In June of 2009, National Grid launched a pilot program intended to demonstrate Deep Energy Retrofits (DER) in existing Massachusetts homes. The pilot program provides financial incentives and technical support to projects that commit to achieving significant energy reduction and successfully complete a long application process. The open application process is intended to bring a variety of housing types and retrofit approaches into the pilot.

As the Technical Team in this pilot, Building Science Corporation (BSC) provides evaluation and approval of project plans; technical support to project teams; conducts inspections, verification and testing; presents Deep Energy Retrofit workshops; and also supports the National Grid in program design and administration.

January of 2010 saw the completion of the first project participating in the National Grid Deep Energy Retrofit Pilot. This project involved the renovation of an 18th century Cape. While the owners and builder had already planned a comprehensive renovation, financial and technical support from National Grid and BSC, respectively, allowed this project to achieved a super insulated enclosure (~R-35 walls, R-50+ roof, R-20+ foundation), extensive water management improvements, high efficiency heating and water heater, and state of the art ventilation. Air leakage testing found the enclosure and the new duct system to be extraordinarily air tight.

Project Team: Wright Builders, Inc., Building Science Corporation, National Grid, Massachusetts

Location: Belchertown, Massachusetts

Description: Comprehensive renovation of circa 1760 cape, 1,435 ft2 above-grade conditioned space, one-and-a-half story, three bedroom, one-and-a-half bath home

Completion Date: January 2010

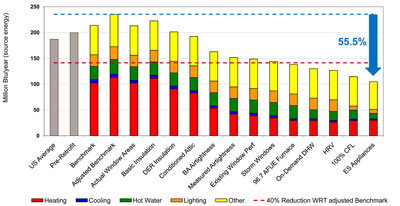

Estimated Annual Energy Savings: 55% energy use reduction compared to the homesize-adjusted Building America benchmark; $2,800 estimated annual savings

Design

Prior to the retrofit, this largely uninsulated 18th century cape offered little in the way of thermal comfort and exhibited a lack of proper water management. A pre-retrofit blower door test of this 1,400 ft2 home measured above 10,000 cfm50! The house used approximately 7 cords of wood per year and the owners reporting living in the room with the wood stove during the winter. Standing water was observed in the basement prior to the retrofit. Windows had been replaced relatively recently with double glazed low-E wood-framed units but, unfortunately, these had been installed without any flashing or air sealing.

As an alternate to the already comprehensive renovation planned, the builder offered a high performance package to meet the objectives of the National Grid Deep Energy Retrofit Pilot. This package included extensive use of medium density spray foam insulation and construction of a 2x4 stud wall to the interior of existing exterior walls in order to accommodate a greater thickness of foam.

BSC expressed concern that adding a thick layer of air-impermeable, vapor-retarding insulation to the interior without assuring proper water management on the outside, would put this 250 year-old structure at risk. BSC called for remedial flashing at windows and inspection of other flashing details. Inspection of water management details revealed numerous problems which necessitated installation of new flashings and corrections to the drainage plane.

The initial renovation plans had already envisioned significant trenching, piping and gravel in the basement to control the obvious water problems. The Deep Energy Retrofit plan added insulation to the walls and an insulated slab.

The owners and builder were disinclined to replace functioning and relatively new windows in order to achieve what was perceived to be a modest gain in thermal performance. The owner and builder proposed a number of strategies to improve the thermal performance of the existing windows. Analysis by BSC found that high quality exterior storm windows offered the best combination of improved thermal performance, interior surface condensation control, and exterior rain shielding for the windows.

After some discussion and analysis by BSC, the builder elected to include the small attic space within the thermal enclosure. This allowed for the new ducted heating distribution system to be entirely contained within the thermal enclosure.

Enclosure Design

Roof Assembly: Compact (unvented) roof assembly with existing 2x8 rafter framing and 2x3 cross furring, framing cavity and portion of furring cavity filled with R-56 Demilec Heatlok Soy™ medium density spray foam insulation.

Wall Assembly: 2x4 stud wall constructed to inside of original post and beam frame with 1” gap between existing and new framing. R-32 (~5”) medium density spray foam insulation sprayed into wall cavities and over rim beam.

Window Specifications: New Harvey Tru Channel storm windows over existing wood-framed, double-glazed, low-E windows; approx. composite performance: U=0.25, SHGC=0.52.

Air Sealing: Continuous layer of medium density, closed-cell spray foam insulation provides air flow control in the field of the wall and roof assemblies. Spray foam insulation also applied at rim beams and in a floor assembly over a crawl space. Low-expansion foam sealant applied around windows and doors, and at any mechanical or electrical penetrations through the enclosure.

Foundation Assembly: Conditioned basement with 3-5” medium density spray foam insulation applied directly to field stone and concrete foundation walls. Spray foam insulation painted with Blaze Lok 1B™ ignition barrier paint. A 12” high strip of 2” XPS as the slab perimeter thermal break also allows foundation walls to drain to the sub-slab drainage system. Several trenches with drainage pipe connected to drain and filled with gravel manage bulk water. New cast concrete basement floor slab over 6 mil poly, 2” XPS and continuous bed of gravel.

Construction

The Builder had already designed the renovation project and contracted with the homeowners when the National Grid Deep Energy Retrofit Pilot Program was launched less than two months before the scheduled start of construction. Nonetheless, the builder and homeowners decided to explore participation in this pilot program. The builder submitted a preliminary application which described the builders planned changes to achieve the Pilot’s high performance objectives.

As part of its evaluation of the DER plan, BSC identified several issues that would need to be resolved before the project could be accepted into the National Grid pilot. These issues included the heating system efficiency and configuration, window performance, and water management of the wall system. Under the time pressure of impending construction start, BSC and the builder worked to identify resolutions to these issues that fit within the homeowners’ established budget and the conditions of the project and also satisfied the objectives of the pilot. A high efficiency, ducted heating system, storm windows and window flashing remediation were incorporated into the renovation plans. During construction, the builder sought BSCs review of existing water management conditions. These investigations identified several conditions (beyond those identified in the plan) which required remediation.

Mechanical Design

Heating: 96.7% AFUE sealed combustion propane furnace in conditioned space. High SEER coil installed for future connection to air-source heat pump.

Sealed Combustion Propane Furnace

Ventilation: High efficiency heat recovery ventilator (HRV) with dual ECM motors and 74% recovery efficiency. Outside air supply ducted to heating system distribution, exhaust air taken from bathroom.

Heat recovery ventilator (HRV)

Space Conditioning Distribution: Insulated sheet metal trunks with insulated flex run-outs. Ducted return in each bedroom plus two additional returns in first floor areas. Entire distribution system within thermal enclosure.

Space Conditioning Distribution

DHW: 0.86 EF on-demand propane-fired water heater.

On demand gas domestic hot water

Lighting: Hard wired ENERGY STAR®CFL lighting plus high efficacy (60 lumen/Watt) LED lighting.

Appliances: ENERGY STAR® dishwasher, refrigerator and clothes washer.

Testing

After the renovation was substantially complete, BSC inspected the home and conducted performance testing of systems to verify that performance objectives were met. BSC conducted blower door testing to measure the air tightness of the building enclosure and Duct Blaster® testing to measure the duct leakage of the space conditioning distribution.

The target air tightness of the closure in BSC’s Building America work is 2.5 in2 of effective leakage area per 100 ft2 of building enclosure area. For this home the target corresponds to ~925 cfm at 50 Pascals (cfm50) or 0.25 cfm50 per ft2 of enclosure. The National Grid Deep Energy Retrofit Pilot set an even more aggressive air leakage target of 0.1 cfm50 per ft2 of enclosure. BSC measured air leakage of 468 cfm50 or 0.13 cfm50 per ft2 of enclosure. While falling just short of the Pilot target, these results are, nonetheless impressive and are a testament to how well the builder used the medium density spray foam to create a continuous air flow control layer around the building.

BSC conducted duct leakage testing and found total duct leakage for the nominal 3 ton system to be 98 cfm at 25 Pascals. Testing measured zero cfm of leakage to the outside as was expected with the distribution system entirely contained within the very air tight thermal enclosure of the building.

Moving Forward

BSC conducted analysis of the completed project to evaluate its predicted energy use under standard operating conditions. Because the homeowners evince a very low energy lifestyle, it is expected that the actual energy use for this home will be well below that predicted for the home under standard operating conditions.

Agreements between National Grid and the homeowners stipulate that the homeowners will make energy consumption data available for review and analysis for a period including at least two full heating seasons after completion of the project.

The homeowners have been thrilled with the transformation of their home and have enthusiastically shared information to help others considering a Deep Energy Retrofit path.

Design Challenge: Converting a Cold, Wet Cellar into a Useable Space The renovation plans included providing access for the homeowners to wheel their bicycles into the basement. Because these residents of a rural and hilly part of Massachusetts relied upon their bicycles for transportation, condition of the space in which they store their vehicles is very important. Prior to the renovation project, the basement was a cold and damp space. It often contained standing (sometime flowing) water. The homeowner and builder combined efforts to dig trenches in the basement, install drainage piping draining to daylight, and load several cubic yards of gravel into the basement. To supplement these liquid water control measures, BSC recommended an insulated concrete slab in contact with a polyehtylene sheet to provide condensation control, vapor diffusion control and to control convective (air flow) transfer of moisture and soil gases into the space. BSC also provided a detail to ensure that, after spray foam insulation is installed against the foundation walls, any water that leaks through the walls is able to drain into the sub-slab drainage system. |