Basements are part of a home, within the building boundary—despite repeated attempts over the years to disconnect them from the living space. Because of this, basements should be designed and constructed to be dry and conditioned. This is particularly important for basements that contain mechanical equipment—a situation that is practically guaranteed in buildings that have a basement. Mechanical systems must not be installed outside of a home in unconditioned space unless there is no practical alternative.

A dry basement or crawlspace is less likely to have pests and termites. If a basement is being used for storage or as living space, it needs to be kept dry to avoid mold and dust mites.

The most important strategies for keeping basements dry are those of groundwater and rainwater control. Refer to Information Sheet 101: “Groundwater Control” for further guidance. Once these groundwater control strategies are employed, the basement should be insulated to minimize cold surfaces that can condense water and elevate local relative humidity.

Basements should be insulated on their perimeters—they should not be insulated between floors.

Walls

Basement walls should be insulated with non-water sensitive insulation that prevents interior air from contacting cold basement surfaces—the concrete structural elements and the rim joist framing. Allowing interior air (that is usually full of moisture, especially in the humid summer months) to touch cold surfaces will cause condensation and wetting, rather than the desired drying. The structural elements of below grade walls are cold (concrete is in direct contact with the ground)—especially when insulated on the interior. Of particular concern are rim joist areas—which are cold not only during the summer but also during the winter. This is why it is important that interior insulation assemblies be constructed as airtight as possible.

The best insulations to use are foam based and should allow the foundation wall assembly to dry inwards. The foam insulation layer should generally be vapor semi impermeable (greater than 0.1 perm), vapor semi permeable (greater than 1.0 perm) or vapor permeable (greater than 10 perm) (Lstiburek, 2004). The greater the permeance the greater the inward drying and therefore the lower the risk of excessive moisture accumulation.

Up to two inches of unfaced extruded polystyrene (R-10), four inches of unfaced expanded polystyrene (R-15), three inches of closed cell medium density spray polyurethane foam (R-18) and ten inches of open cell low density spray foam (R-35) meet these permeability requirements.

In all cases, a capillary break should be installed on the top of the footing between the footing and the perimeter foundation wall to control “rising damp.” It is also necessary to install a capillary break between the foundation wall and framing.

In certain situations, foil-faced insulations may be used on the interior of foundation walls. However, such requires careful attention to supplemental moisture management strategies. Consult the Builder’s Guide listed below for specific guidance.

In most basement wall situations, the foam plastic insulation material will need to be covered by a fire/ignition barrier. Half-inch gypsum board usually provides sufficient ignition barrier (check your local building code). When this ignition barrier is supported on a stud wall, the cavities of this wall may be filled with supplemental insulation. It is important that the airtight foam insulation assembly be continuous behind the framed wall. No interior vapor barriers should be installed in order to permit inward drying.

Floors

Basement floor slabs are best insulated underneath with rigid insulation: both extruded or expanded polystyrene have been widely used with success. Although the energy savings of sub-slab insulation are not as significant as basement wall insulation, such insulations do offer a significant improvement in comfort and moisture damage resistance (including against summertime condensation).

When slab insulation is provided, a sheet polyethylene vapor barrier should be located over the rigid insulation and in direct contact with the concrete slab. As the slab will only be able to dry upward, the slab should be allowed to dry before finishes are applied. Impermeable interior floor finishes such as vinyl floor coverings should also be avoided.

A sand layer should never be installed between the sheet polyethylene vapor barrier and the concrete slab. Sand layers located between the slab and the vapor barrier can become saturated with water, which are then unable to dry downwards through the vapor barrier. In this scenario, drying can only occur upward through the slab which typically results in damaged interior floor finishes (Lstiburek, 2002).

Basement Insulation Details

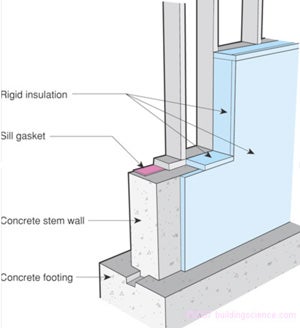

Figure 1

Rigid Insulation Wraps Concrete Surfaces

- Cold concrete foundation wall must be protected from interior moisture-laden air in summer and winter

- Rim joist assembly must be insulated with air impermeable insulation or insulated on the exterior

- Rigid insulation completely wraps exposed concrete preventing interior air from contacting potential concrete condensing surface

- Seams in rigid insulation and joints to other materials sealed to provide air barrier

- Rigid insulation is vapor semi-impermeable or vapor semi-permeable (foil facing or plastic facing not present)

- Rigid insulation provides bond break between foundation wall and slab when insulation is installed before slab is poured

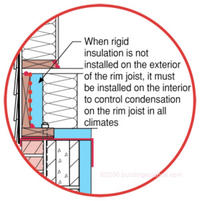

Figure 2

Interior Rim Joist Insulation

- Air barrier needed to protect the rim joist from interior moisture-laden air in summer and winter

- Seams in rigid insulation and joints to other materials sealed to provide air barrier

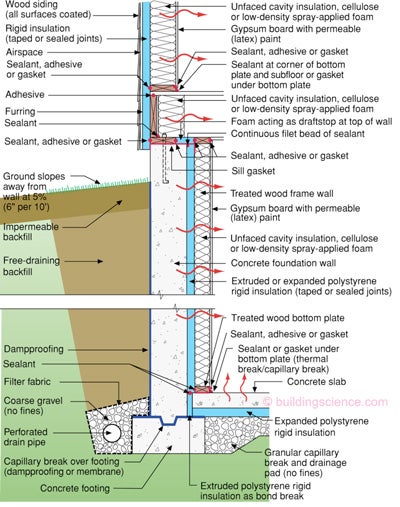

Figure 3

Rigid Insulation with Supplemented Insulated Frame Wall Assembly

- Rigid foam insulation board assembly must provide continuous air barrier and capillary break around concrete foundation

- Rigid insulation assembly must be continuous behind wood frame wall

- Rigid insulation is vapor semi-impermeable or vapor semi-permeable (foil facing or plastic facing not present)

- Wood frame wall cavity to be insulated with unfaced fiberglass or damp spray cellulose

- No interior vapor barrier installed

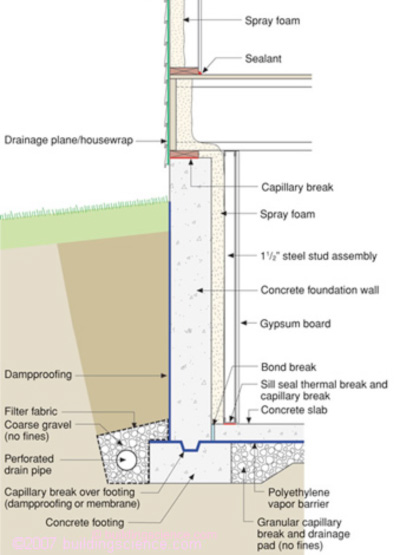

Figure 4

Interior Spray Foam Encapsulates Concrete Surfaces

- Least risky interior wall insulation approach

- Cold concrete foundation wall must be protected from interior moisture-laden air in summer and winter

- Rim joist assembly must be insulated with air impermeable insulation

- Interior air cannot access concrete condensing surface or rim joist condensing surface due to spray foam layer

- Spray foam insulation layer is vapor semi-permeable permitting inward drying

- Spray foam must be covered with fire/ignition barrier