BSC collaborated with Greencraft Builders, LLC in Colleyville, TX on a 2009 prototype house called the Colleyville House. This house demonstrates the energy efficiency and durability upgrades that Greencraft currently promotes in all of their products. The Colleyville house is located in Colleyville, TX, about 25 miles North West of Dallas. The house was designed by William Peck and Associates, an award winning architect specializing in sustainable energy efficient architecture.

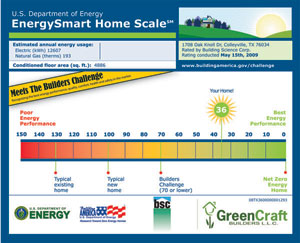

BSC has been collaborating with Greencraft homes since 2005 and have forged a valuable working relationship. BSC provided consulting services for Greencraft and recommended numerous efficiency and durability improvements. One of the main features that separate this home from previous projects is the inclusion of a high efficiency ground source heat pump. Other key upgrades include an unvented roof with low density spray foam insulation and supplemental dehumidification. Also included are LoE3 next generation spectrally selective glazing treatment and very low enclosure infiltration. A full CFL lighting package plus Energy Star® appliances help to achieve a HERS Index of 36.

Project Team: Greencraft Builders, LLC, Building Science Corporation

Location: Colleyville, Texas

Description: 4,886 ft2 two-story single family home

Completion Date: March, 2009

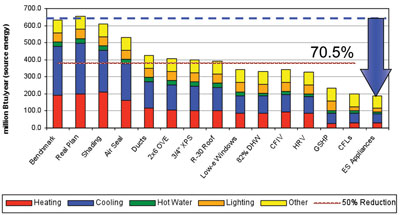

Estimated Annual Energy Savings: Average 70.5% projected source energy savings relative to the 2008 Building America Benchmark

Project Website: http://colleyvilleecohouse.com/

Construction

Greencraft constructs with full Advanced Framing in their walls, roof, and frame floor. This includes 2x6 studs at 24” o.c. plus two stud energy corners and single top plates. Greencraft employs stack framing so that wall and floor framing members are aligned to transfer loads efficiently through the structure.

The wall cavity is fully insulated with low density open cell spray foam to an R-20. The roof is an unvented cathedralized roof with R-30 low density open cell spray foam installed to the underside of the roof sheathing.

The Colleyville house was able to procure high quality fiberglass framed windows with state of the art LoE3 spectrally selective glazing coating. This resulted in an NFRC full unit SHGC rating of 0.34 with a U-value of 0.29. This glazing coating, coupled with extensive overhangs in the floor plan, results in a greatly reduced cooling peak load and annual cooling energy use.

A high efficiency ground source heat pump (18.8 EER/4.1 COP) is installed along with a integrated supplemental dehumidification. All the equipment and ductwork is located in the unvented cathedralized attic to save living space. Jump ducts provide passive returns from the bedrooms. High efficiency exhaust ducts are installed at all the bathrooms and at the kitchen hood.

Builders Challenge Certificate

Enclosure Design

Roof Assembly: Unvented roof with R-30 open cell spray foam and fully-adhered waterproof membrane

Fully-adhered waterproof membrane

Wall Assembly: Fully advanced framed structure; R-24 wall with R-20 open cell spray foam and 3/4” XPS sheathing

Advanced framing with XPS sheathing

Window Specifications: Vinyl framed double glazed windows: U=0.34, SHGC=0.29.

Air Sealing: The design infiltration rate is 2.5 in2 leakage area per 100 ft2 of enclosure area. Low density open cell spray foam installed in wall and roof cavities. Low expanding open cell spray foam installed around windows and mechanical and electrical penetrations throughout the enclosure.

Low density open cell spray foam

Foundation Assembly: Slab-on-grade foundation; uninsulated with Termimesh® termite mitigation system and sill seal.

Mechanical Design

Heating and Cooling: 4.1 COP/18.8 EER ground source heat pump (see piping).

Ventilation: Fantech energy recovery ventilator (ERV).

Energy recovery ventilator (ERV)

Supplemental Dehumidification: GeneralAire whole-house dehumidifier integrated with HVAC system.

DHW: 0.82 EF instantaneous water heater with an add-on storage tank for hot water from ground source heat pump.

Lighting: ENERGY STAR® CFLs

Appliances: ENERGY STAR® dishwasher, refrigerator and clothes washer.

Ventilation

Greencraft Builders, LLC utilizes Central Fan Integrated Supply ventilation that draws outside air via a 6” flex duct to the return plenum of the HVAC system. This allows for the introduction of outside air to the living space whenever space conditioning is already operating. The GeneralAire whole house dehumidifier draws air from the main living space and supplies dehumidified air to the supply plenum of the HVAC system. An Aprilaire® Ventilation Control System 8126 communicates with the air handler to employ fan cycling. Fan cycling will turn on the fan at a 33% duty cycle (10 minutes on, 20 minutes off) in order to provide outside air during periods of no space conditioning. A 6” mechanical damper is installed on the 6” outside air duct. This is controlled by the fan cycler and will close off the outside air duct during periods of consistent space conditioning to prevent over ventilation of the living space.

Bathroom exhaust fans plus a kitchen hood are installed to provide spot ventilation when necessary. These are all routed to the outside and are not re-circulating fans. One of the bathroom fans is rated to provide ASHRAE 62.2 ventilation so that the house can be operated at that rate if needed.

Moving Forward

The open house period of the Colleyville house has ended and now Greencraft is ready to start design on the Net Zero Energy Lewisville Eco House. One of the major design upgrades for this house will be the installation of a heat pump with integrated supplemental dehumidification. AAON Inc. has designed a residential heat pump that integrates modulating gas reheat to allow for dehumidification separate from cooling. This technology has been implemented successfully in commercial buildings for years and now will provide supplemental dehumidification in residential buildings.

Design and Construction Challenges Second, the homeowners requested a dark metal roof for aesthetic purposes. Greencraft had to work to find an ENERGY STARr® rated dark metal roofing material in a short period of time. Fourth, a considerable amount of select fill had to be obtained to prepare the ground surface properly. This was due to the fact that the previous home on this site had a pier and beam foundation. The existing foundation was fully removed and that left large cavities that needed to be filled. Then, the resulting ground had to be compacted 95% to meet the structural demands and this had to be tested and verified in the field. |