On System Charging, Superheat and Subcooling

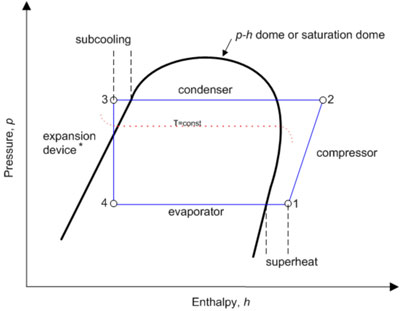

Check charge on fixed orifice metering systems (piston or capillary tube) by measuring superheat. Superheat degrees are figured by taking the difference between the suction saturation temperature and the suction line temperature at the condenser. If the specified target superheat is less than 5 °F then you can't determine if the system is under- or over-charged. Leave it alone. If the target superheat is greater than 5 °F, then you should try get it to be within 2 °F of the target.

Check charge on thermal expansion valve (TXV) metering systems by measuring subcooling. Subcooling degrees are figured by taking the difference between the discharge saturation temperature and the discharge line temperature. The amount of subcooling for optimum operation should be specified by the equipment manufacturer.

An overcharged system will have low superheat, potentially allowing liquid refrigerant to damage the compressor. Too much refrigerant passes through the evaporator too quickly so that not all of the liquid-vapor refrigerant mixture becomes saturated vapor then superheated vapor. Liquid refrigerant returning to the compressor can cause premature failure. Removing refrigerant increases leaving evaporator superheat by reducing system pressure and slowing the flow of refrigerant through the evaporator. The suction line saturation temperature will go down and the spread between suction saturation temperature and suction line temperature will increase.

An overcharged system tends to have high subcooling. The elevated compressor head pressure and temperature can cause overheating and premature failure.

An undercharged system will have high superheat (see icing exception*). Too little refrigerant passes through the evaporator too slowly so that all of the liquid-vapor mixture becomes saturated vapor then superheated too soon. Capacity and efficiency is reduced because of the lower mass of working fluid (refrigerant) and because the compressor suction stroke is less efficient. Adding refrigerant decreases leaving evaporator superheat by increasing system pressure and increasing the flow of refrigerant through the evaporator. The suction line saturation temperature will go up and the spread between suction saturation temperature and suction line temperature will decrease.

An undercharged system will also have low subcooling. Vapor bubbles in the liquid line will impede the ability of the liquid metering device to properly meter refrigerant, and the metering process will be noisier.

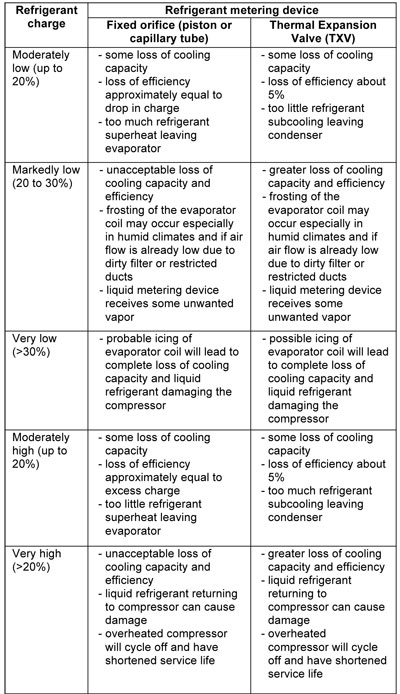

Figure 1: Symptoms and results of improper refrigerant charge for fixed and variable metering devices

Figure 2: Vapor compression system Pressure vs. Enthalpy

Footnote

* Icing tends to begin from a corner or side of the evaporator coil where refrigerant is first distributed and where air flow may be lowest due to air flow patterns in the air handler. As icing creeps across the coil, air flow becomes more restricted, further lowering the coil temperature and hastening the icing process. If the coil ices over, severely restricting or stopping air flow, then air to refrigerant heat transfer ceases and the refrigerant returns to the compressor as a liquid-vapor mixture without becoming saturated vapor or superheated vapor.