that draw outside air from a known fresh air location and filter and fully distribute that air to the occupants breathing zone (including bedrooms where occupants spend the most continuous time) should allow optimization of the ventilation rate to avoid the energy consumption and moisture control problems of over-ventilation. The ventilation rates in ASHRAE Standard 62.2 are currently based entirely on the collective engineering judgment of the committee members. They are based on committee member’s notions of what they feel good about based on their own experience and judgment in view of information they are currently aware of. There is no published basis for the rates in any health or medical study. Using engineering judgment based on new information, such as in this study, to make adjustments to numbers that are themselves based on engineering judgment is appropriate.

In accounting for intermittent versus continuous ventilation, ASHRAE Standard 62.2 uses relative annual average dose to a generic contaminant as the only metric to allow for a performance-based compliance approach and to account for intermittent versus continuous ventilation. That metric may be valid for avoiding exposure to contaminants that may cause cancer over 20 years, but that metric completely ignores shorter term odor, moisture, and sensory irritation effects which is really the only obvious metric occupants have available to determine their satisfaction level with indoor air. While the available medical science for cancer causing chemical contaminants at concentrations typically found in residential environments is almost non-existent, the science for shorter term asthma and allergy response is better known (Carl- Gustaf Bornehag et al. 2004). Occupant observation of objectionable odor, visible moisture or mold caused by that moisture, and sensory irritation is overt. Those overt objections are what home builders have to deal with even though ASHRAE Standard 62.2 primarily does not.

Source of Outside Air

ASHRAE Standard 62.2-2010 requires that supply and balanced ventilation systems draw outside air directly from a known fresh air location but does not include any such requirement for exhaust ventilation systems. Therefore make up air for exhaust ventilation air comes from the paths of least resistance, which could be through a garage, attic, crawlspace, basement, or other soil contact location. To be consistent, at the very least the Standard would need to require intentional makeup air inlets, or, much better, require a supply system that provides makeup air from a known fresh air location whenever the whole-building exhaust ventilation system was operating.

In contrast, the following building codes have provisions requiring direct outside air for all ventilation systems: the International Mechanical Code, the Washington State Ventilation and Indoor Air Quality Code, the U. S. Housing and Urban Development Code, and the National Building Code of Canada. A brief description of those requirements follows:

IMC 2012: The IMC 2012 requires a balanced ventilation system with outdoor supply air approximately equal to exhaust air.

WAVIAQ Code 2009: The WAVIAQ Code 2009 requires that ventilation systems must have direct outdoor air inlets, and that they be screened and located so as not to take air from a list of contaminated areas, including areas where odors may be objectionable, attics, crawlspaces, or garages.

HUD Code 2008: The HUD Code requires that the ventilation system be balanced, and designed to exchange air directly with the exterior of the home. It specifically prohibits air drawn from the space underneath the home, through the floor, walls, or ceiling/roof systems.

NBC 2005: The NBC 2005 stipulates that outside air supply be provided and connected directly to outside.

Ventilation Effectiveness

In terms of ventilation effectiveness, ASHRAE Standard 62.2 accounts only for temporal (time based) effectiveness over an annual average; there is no provision for spatial (space-to-space) ventilation distribution effectiveness, or system effects. In other words, ASHRAE Standard 62.2 accounts for ventilation effectiveness only in regards to system runtime. Even so, while the maximum ventilation air delivery cycle time is truncated to one day, the runtime effectiveness values are based on calculations that would allow the ventilation system to be off for months without any decrease in effectiveness, because the evaluation metric is locked to relative annual average exposure to a generic contaminant3. That approach ignores shorter term indoor air quality effects of odor and sensory irritation, which are nevertheless stated parts of an acceptable indoor air quality approach in the ASHRAE Standard 62.2 Scope, and definitions of “acceptable indoor air quality” and “air cleaning.”

In contrast, the following building codes have provisions requiring ventilation air distribution for all ventilation systems: International Mechanical Code, Minnesota Building Code, Washington State Ventilation and Indoor Air Quality Code, the U. S. Housing and Urban Development Code, and the National Building Code of Canada. A brief description of those requirements follows:

IMC 2012: The IMC requires an approximately balanced ventilation system with the ventilation supply system designed to deliver the required rate of outdoor airflow to the breathing zone within each occupiable space. The WAVIAQ Code requires the introduction and distribution of outdoor air and the removal of indoor air by mechanical means. It further requires that outdoor air be distributed to each habitable room by means such as individual inlets, separate duct systems, or a forced-air system.

MBC 2009: The MBC requires ventilation air distribution and circulation such that outdoor air is delivered to each habitable space by a forced air circulation system, separate duct system, individual inlets, or a passive opening. When outside air is directly ducted to a forced air circulation system, circulation of 0.075 cfm/ft2 must be maintained on average each hour. When outside air is not directly ducted to a forced air circulation system, circulation of 0.15 cfm/ft2 must be maintained on average each hour.

WAVIAQ Code 2009: The WAVIAQ Code requires the introduction and distribution of outdoor air and the removal of indoor air by mechanical means. It further requires that outdoor air be distributed to each habitable room by means such as individual inlets, separate duct systems, or a forced-air system. Conflictingly, in homes with exhaust only ventilation systems without outdoor air inlets the home must have a ducted forced air heating system that communicates with all habitable rooms and the interior doors must be undercut to a minimum of ½- inch above the surface of the finish floor covering; however, nothing is mentioned about a minimum interval of ducted forced air heating system communication with all habitable spaces. This will typically leave days and weeks on end with minimal ventilation air distribution.

HUD Code 2008: The HUD Code requires that ventilation system be designed to ensure that outside air is distributed to all bedrooms and main living areas.

NBC 2005: In the NBC, for ventilation systems not used in conjunction with a forced air heating system, an outside air supply ventilation fan is required with the same rated capacity as the principle [exhaust] ventilation fan to distribute outside air directly to all bedrooms through a system of supply ducts. Where an exhaust-only system is installed via the principal ventilation fan, the exhaust fan control must be wired so that activation of the exhaust fan automatically activates the circulation fan of the forced air distribution system required at its rated capacity but not less than 5 times the rated capacity of the exhaust fan. Alternately, interlocking the forced air distribution system's circulation fan with the principal [exhaust] ventilation fan can be accomplished where the forced air distribution system is equipped with a control that automatically activates the circulation fan at user- selected intervals. ASHRAE Standard 62.2 does not attempt to address the issue of delivery of outdoor airflow to each space, or to the breathing zone within each occupiable space, or forced air circulation/distribution of ventilation air. It simply makes an over-reaching assumption that for all ventilation system cases, the entire house is a single, well-mixed zone, focusing only on relative annual average exposure.

1.2.2 Research Questions

The research presented in this report is intended to help develop a better understanding of whole- building ventilation system effectiveness and distribution in low energy homes which is critical to promoting the best low-energy and high-value ventilation solutions. BSC seeks to address the following research questions:

- Do different whole-building ventilation systems perform significantly differently in terms of their ability to deliver uncontaminated ventilation air to the occupants?

- What measurements and testing protocols are needed to appropriately account for the source of outside air relevant to occupant exposure to chemical and particulate contaminants and their expected satisfaction with indoor air in residential environments?

- What is the overall indoor air quality impact of operating an exhaust whole-building ventilation systemversus supply and balanced ventilation?

- For whole-building ventilation systems that do not draw outside air directly from a known fresh air source, how much of the ventilation air is drawn through potentially contaminated adjacent spaces such as garages and vented attics?

- What is the impact of drawing outdoor air through the building enclosure and adjacent unoccupied spaces on the level of particulate contaminants within the conditioned space?

- What is the level of chemical contaminants within the conditioned space and adjacent spaces, and the impact of drawing outdoor air through the building enclosure and adjacent unoccupied spaces? What is the impact of drawing outdoor air through the building enclosure nd adjacent unoccupied spaces on the level of chemical contaminants within the conditioned space?

- Does the testing and modeling conducted provide justification for lower ventilation rates for fully-distributed whole-building ventilation systems drawing outside air from a known fresh air location compared to lower performing systems?

1.3 Relevance to Building America’s Goals

Overall, the goal of the U.S. Department of Energy's (DOE) Building America program is to “reduce home energy use by 30%-50% (compared to 2009 energy codes for new homes and pre- retrofit energy use for existing homes).” To this end, we conduct research to “develop market- ready energy solutions that improve efficiency of new and existing homes in each U.S. climate zone, while increasing comfort, safety, and durability.”4

The combination of air-sealed building enclosures and controlled mechanical ventilation is an effective means to reduce energy consumption while providing improved indoor air quality and comfort in residential buildings. The results of this research project will further inform the residential building community on how effective different whole-building ventilation systems are in meeting these necessary goals. The results presented here provide new data on in-field performance of mechanical ventilations systems. They are intended to provide specific guidance for understanding whole-building ventilation system effectiveness, including the impacts of ventilation air distribution, the source of outside air, and particulate and VOC contaminant levels. This is critical to promoting the best low energy and high value ventilation solutions.

1.4 Cost-Effectiveness

Ventilation energy consumption is a significant part of the energy consumption and energy cost of low energy homes. Understanding whole-building ventilation system performance in low energy homes is critical to promoting the highest value ventilation solutions for reducing energy consumption while providing good indoor air quality and comfort for the occupants. Over- ventilation unnecessarily consumes energy and raises the risk of comfort and indoor air quality problems due to elevated indoor humidity in warm-humid climates. Higher performing ventilation systems may be able to eliminate unnecessary over-ventilation, thereby providing equal or improved indoor air quality and comfort at lower cost.

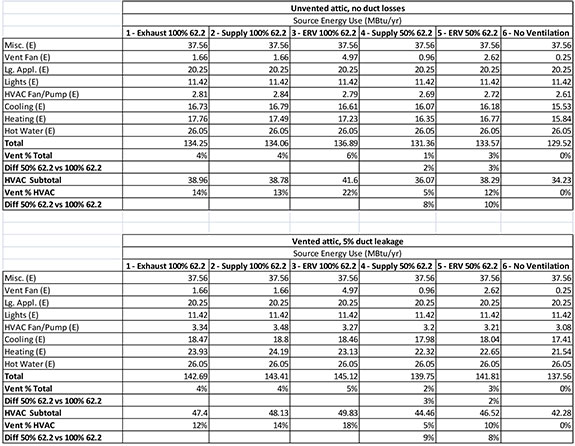

The BEopt™ (Building Energy Optimization) software provides capabilities to evaluate residential building designs and identify cost-optimal efficiency packages at various levels of whole-house energy savings (Christensen 2006). Table 1 shows results from BeOpt simulations of the 1475 ft2 UT-Tyler houses with an unvented attic and a vented attic. Energy consumption is listed by end-use for different ventilation systems, and for ventilation airflow rates equal to the ASHRAE Standard 62.2-2010 rate and 50% of that for systems that draw the outside air from a known fresh air location, filter, and fully distribute that ventilation air to the breathing zone of the occupants. Energy cost was calculated at a rate of $0.103/kWh. BeOpt simulations for the UT-Tyler Houses projected that ventilation accounts for 4% - 6% of total energy consumption, and that ventilation accounts for 12% - 22% of HVAC energy consumption. Reducing the ASHRAE 62.2-2010 ventilation rate by 50% (the basis for this is provided in section 5) was projected to reduce HVAC energy used for conditioning ventilation air by 8% to 10%, and was projected to reduce total energy consumption by 2% to 3%. With ASHRAE 62.2-2010 addendum 'r' ventilation rates being about 40% higher than before addendum 'r', if Energy Star and the DOE Challenge Home programs were to reference the addendum r rates, then the savings would be higher.

Table 1. BeOpt simulations of the UT-Tyler houses with unvented attic and vented attic, showing energy consumption by end-use for different ventilation systems and ventilation airflow rates . . .

Download the complete report here.

Footnotes:

- Learn more at www.UT Tyler.edu/TxAIRE/Technology/Houses

- Learn more at www.UT Tyler.edu/TxAIRE/Technology/Houses

- Relative annual average dose is the only metric used in ASHRAE Standard 62.2 for the performance based compliance method and to calculate intermittent ventilation effectiveness factors. The method tracks a generic contaminant (rather than any specific contaminants) and compares the annual average dose of the generic contaminant (in an assumed single-zone, well-mixed building model) using an actual continuous or intermittent ventilation air exchange rate relative to a reference continuous air exchange rate.

- http://www1.eere.energy.gov/buildings/building_america/program_goals.html