Ductwork, furnaces and air handlers should be sealed against air leakage. The only place air should be able to leave the supply duct system and the furnace or air handling unit is at the supply registers. The only place air should be able to enter the return duct system and the furnace or air handling unit is at the return grilles. A forced air system should be able to be pressure tested the way a plumber pressure tests a plumbing system for leaks. Builders don’t accept leaky plumbing systems, so they should not accept leaky duct systems.

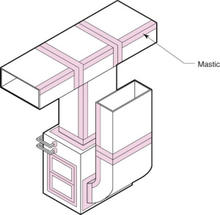

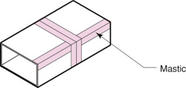

Supply systems should be sealed with mastic in order to be airtight. All openings (except supply registers), penetrations, holes and cracks should be sealed with mastic or fiberglass mesh and mastic. Fabric/rubber duct tape (common duck tape developed for temporary repair of cotton duck tarps and raingear has thousands of uses; sealing ducts is not one of them) should not be used: after hot and cold cycling, the adhesive dries out and fails. Tapes meeting UL 181A or 181B may provide reasonable performance. These must be applied only to clean, dry, and dust-free surfaces. Sealing of the supply system includes sealing the supply plenum, its attachment to the air handler or furnace, and the air handler or furnace itself. Joints, seams and openings on the air handler, furnace or ductwork near the air handler or furnace should be sealed with both fiberglass mesh and mastic due to greater local vibration and flexure.

Return systems should be “hard” ducted and sealed with mastic in order to be airtight. Building cavities should never be used as return ducts. Stud bays or cavities should not be used for returns. Panned floor joists should not be used. Panning floor joists and using stud cavities as returns leads to leaky returns and the creation of negative pressure fields within interstitial spaces. Carpet dustmarking at baseboards, odor problems, mold problems and pollutant transport problems typically occur when building cavities are used as return ducts.

The longitudinal seams and transverse joints in sheet metal ducts should be sealed. The inner liner of insulated plastic flex duct should be sealed where flex ducts are connected to other ducts, plenums, junction boxes and boots/registers.

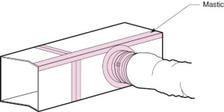

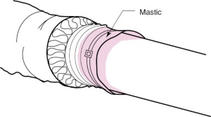

The recommended procedure to connect insulated flex duct to a metal collar is as follows:

- brush a thick coat of mastic around the collar;

- slide the inner liner over the collar;

- tie wrap the collar with a tensioning tool (not just by hand);

- pull the outside liner over the boot;

- tape the outside liner to the boot with appropriate tape;

- brush mastic over the tape bridging from the outside liner vapor barrier to the vapor barrier of the boot.

When flex ducts are used, care must be taken to prevent air flow restriction such as those resulting from "pinching" ducts or from kinks caused by bending them at a tight radius.

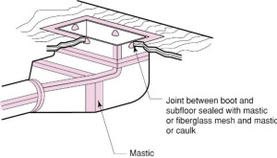

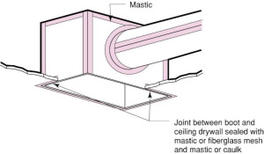

Connections between grilles, registers and ducts at ceilings, floors or knee walls typically leak where the boot does not seal tightly to the grille or gypsum board. Air from the attic, basement, or crawlspace can leak in or out where the ducts connect to the boot.

If the gap between boots and gypsum board opening or subfloor openings is kept to less than 3/8-inch, a bead of sealant or mastic may be used to seal the gap. Where gaps are larger than 3/8-inch, fabric and mastic should both be used. The optimum approach is to keep the gaps to less than 3/8-inch and use a bead of sealant. This requires careful coordination with the drywall contractor to make sure that the rough openings for the boots are cut no more than 3/8-inch bigger than the actual boot size on all sides.

Air Sealing Details

| |||

Photograph 1: Retrofit Sealing of Air Handler and Plenum