Blue Hawaii[1]

Hawaii is a magnificent place – except if you want to build there. Huh? What’s so difficult about building on islands in the middle of the Pacific? Check out Photograph 1. Waikiki Beach. Blue water. Blue sky. Wow. Not a problem if you want a tan and if you want to surf – even better – not a problem if you want to drink Blue Hawaiians[2] on the beach watching the scenery walk by.

Photograph 1 - Waikiki Beach: Blue water. Blue sky. Wow.

But building on the beach? Or near the beach? By the way everything in Hawaii is near “the beach”. Not so easy. The Pacific is salt water – just showing off my Canadian public school education here – and there are waves and the salt water gets aerosolized and is carried by the magnificent breezes everyone raves about right into your vented attics and into your wall assemblies and corrodes everything and messes up your stucco. Stucco? Yes, salt water spray is not a fun thing on stucco. Just ask those folks on South Beach in Florida if you doubt me…or go visit Galveston, Texas.

Oh, yeah, also humidity. Hot, humid, tropical type of humidity. Worse than Houston, but with much better scenery. And wait for it, worst of all, termites. Did I mention termites? The worst kind….like Australian termites but with an attitude, grass skirts and a penchant for SPAM[3].

In Hawaii people don’t want to build out of wood because of the termites so they use steel framing. Also in Hawaii people don’t want to build out of steel framing because of the corrosion so they use wood. The therapy bills have been expensive trying to sort this out. So we have a mixture of steel framing and wood and engineered wood.

First, and foremost, Hawaiians deal with the termites. The approach is a combination of “interspecies chemical warfare” and “physical barriers”. Back in the old days we had fabulous termiticides called chlordane and heptachlor. What made them so fabulous was that the little buggers….the termites… couldn’t detect their presence and they would wander through them and die. The coverage didn’t have to be perfect. You sort of spread the termiticides around in an imperfect manner and the laws of probability and chance would work for you and eventually the little buggers would crawl through them and they would become toast. Problem was chlordane and heptachlor caused cancer in humans among other nasty effects. The risks were so bad that they were banned in the 1980’s.

The replacement termiticides were as deadly to termites as chlordane and heptachlor but the little buggers could detect the replacements. The termites would say, hey, I am not going there, that stuff will kill me. So the termites, being patient, would search around and find a gap in the “chemical barrier”. A gap could be a “footprint” of someone walking over the surface of the ground that was treated before the foundation was placed. Kind of crazy if you think about it? No way you could treat the ground with a perfect chemical barrier. The termites got the upper hand….for twenty years.

Now we have something called fipronil which is as deadly to termites as chlordane and heptachlor but not as risky to humans. And even better, the termites can’t detect it so it does not have to be applied as a perfect barrier. This is huge. Humans are back winning the game.

Having said that, even though we are back winning the game “chemically”, we learned a bunch of stuff when we were losing the game that we can still use. The Australians, with their own miserable tough termites, taught the rest of us a thing or two when we were unable to use chemicals effectively and safely. Stainless steel mesh. Yup, even an Australian termite can’t chew through stainless steel mesh. Australian concrete slab-on-grade design began to use stainless steel mesh at penetrations through the concrete to create rather impressive physical barriers to the termites. When you couple ground treatment with fipronil and stainless steel physical barriers around penetrations you pretty much have won.[4]

You want to see some fabulous concrete slabs? Ask the Marines at Kaneohe Bay, O’ahu. Check out Photograph 2 and Photograph 3. Note the complete polyethylene ground cover, taped joints, wrapped under the perimeter slab edge and tied into the perimeter slab forms with a polyethylene “hem”. Even better, note the stainless steel mesh clamped to the pipe penetration that gets cast into the slab creating a physical termite barrier. The ground is treated under the slab and at the slab perimeter with fipronil prior to the installation of the polyethylene ground cover.

Photograph 2 – Slab Done Right: Note the complete polyethylene ground cover, taped joints, wrapped under the perimeter slab edge and tied into the perimeter slab forms with a polyethylene “hem”. The ground is treated under the slab and at the slab perimeter with fipronil prior to the installation of the polyethylene ground cover.

Photograph 3 – Physical Barrier: Even better, note the stainless steel mesh clamped to the pipe penetration that gets cast into the slab creating a physical termite barrier.

On to Hawaiian residential walls. They sure like their steel framing (Photograph 4). Termites don’t eat steel. Not a lot of wood stud framing. But steel rusts. Where the steel framing is in contact with the concrete slab the bottom track of steel is wrapped with a peel and stick membrane to reduce the risk of corrosion (Photograph 5). But it is impractical to get rid of all wood. So you minimize it and move it up away from the ground and those miserable termites (Photograph 6).

Photograph 4 – Steel Framing: Even with steel framing we typically have a wood top plate and wood framing around punched openings such as windows.

Photograph 4 – Steel Framing: Even with steel framing we typically have a wood top plate and wood framing around punched openings such as windows.

Photograph 5 – Steel Rusts: Termites don’t eat steel. Not a lot of wood stud framing. But steel rusts. Where the steel framing is in contact with the concrete slab the bottom track of steel is wrapped with a peel and stick membrane to reduce the risk of corrosion.

Photograph 5 – Steel Rusts: Termites don’t eat steel. Not a lot of wood stud framing. But steel rusts. Where the steel framing is in contact with the concrete slab the bottom track of steel is wrapped with a peel and stick membrane to reduce the risk of corrosion.

Photograph 6 – Minimize Wood: It is impractical to get rid of all wood. So you minimize it and move it up away from the ground and those miserable termites.

There is still no practical replacement for engineered wood sheathing such as oriented strand board (OSB) in terms of shear. Nothing wrong with OSB except it burns and it rots and termites like it. But you can cover it on both sides with stuff that does not burn such as gypsum board interior linings and fiber cement, stucco or brick claddings. And you can provide water management and air management to control moisture and associated decay and mold….and you can keep it up from the ground away from termites.

Photograph 7 shows an OSB sheathing with an integral water control layer on the face of the OSB. The joints in the OSB are taped to provide water control layer continuity and air control layer continuity. The OSB also acts as a “vapor throttle” reducing inward vapor drive. Note in hot, humid climates the dominant vapor flow is from the outside to the inside. Also note the “concrete skirt” around the perimeter of the foundation to keep insects, vermin and plant growth away from “where the building touches the ground”. More “physical barrier” stuff. Don’t knock it, it works.

Photograph 7 – OSB Sheathing: Note the integral water control layer on the face of the OSB. The joints in the OSB are taped to provide water control layer continuity and air control layer continuity. The OSB also acts as a “vapor throttle” reducing inward vapor drive. Note in hot, humid climates the dominant vapor flow is from the outside to the inside. Also note the “concrete skirt” around the perimeter of the foundation to keep insects, vermin and plant growth away from “where the building touches the ground”. More “physical barrier” stuff. Don’t knock it, it works.

Photograph 8 shows an “airtight” seal between the sheathing and the concrete foundation. We do not want “salty” air getting into the wall framing and causing havoc with our steel studs and connections.

Photograph 8 – Continuous Seal: Note the “airtight” seal between the sheathing and the concrete foundation. We do not want “salty” air getting into the wall framing and causing havoc with our steel studs and connections.

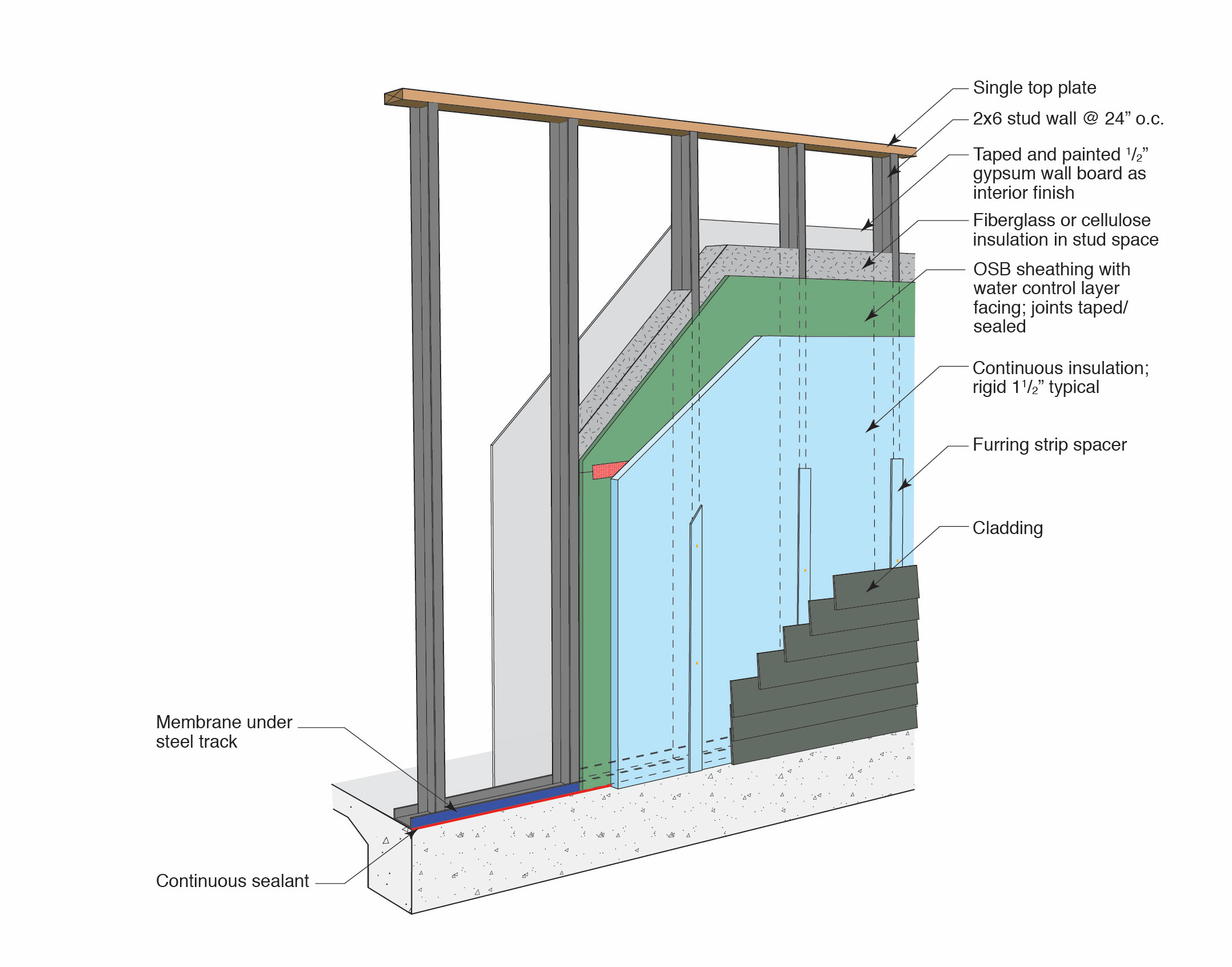

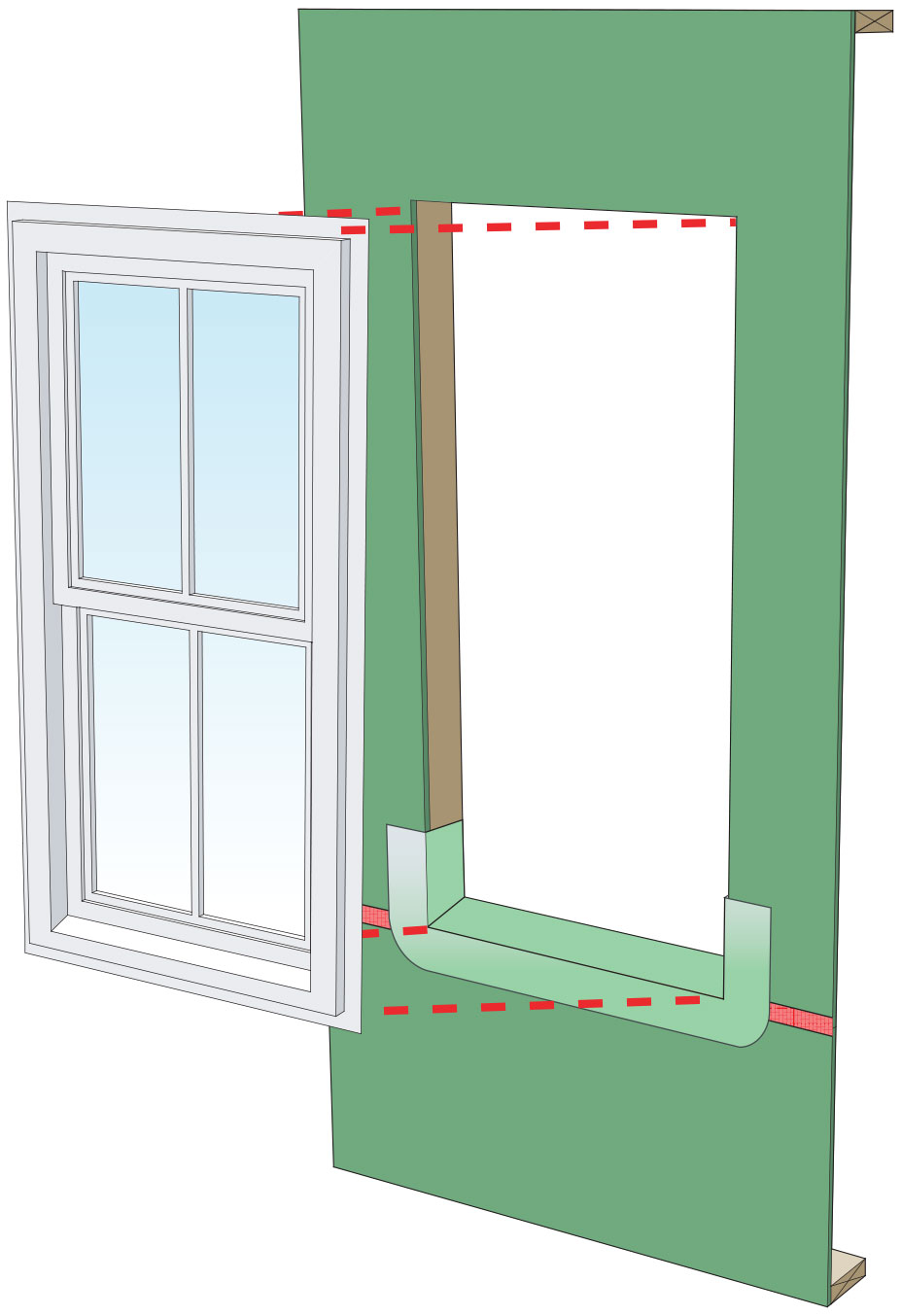

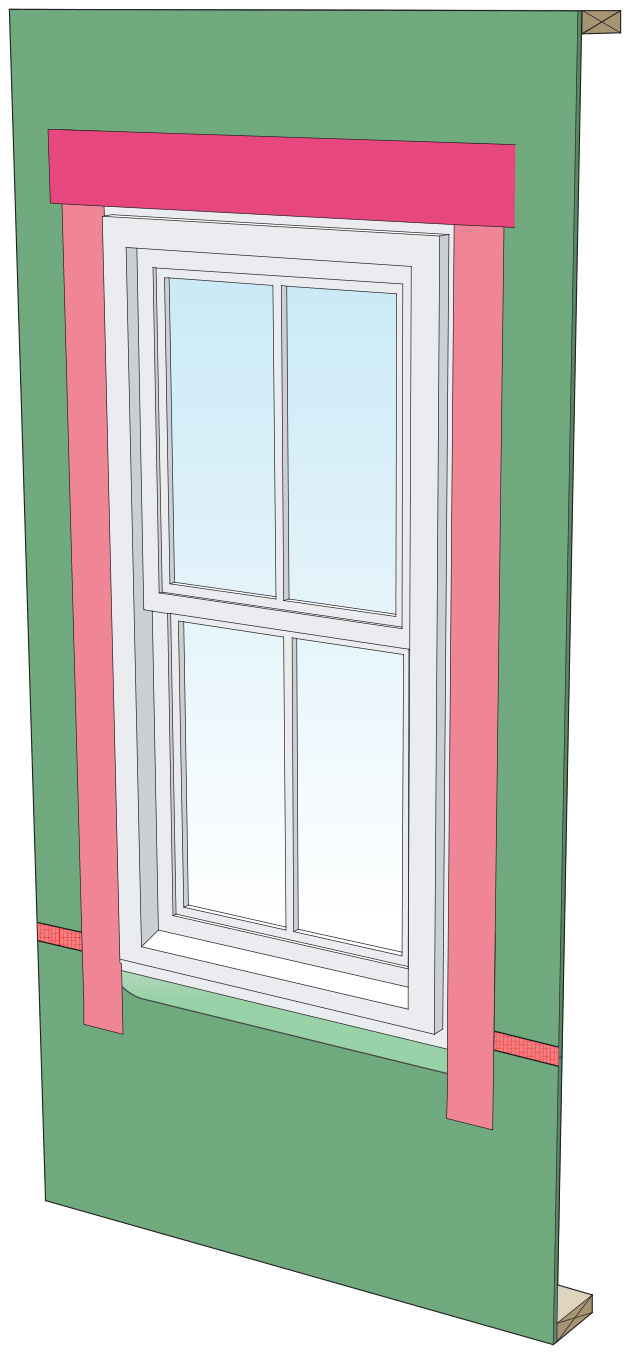

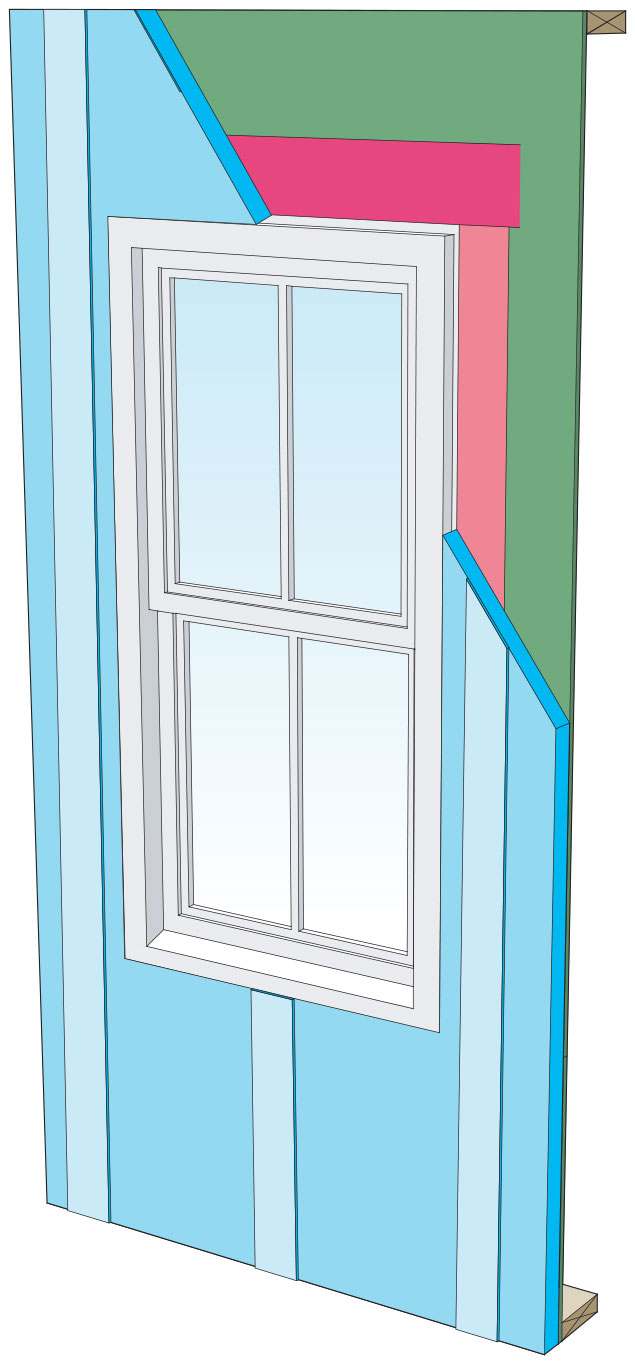

Now, everyone knows that steel framing has lousy thermal performance. We need continuous insulation over the exterior of the steel framing (Figure 1). Pick any continuous insulation you want. They all work in this configuration. The windows and punched openings are handled as shown in Figure 2. No need to “picture frame” or use a “ROESE” - a “rough opening extension support element” (see “BSI-022: The Star-Crossed Lovers of Building Science", November 2016).

Figure 1 – Steel Framing: Everyone knows that steel framing has lousy thermal performance. We need continuous insulation over the exterior of the steel framing. Pick any continuous insulation you want. They all work in this configuration.

Figure 2a – Window Installation: Note the “pan flashing” at the bottom of the rough opening and note that the window flange is installed directly on the OSB sheathing. Figure 2b – Window Installation: Flashing tape is used to provide water control layer continuity and air control layer continuity. Figure 2c – Window Installation: Continuous insulation is installed over the OSB sheathing. Note that the water control layer is behind the continuous insulation.

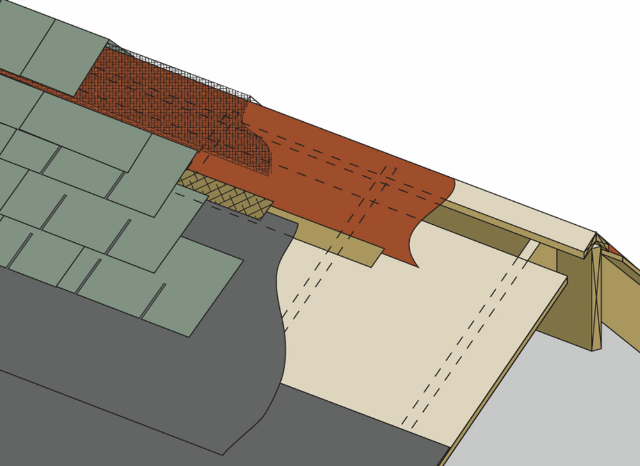

On to Hawaiian residential roofs. Vented roofs in Hawaii lead to corrosion of roof truss connections. Easy solution. Don’t vent roofs in Hawaii. Move the insulation from the “flat” to the “slope” (Photograph 9) and install a vapor diffusion ridge vent to allow vapor to exit the assembly via vapor diffusion (Figure 3 and Photograph 10). No air change between the attic and the exterior occurs. This has three huge benefits. First, no salty air into the attic and no corrosion. Second no exterior humid air into the attic to cause ducts to sweat and a huge increase in airtightness of the entire assembly reducing part load humidity problems and providing a huge thermal benefit. Third, the ducts are now in conditioned space providing a huge thermal benefit. We were here before (“BSI-088: Venting Vapor”, July 2015).

Photograph 9 – Hawaiian Roofs: Don’t vent roofs in Hawaii. Move the insulation from the “flat” to the “slope” and install a vapor diffusion ridge vent to allow vapor to exit the assembly via vapor diffusion. No air change between the attic and the exterior occurs. This has three huge benefits. First, no salty air into the attic and no corrosion. Second no exterior humid air into the attic to cause ducts to sweat and a huge increase in airtightness of the entire assembly reducing part load humidity problems and providing a huge thermal benefit. Third, the ducts are now in conditioned space providing a huge thermal benefit.

Photograph 10 – Vapor Diffusion Ridge Vent: Standard ridge vent coupled with a vapor open, air tight and water tight membrane covering the slot opening in the roof sheathing at the ridge.

Photograph 10 – Vapor Diffusion Ridge Vent: Standard ridge vent coupled with a vapor open, air tight and water tight membrane covering the slot opening in the roof sheathing at the ridge.

Figure 3 – Vapor Diffusion Vent: Vapor diffusion ridge vent allows vapor to exit the assembly via vapor diffusion. No air change between the attic and the exterior occurs.

Not quite done. Still have a part load humidity problem to deal with. We have great windows, lots of thermal insulation, compact fluorescent and LED lights, and controlled ventilation. Not much of a sensible load. We do have a big latent load. We have to remove the humidity. Yup, we need a dehumidifier (Photograph 11). Now we are done.

Photograph 11 – Dehumidifier: Still have a part load humidity problem to deal with. We have great windows, lots of thermal insulation, compact fluorescent and LED lights, and controlled ventilation. Not much of a sensible load. We do have a big latent load. We have to remove the humidity. Yup, we need a dehumidifier.

Photograph 11 – Dehumidifier: Still have a part load humidity problem to deal with. We have great windows, lots of thermal insulation, compact fluorescent and LED lights, and controlled ventilation. Not much of a sensible load. We do have a big latent load. We have to remove the humidity. Yup, we need a dehumidifier.

Not so “blue” in Hawaii anymore. Not sad. Happy. Found love. Only blue ocean and blue skies….and dry, comfortable, rust free, termite free houses…..we will leave the stucco discussion for some other time.

Acknowledgements

Thanks to the Leathernecks of the 3rd Marine Regiment, Marine Corps Base Hawaii, Task Force Taro, for their courtesy. Since the days of the Barbary Pirates United States Marines have been known as “leathernecks” when leather neckbands were worn to protect Marines from the slash of the cutlass. Dad was a fighter pilot during the war and he said that when you were in trouble there was no better friend than a Marine.

References:

Lstiburek, J.W., BSI-022: The Star-Crossed Lovers of Building Science, November 2016.

Lstiburek, J.W., BSI-088: Venting Vapor, July 2015.

[1] Not too many folks remember that the song Blue Hawaii was first recorded by Bing Crosby in 1937, decades before Elvis Presley did it in 1961. But, to me, Elvis did it best. I think that Chadwick Gates was right not to want to manage the Great Southern Hawaiian Fruit Company.

[2] Vodka, Curacao, Rum. Curacao is a blue liqueur made from the laraha citrus fruit grown on the island of Curacao in the Caribbean.

[3] SPAM is an acronym for ”Specially Processed Army Meat” developed by Hormel in 1937. Hawaii has the highest per capita consumption of SPAM in the world. In Hawaii SPAM is known as “The Hawaiian Steak”. In an unrelated matter, some folks have referred to “OSB as the SPAM of wood….and SPAM as the OSB of luncheon meats”….

[4] Ground treatment and barriers at grade don’t help you with the flying termites. Vented attics are a real problem. Just visit Louisiana and ask a local. That is why unvented conditioned attics are catching on in termite country….