When constructing unvented roofs with asphalt shingles in hot humid climates, a vapor barrier must be installed between the asphalt shingles and the roof deck. Asphalt shingles store water from dew (condensation due to night sky cooling) and rain. Asphalt shingles are a reservoir for water and behave similarly to traditional wood shingles and cedar shakes in that regard. With traditional wood shingle and cedar shake roofs, a receptor for this moisture is typically provided. This receptor is an air space that can be accomplished in a variety of ways.

When constructing unvented roofs with asphalt shingles in hot humid climates, a vapor barrier must be installed between the asphalt shingles and the roof deck. Asphalt shingles store water from dew (condensation due to night sky cooling) and rain. Asphalt shingles are a reservoir for water and behave similarly to traditional wood shingles and cedar shakes in that regard. With traditional wood shingle and cedar shake roofs, a receptor for this moisture is typically provided. This receptor is an air space that can be accomplished in a variety of ways (see, for example, Cedar Breather®).

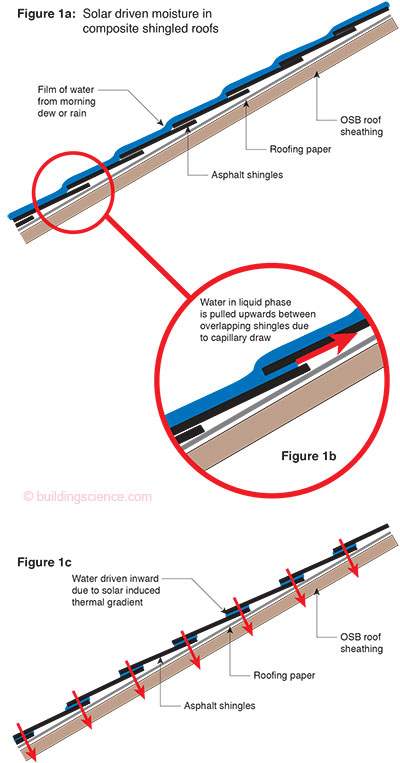

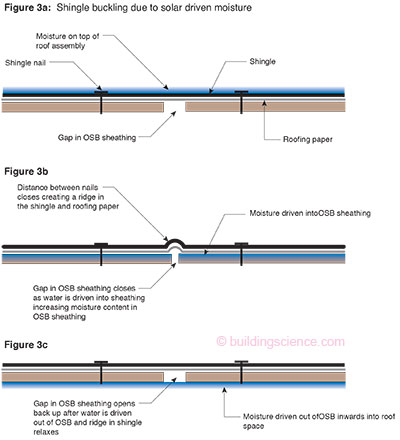

When a moisture reservoir is heated by the sun, water is driven inwards1. The driving forces for this phenomenon are extremely large, as indicated by the psychrometric chart (in fact, the vapor pressures are off the pyschrometric chart and steam tables must be consulted). In typical roof assemblies, this moisture is driven inwards through vapor permeable roofing papers/felts into plywood and OSB roof decks, and subsequently through the other side of the roof deck into the attic space. This phenomenon can typically be ignored in climates other than hot humid climates because the combination of extensive dew formation and solar heating at high outside ambient temperatures is not common. In vented roofs, this is often manifested in the buckling of shingles early in the morning as the moisture migrates in to the roof deck sheathing and the joints close. This is followed by relaxation and opening up of the roof sheathing later in the day—the buckling disappears. With unvented roof assemblies, this inwardly driven moisture must be addressed. The preferred method is to prevent the moisture from entering the roof deck material via the installation of a vapor barrier.

Asphalt shingles are quite impermeable to the passage of liquid water directly through them. However the geometry of their installation allows wicking at overlaps. (See Figures 1a, 1b, and 1c). This inwardly driven capillary water is the source for the wetting of the roofing underlayment and roof sheathing. The material properties of shingles change under elevated temperatures and moist conditions due to their hygroscopic nature. The large vapor pressures resulting from incident solar radiation and the changed material properties are sufficient to drive moisture inward through the shingles.

Roofing felts or underlayments vary greatly in their permeability to water vapor; the typical underlayment used under asphalt shingles in residential construction is quite permeable. In ASHRAE Fundamentals (2001), 15-lb asphalt felt has a wet-cup permeance of 5.6 and 15-lb tar felt is 18.2 perms. Some fiberglass reinforced underlayments have permeances as high as 28 (type of test not specified).

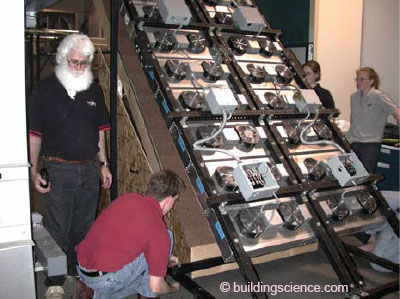

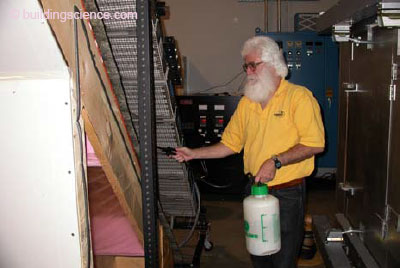

Building Science Consortium partner Advanced Energy Corporation (AEC) reproduced the phenomenon of solar driven moisture in the laboratory. AEC constructed a mockup of a roof assembly with the insulation installed directly under the roof sheathing. An array of lights provided the solar heating. Wetting of the shingles followed by heating increased moisture in the insulated cavity. Turning off the heat lamps led to rapid cooling (the testing facility is air- conditioned) and condensation. AEC’s roof mockup is shown in Figure 2a – 2d.

Figure 2a (above left): Roof with shingles; Figure 2b (above right): Roof with solar array

Figure 2c (above left): Roof wetting; Figure 2d (above right): Roof insulation

Figures 3a-3c illustrate the phenomenon of intermittent bucking of shingles due to solar driven moisture. This phenomenon occurs regardless of whether the roof is vented or unvented in the absence of a vapor barrier between the asphalt shingles and the roof deck. As the OSB or plywood roof sheathing absorbs moisture, the sheathing expands and decreases the space between adjacent sheets. This causes the roofing paper and shingles to buckle. Continued solar heating gradually drives moisture out of the sheathing and the buckling disappears. Since dew can provide enough moisture to create shingle buckling, the process is repeated daily at certain times of the year.

An impermable roofing underlayment will control the transmission of moisture through the roof assembly eliminating both the shingle buckling and the moisture drive into the roof deck. Many products can be used as this vapor barrier. Self-adherent waterproof roofing membranes have proven effective under a wide variety of roofing materials. BSC has identified a low permeability roofing “paper” that decreases the migration of moisture through the unvented roof assembly (see http://www.flexia.ca). This product is cost competitive with standard roofing underlayment but has a permeance of only 0.56 perms (dry cup method). Since this product is hydrophobic, its permeance will not increase when exposed to high moisture loads.

Final Note

There are additional important considerations and construction details when using unvented attics in hot-humid climates. For more information, see "RR-0411: Vent on Venting".

Footnote

- The phenomenon described here for a roofing assembly is similar to the physics of what can happen in certain brick veneer wall assemblies—see RR-0104: Solar Driven Moisture in Brick Veneer.