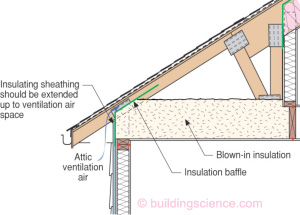

Cavity insulation combined with insulating sheathings are common in residential wall construction. Cavity insulations can be categorized as rolled batt; blown-in or loose-fill (fibrous insulation—cellulose, fibreglass, rock or slag wool—supported by netting or reinforced polyethylene or blown into closed cavities); damp spray (fibrous insulation with moisture activated adhesive or binder); and spray foam. Insulating sheathings are typically extruded and expanded polystyrenes, foil- and fiber-faced isocyanurates, and rigid fibreglass. Roof/attic insulations are typically blown fibreglass, blown cellulose, fibreglass batt, and spray foam.

For insulation to perform as intended, it must be installed correctly. Correctly installed insulation forms a continuous thermal barrier that is as even as practical.

It bears reminding that health and safety precautions must be followed for insulation installers and those remaining in the vicinity of the insulation installation. Performance of cavity insulations are degraded primarily by two factors:

- Absence of insulation

- Convective looping in and around the insulation

The first factor is a contributor to the second. Gaps, voids, and incomplete cavity fills leave spaces in which convective looping can occur.

An omission or degradation in any type of insulation will reduce the insulating performance of the overall assembly.

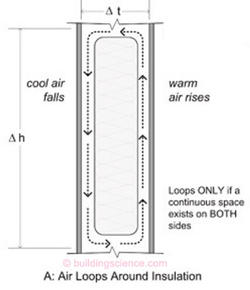

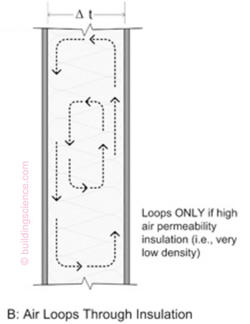

One of the heat exchange mechanisms that cavity insulations are intended to control is convection. When convective looping is able to occur in or around the insulation, its function is subverted. Also, air moving through insulation because of wind or other pressures can also subvert its performance. Therefore, low density fibrous insulations should be covered by air barriers in areas subject to air movement.

Rolled Batt Insulation:

Batt insulation can be a very cost effective option where the framing cavities are of uniform size and where the width and depth matches that of the rolled batt insulation. With rolled batt insulation care must be taken to cut the insulation to fit snugly in cavities and around all obstructions without compression. When batts are cut too short, too narrow, or too wide around obstruction, gaps and the associated problems result. Also when batts have been cut too big for the cavity or have not been cut to adequately accommodate obstructions there will tend to be compression and gaps of incomplete thickness (“rolled shoulders” at framing or wrinkles in the field of the batt). Compressing batt insulation also reduces its thermal resistance (effectively, its R-value). Batts should also be fluffed to full thickness so that they will be in contact with the cavity enclosure on all six sides and not leave gaps for convective looping. Higher density rolled batts are more effective at inhibiting convective looping within the insulation.

Blown-in or Loose-fill Insulation:

Blown-in insulations can be very effective at filling irregularly shaped framing cavities, inaccessible cavities, and completely filling cavities around obstructions. At sufficient densities, blown-in insulations can also inhibit convective air flow. Care must be taken to completely fill cavities without leaving holes or voids. The blown-in insulations must be applied at sufficient density to protect against settling which would also leave holes and voids.

Damp Spray Insulation:

Damp spray insulations can effectively fill open cavities and then be trimmed to be flush with framing. With sufficient adhesive/binder strength, some damp-spray insulations can be used in cavities that will not be enclosed such as attic knee walls and tricky areas such as rim joist areas. At sufficient densities, damp spray insulations can also inhibit convective air flow. Care must be taken to completely fill cavities without leaving holes or voids as the adhesive properties of the insulation can prevent the insulation from “flowing” in behind obstructions.

Damp spray insulations should only be used in wall assemblies that are able to dry toward the interior or exterior. Generally, where the assembly will require a vapor retarder to the interior of the assembly, the insulation should be allowed to dry before application of the vapor retarder.

Spray Foam Insulation:

Spray foam insulations can effectively fill framing cavities, irregular spaces, and around obstructions. The adhesion of spray foams (provided substrates are compatible and clean) allow spray foams to be applied in cavities that will be left open. Spray foam insulations provide excellent air sealing characteristics and can be used to provide air barrier continuity at difficult details such as across rim joist/band joist assemblies. Use of low density foams result in flexible installations, forgiving of movement. Higher density foams are more abuse-resistant but are not as tolerant of movement.

Because of the rapid expansion of spray applied insulation during curing—particularly most low-density spray foams—care must be exercised in insulating behind obstructions or in confined cavities.

Spray foams must be mixed at the proper chemistry to achieve the intended performance.

Installation of Cavity Insulation Details

Figures 1A and 1B

Convective Air Loops that Reduce Thermal Control of Insulation

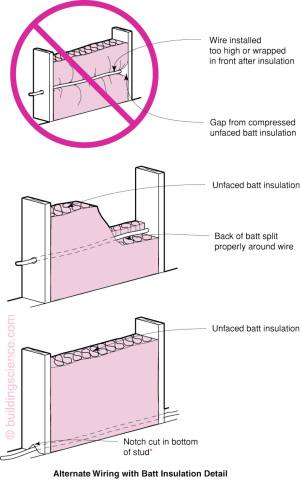

Figure 2

Installing Batt Insulation in Cavity with Electrical Wiring

- Roll batt insulation should not be shoved behind obstructions

- Insulation materials should be slit, cut or notched to fit neatly around obstructions

- Insulation material should be fluffed to full thickness

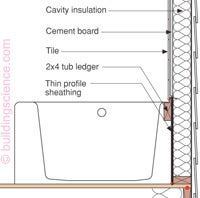

Figure 3

Insulation Cavity Enclosure Behind Tub

- Thin profile sheathing protects insulation from convective looping and prevents insulation from slumping out of cavity

Figure 4

Insulated Knee-Wall with Vented Attic

- House wrap or rigid sheathing material on the attic side of the knee-wall insulation protects the insulation from wind washing