This article addresses the issue of unsealed wall stud cavities or panned floor joists used as a return air plenum resulting in risks such as indoor air quality issues due to negatively pressurized cavities drawing air through cracks along with any contaminants and also condensation by drawing in warm humid air. Corrective measures are also suggested.

Unsealed wall cavities used as return air plenum

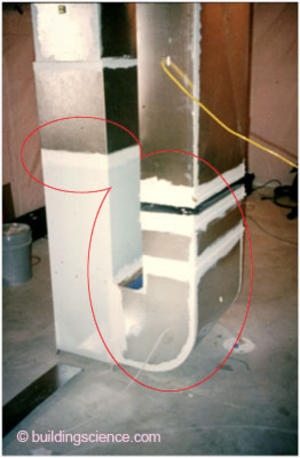

Air sealed furnace (left); air sealed return plenum (right)

Issue

Unsealed wall stud cavities or panned floor joists as a return air plenum.

Description of Implementation Error

Building cavities are not practical to seal, and therefore remain unsealed, but they are used instead of conventional ductwork to return air from the conditioned space to the conditioning equipment whether it is from a furnace or air conditioner.

Risks

The practice of using unsealed building cavities as ductwork may result in indoor air quality issues. The negatively pressurized cavities will draw air through any cracks to try to alleviate the pressure difference. This means that the return system will suck on the walls—and any contaminants that might be in the walls—and redistribute them to the living space. By negatively pressuring the walls in a hot-humid climate, warm humid air could be drawn into the walls from the exterior, and condensation is likely to occur on the cooler air-conditioned surfaces.

Required Corrections

Only fully-ducted and sealed returns should be used but it is also important that the air conditioning equipment should also be sealed, especially when located in a vented crawlspace or attic. Air sealing should ideally be done with mastic, or (second choice) tape meeting UL 181A or 181B.1 Pressure testing of the entire ducting system and conditioning equipment will determine the amount and location of air leakage with a fan and manometer.

Footnote