This overview summarizes non-combustible steel framing using mineral fiber insulation board including the advantages and disadvantages of this construction strategy. Complex two dimensional heat flow analysis and one-dimensional hygrothermal modeling were used to determine moisture related durability risks for analysis.

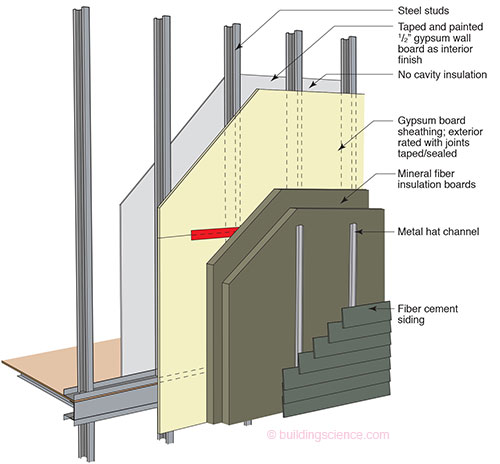

- Fiber cement siding

- Metal hat channel creating a minimum 3/8" ventilation gap/drainage gap behind cladding

- Two 2" mineral fiber insulation boards

- Gypsum board sheathing

- 6" metal studs with no cavity insulation

- Interior gypsum wall board

Thermal Control

Installed insulation R-value: This wall construction does not contain any cavity insulation.

Mineral fiber used as the exterior insulation has an R-value of 3.8-4.3/inch resulting in an installed insulation R-value between R-15 and R-17 for 4” of mineral fiber insulation board.

Whole-wall R-value: Two-dimensional heat flow analysis of advanced framing steel stud walls with no cavity insulation and 4” of mineral fiber insulation board on the exterior have a whole wall R-value between R-15 to R- 17.

Air Leakage Control: Mineral fiber insulation board is not air impermeable (unlike EPS, XPS and foil-faced polyisocyanurate board foam). Air control is established at the face of the exterior gypsum board sheathing with taped seams.

Typical insulation: Mineral fiber insulation boards are used as the exterior insulation.

Durability

Rain Control: Rain leakage into the enclosure is the leading cause of premature building enclosure failure. The mineral fiber insulation board, although hygrophobic, is not suitable for creating a water control layer at the surface of the insulation as may be done with foil-faced polyisocyanurate or extruded polystyrene (XPS) insulation boards. Rain control is addressed using the exterior gypsum board with taped seams.1

Air Leakage Control: Air leakage condensation is the second largest cause of premature building enclosure failure with this type of wall construction. It is very important to control air leakage to minimize air leakage condensation durability issues. Using mineral fiber insulation board decreases the risk of air leakage condensation by increasing the temperature of the condensation plane, but condensation is still possible in cold climates as mineral fiber insulation is not an air barrier material. An air barrier is required in this wall system to ensure that through-wall air leakage is eliminated (ideally) or at least minimized.2 An air barrier should be stiff and strong enough to resist wind forces, continuous, durable, and air impermeable. Air control is established at the face of the exterior gypsum board with taped seams that is detailed to serve as both a water control and an air control layer.3

Vapor Control: Wintertime condensation caused by outward vapor drive is controlled in the wall assembly by insulating to the exterior of the exterior gypsum board. The wall assembly manages summertime inward vapor drive through a vented cladding. It can be supplemented by installing a fluid applied vapor retarder on the exterior of the gypsum board. Such layers are typically marketed as fluid applied air barriers. Select one with an appropriate vapor transmission. The recommended vapor transmission of this layer is between 5 and 10 perms. A low perm housewrap installed at this location (on the exterior side of the gypsum board) can also serve this function.4

Drying: Mineral fiber insulation board allows drying to the exterior. Additionally, the wall also is able to dry to the interior. Poly vapor barriers should be avoided so that inward drying can occur. The minimum level of vapor control on the interior surface is determined by the IRC. In this “flow through assembly”, the prescriptive portion of the IRC relating to vapor control allowing omission of a poly vapor barrier is met by installing sufficient mineral fiber insulation on the exterior. Installing a vapor barrier on both sides of the enclosure will seal any moisture into the stud space, resulting in low drying potential, and possibly resulting in moisture-related durability risks. Ventilation behind vapor impermeable claddings and interior components (e.g. kitchen cabinets) can encourage drying.

Built-in Moisture: Care should be taken to build with dry materials where possible, and allow drying of wet materials before close in.

Durability Summary: The primary durability risks associated with these wall assemblies involve moisture damage related to rain water penetration and air leakage condensation. Both air and water control are established at the face of exterior gypsum board with taped teams.

Buildability

Exterior insulation up to 11/2” requires minimal changes to standard enclosure construction practices. Exterior insulation in excess of 11/2” requires changes to window and wall construction and detailing which requires training and monitoring during the initial implementation.

Cladding can be easily attached to the studs through 1” of exterior insulation. Thicker levels of insulation (>2”) require strapping or furring strips anchored to the framing with long fasteners. Some cladding manufacturers allow their cladding to be fastened to the strapping directly.

Cost

Cost of mineral fiber insulation increases with its thickness. Also, with insulation board thicknesses over 11/2”, furring strips would be required for cladding attachment which add to the cost. But there are measurable cost benefits of saving energy, as well as improvements to comfort, which is difficult to quantify.

Material Use

With mineral fiber insulation board thicknesses over 11/2”, furring strips would be required for cladding attachment.

Summary

This is highly insulated non-combustible wall system that will work in extreme climates as part of a high-R enclosure.

References

- Lstiburek, J. W. (2006). Water Management Guide.

- Lstiburek, J. (2008, 08 20). BSD-104: Understanding Air Barriers.

- Straube, J. (2009, 04 22). BSD-014 Air Flow Control in Buildings.

- Lstiburek, J. (2008, 10 17). BSD-106 Understanding Vapor Barriers.