The Passivhaus (PH) standard is a set of voluntary criteria for an ultra-low energy use home. Originally developed in Germany for houses and low-rise multi-unit residential buildings, the standard has been applied to houses in a range of other countries and to commercial buildings as well. The most interesting aspect of the criteria of the Passivhaus standard may be that it has relatively few mandatory requirements, thereby providing design flexibility, and that it focuses exclusively on energy consumption. There are, however, many recommendations in the PH program that are not likely good decisions for cold climate (DOE Climate Zones 5-7) North American housing, and some are very impractical with little or no benefit to the environment or the homeowner.

Passive House in Darmstadt, Kranichstein — South elevation (left)

and interior (right)

(From http://www.passiv.de/)

The unique focus of the PH standard is an exceptional concern for heat loss by conduction and air leakage through the building enclosure and a complete disregard for the climate zone in its recommendations. High insulation values, very high performance windows, and airtightness levels better than any other building program anywhere are the normal result. Very efficient appliances are also practically required to meet the energy consumption targets.

Despite their name, homes built to the Passivhaus standard are not “passive.” All Passivhauses must have an active mechanical ventilation system and all have some type of active heating system, albeit very small ones. The use of passive solar design principles is recommended but not mandatory.

The Passivhaus concept was developed by Dr Wolfgang Feist and Prof. Bo Adamson in the late 80’s and implemented in research in the 1990’s. According to Feist, the inspiration of the PH program was the housing of William Shurcliff (a solar house pioneer) and Harold Orr (a superinsulated house pioneer of Saskatchewan House).

Requirements

The primary Passivhaus target criteria are:

a total heating & cooling demand of 15 kWh/m2/yr (4.7 kBtu/ft2/yr)

total primary (i.e., source) energy of 120 kWh/m2/yr (38 kBtu/ft2/yr)

airtightness 0.6 ACH@50 Pa or less

Even some of these requirements may not be actually be mandatory: in a 2008 interview in Energy Design Update1 Feist himself stated that the heating demand number could be anything. In this interview Feist also stated “As long as you build a house in a way that you can use the ventilation system … to provide heating and cooling it can be considered a Passivhaus.” By this latter definition, thousands of Building America homes that use the heating and cooling system to provide ventilation, are Passiv Hauses! Of course, if the requirement is for a non-recirculating heating system then this is quite restrictive and not very beneficial for cold climate housing.

Other commonly recommended (or, depending on what you read, required) measures include:

peak heating demand should be under 10 W/m2 (3.2 Btu/ft2)

total site energy of 42 kWh/m2/yr (13.3 kBtu/ ft2/yr)

window U-values of 0.8 W/m2K (0.15 Btu/ ft2/F, R-7.1)

high-efficiency heat recovery (over 80%)

The floor area is measured by total conditioned area inside the cladding. (The PHPP 2007 states on page 37, that “The dimensions used in the PHPP are always exterior dimensions. Therefore the most exterior layer of the thermal envelope are to be entered.” However, the area is reduced further by about 20% because stairwells, and walls are subtracted, as this is the standard German method of area calculation). The basement is only considered at 60% of its actual area because it is not considered living space in the German standards. Why, I can't understand; perhaps Germans don't build basements you can live in like a modern basement in North America.

Typical Passivhaus Approach

The typical Passive House approach is focused almost exclusively on the reduction of space heating loads, leaving the lighting, hotwater, cooling, appliance and misc. electrical loads to fall under the “total primary” requirement. However, it is widely acknowledged that very efficient appliances and lighting must be used to meet the primary/source energy targets in most cases.

Almost all Passivhauses rely on:

very heavy insulation, R-40 to R-60 walls, R-50 to R-90 roofs, and often R-30 to 50 sub-slab insulation, triple-glazed low-e windows, and exceptional avoidance of thermal bridges (except for wood framing)

- ultra-airtight construction (0.6 ACH@50) which, together with the R-value requirements, usually result in designers needing to choose simpler shapes

- passive solar gain for a portion of the heating by orienting the house to the south and using a window SHGC of around 0.5 (or higher if possible),

- heat recovery, in the past with earth tubes and more recently with dual core HRVs to reach high 80% to low 90s efficiency, but essentially always with supply air to each space with return air pathways, and

- heating of the ventilation air to provide space heating, although many homes use radiant floors, walls, ceilings, and radiators.

The diversity of solutions is, however, large, and could be considered a strength of the program. There are Passivhauses that use gas boilers to provide heating, and those that include solar hotwater and/or PV, and wood stoves. Cooling on the other hand, is rare, largely because of the geographic areas in which the program has been more widely adopted.

Insulation and Airtightness

Insulation levels of walls of Passivhaus’s are generally in the range of R-40 to R-60 for walls, R-60 to R-90 for roofs, and R-30 to 50 for slabs. Perhaps just as importantly, thermal bridges are rather accurately accounted for in the calculation methodology.

Window specifications are also demanding. A common specification is for U=0.15 (0.8 W/m2 K) or less for windows. It is not clear how to translate these values to North America, as the NFRC testing methods generally result in about a 10% increase in heat flow for the same window as compared to European standards. However, to approach these targets windows certainly need to have non-conductive frames (vinyl, wood or fiberglass) and triple-glazing, low-e coatings and gas. In fact, it is very difficult to find commercially-available operable windows that can achieve these specifications, and imported PH-certified windows reportedly cost about twice as much ($90-100 per square foot) as much more readily available triple-glazed fiberglass windows (R6 at $50/sf).

The airtightness level of 0.6 ACH@50 is also extraordinary. It is achieved in North America by very few homes, and always when built as special custom houses, usually with a very simple plan form and simple roof lines. One Swedish prefabricated house exporter2 states that it does not recommend Passivhaus standards for any of its house plans other than single-storey ranches because of its experience with the difficulty of reliably meeting the stringent airtightness target with other than the simplest of building shapes.

Ventilation and Heating

Although it is recommended that the peak heating demand be kept to under 10 W/m2 (3.2 Btu/ft2) this is not mandatory and is based on the desire to heat the house with ventilation air only. However, based on our analysis at BSC, this recommendation is both very difficult to achieve in cold climates (using standard calculation methods), and unnecessary for achieving low annual energy consumption. By using extreme insulation and eliminating safety factors such as thermal mass and internal gains it is possible to reach this low of a heat demand.

In Europe, higher ventilation rates are often specified, likely because there is not a long history of providing mechanical ventilation, and past systems did not distribute air to each room. The 2007 Passive House Planning Package (PHPP 2007) recommendation is 30 m3/hr, which is 17.5 cfm/person, whereas ASHRAE 62.2 requires 7.5 cfm/person+0.01 cfm/ft2. The PHPP 2007 also states that the “average air change rate should not fall below 0.3 ACH.” For a 3-bedroom 2000 square foot single family home, this results in a PH ventilation rate of 80 cfm versus 50 cfm (25 l/s) for ASHRAE 62.2-2007. Although this 60% difference is not too large, so many PH have been ventilated at much higher rates that the PHPP 2007 (page 81, section 14.1) warns users not to over-ventilate.

The PHPP 2007 also sets the maximum temperature of air delivery be less than 52 °C (126 °F). This limits the heat delivery rate to about 60 Btu/hr per cfm of airflow (126 supply less 70 F return times 1.08 Btu/hr/cfm/F = 60). If the 50 cfm of ventilation air from the 2000 ft2 home were heated to the maximum of 126 °F (52 °C), it could deliver a maximum total of 3000 Btu/hr, or about 15 times less heat than a standard small furnace! This works out to a heat delivery of just 1.4 Btu/ft2 (4.3 W/m2). To deliver the PH maximum heating intensity of 10 W/m2 (3.2 Btu/ft2) with ventilation air would require a ventilation rate of 115 cfm (60 l/s), which is 2.3 times the ventilation rate of ASHRAE 62!

If one were to apply such an approach, the over-ventilation would impose a very significant energy penalty for a low-energy house as it is tantamount to using a mechanical system to impose air leakage. It is likely for this reason that the Passivhaus Institut recommends very high efficiency (eg 75-85%) heat recovery ventilators with high efficiency fans. Although the standards for measuring HRV efficiency in Europe are different than North America, it should be clear that a standard 65% efficiency HRV (a typical specification in North America) operating at 50 cfm and 0.6 W/cfm, will use less energy than a very expensive 75% efficient HRV operating at 80 cfm and 0.75 W/cfm.

Hence, North American houses ventilated to ASHRAE 62.2 with a standard efficiency (>60%) HRV and efficient fan motors (>1.5 cfm/W) will consume less energy than most Passivhaus-approved ventilation systems. Such HRV/ERV units have been installed in numerous Building America, Energy Star, R2000, and just better homes. The energy savings of an HRV relative to a central fan-integrated ventilation system (i.e. FanCyclers) are small, but for very low-energy buildings in cold climates, an HRV with the specification recommended above can usually reduce primary energy consumption.

It should be noted that many North American HRV’s consume excessive amounts of electrical energy and should be avoided. Energy Star will soon be limiting the electrical energy draw of HRVs but these requirements will not come into force for several years. Numerous right-sized HRV’s (meeting ASHRAE 62.2) with efficient fans (i.e., 0.5 to 0.75 W/ cfm) are available and can be purchased for $500 to 700. In more moderate climates, central fan-integrated ventilation systems (i.e., without heat recovery) consume only very little additional energy than a high performance HRV, but provide equivalent quality ventilation at a fraction of the capital cost.

Given the standard rates of ventilation and the occurrence of design temperatures of 0 °F (-18 °C) or lower in parts of the United States and Canada, increasing ventilation rates to allow the use of ventilation air as the only means of heating is at best highly restrictive to a design and at worst simply impractical and antithetical to a low-energy house.

There also appears to be an almost dogmatic avoidance of using radiant floors or air-based heating with re-circulating airflows (the two most commonly available heating systems in most parts of North America).

Although radiant floors provide “too much” heat in a low energy house, they may be desirable from a comfort perspective, particularly if they are applied to small areas of the home (e.g. under tiled floors in bathrooms and kitchens). That said, radiant floors are rarely the lowest cost approach to space heating.

One of the Passivhaus recommendations is that duct air velocity be kept below 3 m/s (588 fpm). In all of our projects, BSC recommends trunk velocities should be kept between 500 and 750 feet per minute and runout / branch duct velocity should be under 500 fpm. These limits save fan energy and reduce noise.

Another recommendation common to both Passive Houses and BSC Building America houses is the requirement for defined return air pathways, and the specification of transfer grilles. PassivHaus describes a target pressure drop of 1 Pa, whereas BSC allows up to a 3 Pa pressure drop across grilles. The Passivhaus standard makes no mention of ducts outside the enclosure as this risky practice is almost unknown in Europe.

Typical BSC BA low-energy house

Numerous BSC-designed Building America prototype homes have been built in cold climates (Zone 5 and higher) that compare well to the Passivhaus standard in terms of their primary/source energy consumption. That is, they consume perhaps 40 to 60% more than a Passiv Haus, but are more cost-effective. Typically, these houses use a minimum of R-5 (U=0.2) windows (triple-glazed, low-e coated, warm edge spacers), R-10 sub-slab insulation and R-20 wall insulation in a conditioned basement, R-40 above-grade walls and R-60 ceilings (the "5/10/20/40/60" approach). All thermal bridges in these BSC houses are controlled by using insulation on the exterior of the framing. These R-values are comparable, if on the low-end, of the range that PH use.

Airtightness levels of 3 ACH@50 Pa can regularly be achieved by production builders if airtightness details are tested, and some training and airtightness testing is undertaken. In our experience, and that of others, airtightness levels of 1.5 ACH@50 Pa can be reliably achieved if significant effort is taken in designing details for airtightness, and on-going training, testing, and inspection is employed. In the experience of the Building America and the Canadian R2000 program, such airtightness levels are achievable, but with some effort. The biggest obstacle to achieving lower air leakage may be complexity in building shape. Given the state of practice of air barriers and trade skills, the 0.6 ACH@50 level demanded by PH is too difficult to achieve for production homes (although achievable in custom homes), and hard to justify in any case given the small incremental benefit to energy, air quality or durability.

The BA program expends a significant amount of effort to ensure that a BA house is more durable and healthier than equivalent housing. There is essentially no discussion of durability and little on IAQ in the PH standard: the effect on the durability of exterior building materials when the insulation levels rise to the levels used is not discussed, nor is the need for heightened rain control requirements, although damaging air leakage condensation is likely controlled by the very low acceptable air leakage.

Energy Consumption Compared

Measurements (not the Building America Benchmark assumptions) show that electricity use for appliances and miscellaneous loads can be held to 3000-4000 kWh/year per household in a modest sized, typical home. This can be reduced further by very efficient appliances, exceptional lighting, and by better controls. The reported values for Passivhauses tend to be lower, in the range of 2500 to 3000 kWh/year. These lower levels can be achieved in North American homes, but depend on occupants operating and maintaining the home in a low energy manner.

Domestic hotwater energy consumption is approximately 3000 - 4000 kWh/year per household in American homes.3 Large variations depend on the lifestyle of the occupants, but this energy use appears to be similar in Passivhauses. If a basement is available, this energy use can be reduced (perhaps by 10-20%) by drainwater heat recovery and reduced (perhaps by 10-20%) by choosing the very lowest hot water use appliances. Again, occupant behavior is critical: a retired couple may use half this energy, whereas a family of five with teenage children can use 50% more. A reasonably priced two-panel flat-plate solar hot water system can provide about 2000 kWh/yr of preheated water to the domestic hot water appliances even in cold climates.

Space conditioning and ventilation energy demand for houses built to the low energy standard described above in DOE Climate Zones 5-7 tends to be 10000 to 15000 kWhe for a house with 2000 ft2 living space (54 to 80 kWhe/m2/yr). An upgrade from double to triple-glazed windows (R-3.3 to R-5 or R-6), and the addition of an efficient HRV drops these values by 2000-3000 kWh/yr, and if a south-facing exposed solar lot is available, another 1000-2000 kWh can be reduced. Hence space heating energy values can be reduced to the range of 7000-11000 kWh/yr by some combination of measures that may be available on some lots (full south exposure is often NOT available) and may be cost effective in some situtations (triple-glazed windows are not always cost effective).

Using a site-to-source (site-to-primary energy to use PH terms) conversion of natural gas to electricity of 3 (which is about mid-way between the German 2.7 value and the US Department of Energy gives as a 3.365 value), the following general energy use profile can be developed for a 25 by 40 ft raised ranch home with a fully finished basement (e.g., a home with 2000 ft2 of conditioned, useable space).

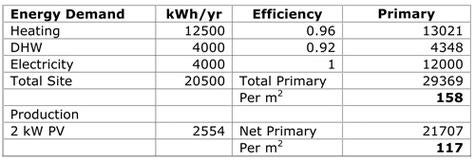

The table below takes mid-range values for energy consumption and converts this energy demand to primary (source) energy use. It assumes the smallest available standard condensing natural gas two-stage furnace with an ECM motor (e.g. Goodman GMH95), a condensing sealed-combustion hotwater heater (such as an AO Smith Vertex, Navien, Quietside, or Viessman VitoDens), an efficient HRV (such as a Fantech VHR704 with an AirCycler controller), Energy Star appliances and all CFL lighting.

Table 1: Energy Consumption for a Typical Low-Energy BSC Building America

prototype home

As can be seen, the source energy consumption, at 158 kWh/m2/yr, exceeds the Passivhaus requirement of 120 kWh/m2/yr (because the German method of floor area calculation is different than that used in North America, the whole house comparison is more accurately 29300 vs 17800 kWh). However, for a further unsubsidized investment of under $20000, a 2.5 kW PV array (which can generate 3250 kWh/yr) can be installed that reduces primary energy consumption by 9750 kWh to close in on the arbitrary (and laudable) Passivhaus energy target. The PV was chosen in this case as it was the least cost approach to achieving the target. In many cases triple-glazed windows and ERV (at an upcharge of $4000-5000 these measures may save 2000-3000 kWh/yr) may be a less expensive approach in conjunction with a 2.0 kW array. PV is currently the most expensive un-subsidized form or renewable energy, often at a cost of 50 to 70 cents per kWh. Many renewable and/or no-carbon sources of electricity (such as wind, bio-mass, tidal, etc) can be produced for 1/2 to 1/3 this cost (see also BSI-026: Passivhaus Gets Active).

Some of the PH recommendations require designers to spend more limited resources on conservation that are even more expensive that producing the energy at the very high bar of current PV prices. For example, in a 6000 HDD F climate, switching from a 0.6 W/cfm, 63% efficient Fantech HRV to a PH-certified 80% efficient, 0.75 W/cfm HRV will, even if one uses the same ASHRAE 62.2 50 cfm ventilation rate, saves $11 per year in heating energy at $1.65/therm gas and 15 cent/kWh prices. Even if gas and electric prices triple in the next ten years, it is not feasible that the $1000-$1200 premium commanded by a PH-certified HRV can ever be recouped. Upgrading the 200 square feet (10% of floor area served) of R6 windows (such as Inline fiberglass with argon-filled dual low-e coatings) to R-7.1 PH-certified windows (superior performance) might save 250-400 kWh/yr in a 6000 HDD climate, but would command a $10000 premium at current prices. Increasing the R-value of sub-slab insulation from R-20 to R-40 is another measure that is very expensive.

Doubling the insulation levels of the proposed home (i.e., changing the specs to R-10 windows, R-80 walls, R-120 roof, 0.6 ACH@50, and a 100% HRV),) and increasing airtightness would not necessarily reduce primary energy demand enough to meet the PH energy target. Increasing the insulation, window, and airtightness values to these levels is not only quite expensive, but very architecturally constraining, i.e., dormers, bay windows, etc all become challenging to incorporate and maintain low surface-volume ratios. Even with all of the measures to halve the heating energy demand, the primary energy demand intensity would barely drop below 120 kWhe/m2/yr (the PH energy target).

In DOE Climate Zone 6 or 7, the peak heating demand of the extreme R-10/R-80/R-120 specification would remain above the 10W/m2 (3.2 Btu/ft2 or 6400 Btu/hr) PH recommendation without relying on occupant producing average heat (eg not below average, with one person at home) and thermal mass, and 50 cfm of ventilation airflow would not be sufficient to provide space heating on a design 0 °F or -10 °F night (that is, the heat loss would need to be lowered to 3000 Btu/hr for ventilation air to provide heating). As the cost of an efficient furnace (described above) is less than about $2500 installed (plus ductwork, which is largely needed for ventilation anyway), and smaller capacity furnaces cost no less, there are essentially no capital cost savings to reducing space heating energy demands.4

From a point of view of the wise use of capital, the Passivhaus approach in cold-climate zones of North America can lead to more expensive, less architecturally flexible, and even potentially more energy intensive houses than a more flexible approach that focuses only on the least cost, most durable means of achieving a primary energy use per area target value. Perhaps the most important contribution made by the PH standard to low-energy North American housing is that one cannot simply buy $200,000 worth of PV panels to meet the target, as too many net zero homes have done.

Conclusions

Homes in cold climates (DOE Zones 5-7) that employ:

minimum R-5:10:20:40:60 enclosure,

1.5 ACH@50 airtightness or better,

condensing (>95%) gas furnaces with ECM fan motors,

right-sized (ASHRAE 62.2) efficient (> 65%, >0.6 W/cfm) HRV’s

condensing (>92%) hotwater natural gas water heaters

appliances in the top 10% of Energy Star combined with CFL lighting

deliver total energy and environmental performance that approaches the Passivhaus standard in cold climates. Such houses depart in relatively minor ways from standard North American construction, accommodate a broader range of architectural styles, can be modified easily for different climate zones, and can even be built by production builders.

Achieving the specific Passivhaus target of 15 kWh/m2/yr for heating on site energy use, results in investment of materials and money that often will exceed other less costly and environmentally impactive solutions. Achieving the equally arbitrary 120 kWh/m2/yr has more direct environmental benefits than the heating target, but may best (i.e., with least cost and environmental damage) be achieved using some on-site or renewable off-site power generation.

As new clean, local, and renewable energy sources come on line over the next 25 years and become more affordable than current PV prices, it is unlikely that the extreme conservation measures taken by Passiv Haus to meet the specific requirements will be considered an optimal deployment of resources for cold climate housing.

References

“An Interview with Wolfgang Feist”, Energy Design Update, Aspen Publishers, Vol 28, No. 1, January 2008.

Passive House Planning Package 2007/1-E, Passivhaus Institut, Darmstadt Germany, 2007.

“Certification as Quality Approved Passive House: Criteria for Residential-Use Passive Houses”, June 18, 2007, Passivhas Dienstleistung GmbH.

The best source of information is the official website of the Passiv Haus Institut, www.passiv.de and www.Passivhaus-info.de.

Footnotes:

Energy Design Update. “An Interview with Wolfgang Feist” Aspen Publishers, Vol. 28, No. 1, January 2008.

Scandinavian House accessed from www.scanhome.ie 2009.0717

kWh is used as the unit of energy in this article. One kWh = 3412 Btu. One therm of gas = 29.3 kWh.

European quality boiler heating systems are quite different as the typical cost is over $20,000 installed, and thus avoiding their use is a major capital cost saving.