This project examines the implementation of an exterior insulation and over-clad strategy for brick masonry buildings in Chicago. The strategy was implemented at a free-standing two story two-family dwelling and a larger free-standing multifamily building. The test homes selected for this research represent predominant housing types for the Chicago area. The retrofit measures are evaluated in terms of feasibility, cost and performance. Through observations of the strategies implemented, the research described in this report identifies measures critical to performance as well as conditions for wider adoption. The research also identifies common factors that must be considered in determining whether the exterior insulation and over-clad strategy is appropriate for the building.

Executive Summary

This project examines the implementation of an exterior insulation and over-clad strategy for brick masonry buildings in Chicago. The strategy was implemented at a free-standing, two-story, two-family dwelling and a larger free-standing multifamily building. The test homes selected for this research represent predominant housing types for the Chicago area. High heating energy use typical in these buildings threatens housing affordability. Uninsulated mass masonry wall assemblies also have a strongly detrimental impact on comfort. It will be necessary to significantly change the performance of the wall if these masonry buildings are to be elevated to a level of performance on par with current standards.

Significant changes to the performance of masonry wall assemblies is generally beyond the reach of typical weatherization (Wx) program resources. Community and Economic Development Association of Cook County, Incorporated (CEDA) has secured a Sustainable Energy Resources for Consumers (SERC) innovation grant sponsored by the U.S. Department of Energy (DOE). This grant provides CEDA the opportunity to pursue a pilot implementation of innovative approaches to retrofit in masonry wall enclosures. This research project evaluates the implementation of an exterior insulation and over-cladding approach at two masonry buildings representing predominant types within the Chicago-area housing stock. The retrofit measures are evaluated in terms of feasibility, cost, and performance.

The exterior insulation and over-clad strategy was designed to allow implementation by contractors active in CEDA Wx programs and using materials and methods familiar to these contractors.

The research identifies:

- Conditions under which exterior insulation and over-clad of masonry walls is recommended

- Significant implementation challenges to exterior insulation and over-clad of masonry walls

- Levels of airflow control that can be achieved with the strategy

- Risks inherent in the approach that must be addressed

- Measures and practices critical to achieving performance in exterior insulation and over- clad of masonry walls

- Successful strategies to integrate windows into masonry wall exterior insulation and over-cladding systems.

Through observations of the strategies implemented, the research described in this report identifies measures critical to performance as well as conditions for wider adoption. The research also identifies common factors that must be considered in determining whether the exterior insulation and over-cladding strategy is appropriate for the building.

1 Problem Statement

The predominant construction types for residential structures—single-family detached as well as multifamily—in Chicago involve load-bearing masonry walls. Methods to insulate these wall assemblies are typically beyond the reach of Wx programs. Yet, the need for improved thermal performance in these masonry buildings is clear. Residential buildings in the Chicago area exhibit appreciably higher heating energy use than other types of construction and other cold climate regions of the country (AGA 2010). Energy costs are an increasing burden on household incomes. Uninsulated mass masonry wall assemblies with poor performing glazing also have a strongly detrimental impact on thermal comfort. It will be necessary to significantly change the performance of the wall thermal enclosure if these masonry buildings are to be elevated to a level of performance on par with minimum current code standards.

Adding insulation to the walls of such masonry buildings in cold, and particularly cold and wet, climates may cause performance and durability problems in some cases. The problems and solutions are outlined by practitioners such as Maurenbrecher et al. (1998), Gonçalves (2003), and Straube and Schumacher (2002, 2004).

Examples of concerns associated with interior insulation of mass masonry walls include freeze- thaw damage—due to reduced outward heat flow—and the decay of wood structural framing members (typically floor joists) that are embedded in mass assemblies—due to increased equilibrium moisture contents. The masonry freeze-thaw issue has been examined by (among others) Mensinga et al. (2010) and Straube et al. (2012). The embedded floor joist decay issue has been studied by some practitioners (Dumont et al. 2005; Morelli 2010; Ueno 2012), but many issues remain unresolved.

In addition to the risks associated with interior insulation of mass masonry, this strategy has limitations to performance in factors such as the common occurrence of integrated floor or wall assemblies representing thermal bridges. The amount of insulation that can be accommodated to the interior of a mass masonry wall without reconfiguring the interior space is typically limited to the depth of interior framing or strapping cavities and the performance of insulation materials that can be loose blown into these cavities.

When a building is occupied, the application of interior insulation strategies can be very disruptive to residents. Working around resident schedules and belongings also tends to significantly complicate the implementation. Adding insulation to the exteriors of existing buildings has been demonstrated to be an effective means to overcome these limitations and provide higher effective R-values for building wall assemblies. The benefits of this approach extend beyond just added thermal resistance; benefits of increased building durability and airtightness are often also realized (Ueno 2010).

The underlying concept of insulating the exterior of existing masonry walls has a variety of advantages for durability and air barrier continuity (Hutcheon 1964; Lstiburek 2007). Furthermore, exterior insulation retrofit can often achieve a greater amount of thermal resistance than is typically feasible with interior insulation retrofit. The practice should be simple; however, several problems stand in the way of widespread implementation. For example, manufacturers of cladding systems and exterior insulation materials often limit thicknesses to 1½ in. with their warranties; the cladding attachment is therefore an issue. This problem has been tackled by various researchers and practitioners (Straube and Smegal 2009; Pettit 2009; Joyce 2009; Ueno 2010; Baker 2012). Demonstrations by members of our research team have shown that up to 8 in. of exterior insulation over the exteriors of masonry and frame buildings is practical (Lstiburek 2009).

The lack of widespread recognition of attachment methods by manufacturers has resulted in obstacles for building official and building code acceptance. Additionally, the construction industry has not demonstrated familiarity with details for water management and integration of window systems, door systems, decks, balconies, and roof-wall intersections in assemblies with thick exterior insulation. Baker (2012) proposed an engineering basis and support for the installation of thick layers of exterior insulation on existing masonry and frame walls. His report also demonstrates water management details necessary to integrate windows, doors, decks, balconies, and roofs.

Long-term solutions to the energy cost burden and comfort problems of existing masonry construction buildings will require measures to improve the performance of the masonry wall assemblies. Widespread adoption of one possible solution, exterior insulation of masonry walls, will require demonstration projects that prove the feasibility of the techniques and evaluate challenges. Through the SERC innovation grant, CEDA has the opportunity to demonstrate and study such measures. Through a Building America partnership, Building Science Corporation (BSC) has partnered with CEDA to provide technical guidance for—and evaluation of—the retrofit measures implementation. In providing technical guidance toward water management details and cladding attachment, BSC drew on previous and concurrent research into exterior insulation retrofits.

2 Project Context

2.1 Chicago Masonry Buildings

Masonry buildings are the dominant residential building type in Chicago. While this may be expected for large older multifamily buildings, it is also true of smaller residential buildings in Chicago. According to Cook County Assessment Department data, 57% of one-unit housing stock and 58% of two-to four-unit housing stock in Cook County is of masonry construction.1

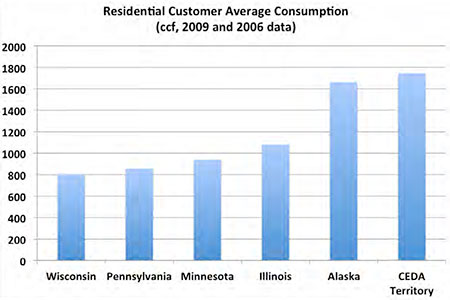

Compilation of utility data shows Illinois has the second-highest average gas consumption per residential customer for all the United States (AGA 2010). Only residential gas customers in Alaska use more, on average, than residential gas customers in Illinois (see Figure 1). Homes within the CEDA service territory are using even more on average than the rest of the state, surpassing the residential customer average for Alaska and using nearly twice the gas per household as other heating climate areas such as Minnesota.

Figure 1. Average gas consumption per residential customer for several cold climate states and the CEDA territory

2.2 CEDA Weatherization

The Multifamily portion of the Illinois Home Weatherization Assistance Program (IHWAP) is for building owners who provide housing to income-eligible residents in Chicago and suburban Cook County. The program is at no cost to the building owner, if 66% or more of the tenants are income eligible.

The CEDA Wx program serves income-eligible clients and includes households residing in multifamily buildings, in Cook County, Illinois. A multifamily building qualifies for services if at least two thirds of the households in a multifamily building are income eligible. CEDA Wx is one of more than 30 community action agencies that participate in IHWAP. The Illinois Department of Commerce and Economic Opportunity administers the program; its Office of Energy Assistance monitors all agencies in the IHWAP network. The services that CEDA Wx provides are structured around a comprehensive energy audit performed by a CEDA Wx assessor. The audit leads to development of a work order that may comprise measures in the following categories:2

- Retrofit measures: insulation, compact fluorescent lamps, refrigerator replacement, low-flow shower heads and faucet aerators, heating system replacement, window and door replacement

- Air sealing measures

- Health and safety measures (limited to $600 per unit): handrails, fire extinguishers, gutters, downspouts, and decommissioning of unvented space heaters

- Incidental repair measure (limited to $500 per unit).

DOE Wx program funding requires that the entire building or house receive a savings-to investment ratio of 1 or greater before it can be weatherized.3 Software tools are used to estimate the savings from various measures. Costs per work item are sent to bid by approved contractors. The state-level administration of IHWAP sets a limit of $5,200 to the expenditure for each eligible unit. Approved contractors participating in the CEDA Wx programs implement the work scope. Upon completion of the work, CEDA Wx assessors conduct inspection of the work ermal performance of masonry wall assemblies and the lack of opportunity for improvement at levels of investment commensurate with typical Wx programs. The furring cavity between the brick wall and the interior finish does not provide adequate space for effective insulation. The program has not pursued measures based on interior wall build-out for insulation due to anticipated costs and complications. Neither has insulation and recladding at the exterior been incorporated into available measures. Such strategies have been generally regarded as too unfamiliar to the contractor base and as potentially representing fire safety concerns.

In 2011, CEDA was awarded special grant funding through the SERC program, an innovation grant program of DOE. This grant allowed CEDA to apply resources beyond regular Wx program allocations at a limited number of selected projects. The grant allowed the budget for a single-family unit to increase by $9,600 and for multifamily unit by $6,400.

The SERC innovation grant has provided CEDA the opportunity to pursue limited implementation of various strategies to address building performance weaknesses that have heretofore been out of reach of the Wx programs. One of the innovations that CEDA opted to pursue with this funding is exterior insulation and cladding of masonry walls.

2.3 BSC-CEDA Research Collaboration

In 2010 CEDA and BSC gathered CEDA Wx personnel, management, and selected consultants to envision a path toward significantly increasing performance of homes treated through CEDA programs and, in particular, masonry buildings. These meetings identified major packages of measures to be researched through prototype and/or pilot implementations. Taken together, the major packages describe a comprehensive high performance retrofit. The first package that the collaboration evaluated through a series of implementations was an advanced Wx approach for the roof of 1½-story brick bungalow homes (see Neuhauser 2012).

The SERC grant provided a potential opportunity for the BSC-CEDA collaboration to evaluate another major package for masonry buildings: insulating and over-cladding of masonry walls. BSC and CEDA began the preliminary work of developing schematic details for the over-clad assembly and evaluating a number of potential building candidates.

After BSC and CEDA began this preliminary work, two factors emerged that resulted in disruptions to the collaborative effort. On the one hand, management changes within the CEDA organization resulted in uncertain support for the project. On the other hand, the wider national political climate created some uncertainty as to whether BSC would be able to support its involvement in the project. As a result, funding and implementation of the exterior insulation and over-cladding project were uncertain during significant portions of the originally projected project timeline. This affected BSC’s ability to participate in the project. In fact, BSC’s participation was essentially suspended for a period from prior to contractor bidding until just prior to the start of construction. As a result, critical windows of opportunity to provide guidance to contractors and to obtain pre-retrofit performance data were missed. The availability of CEDA resources was also constrained during the project. This hampered collection of certain post- retrofit performance data. . .

Download the complete report here.

Footnotes:

- Percentages reported are based on 2010 data.

- Note that the list of allowable measures in the program has changed slightly since the period of research.

- Typically, the value of savings is taken as the present value of recurring savings for a period of time at a standard discount rate. The present value of savings is then compared to the initial cost or investment of the measure.