Flanged windows and foam plastic insulating sheathing.

Sometimes I don’t get it. Why would anyone deliberately recommend a thermal bridge when it is completely unnecessary? The window industry must hate the foam sheathing industry and as a result the foam sheathing industry hates the window industry. Yup, we have a vice versa. That is the only way I can explain it. Read on.

Anyone ever heard of a “ROESE”? Get used to it. It is a “rough opening extension support element”….“a projection” (“bump-out”) or extension to the structural wall framing at the rough opening perimeter” according to “AAMA” and “WDMA” respectively the American Architectural Manufacturer’s Association and the Window and Door Manufacturer’s Association. According to AAMA and WDMA a ROESE is necessary when a flanged window is installed with walls sheathed with exterior continuous insulation – insulating sheathing – most typically foam plastic insulating sheathing.

A ROESE is not a ROSE is not a ROSE by any other name…it is a thermal bridge.[1]

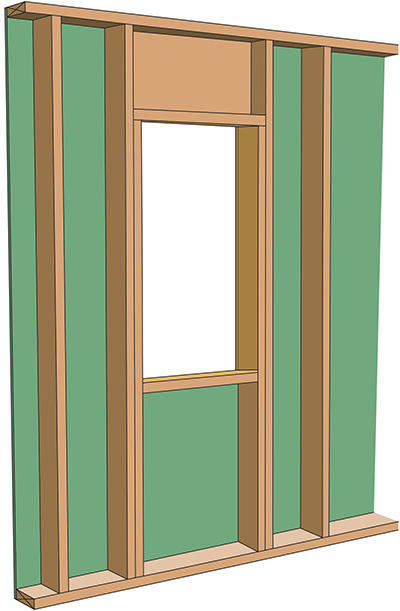

Let’s take a look at a ROESE in action. Photograph 1 shows a wall sheathed with oriented strand board (OSB). The window openings are “picture framed” with a wood “bump out”. The thickness of the wood “bump out” is intended to match the thickness of the continuous insulation to be installed later.

Photograph 1 – ROESE In Action - The wall framing is sheathed with oriented strand board (OSB). The window openings are “picture framed” with a wood “bump out”. The thickness of the wood “bump out” is intended to match the thickness of the continuous insulation to be installed later.

Photograph 2 shows the “bump outs” being “water proofed” with “peel and stick” flashing membranes. Note the primer being installed prior to the installation of the “peel and stick” flashing membranes. All good. All very good.

Photograph 2 – Water Proofing the ROESE - The “bump outs” are “water proofed” with “peel and stick” flashing membranes. Note the primer being installed prior to the installation of the “peel and stick” flashing membranes. All good. All very good.

Photograph 3 shows the windows being installed in the openings and a fully adhered water control layer being installed. The fully adhered water control layer is being integrated with the flashing membranes at the “bump out” openings. This is all good. Excellent, in fact. No water control issues. None at all. And no air control issues. So what is my problem? It is just that the wood “bump out” is a thermal bridge. What is the point of continuous insulation if we run a thermal bridge through it at every punched opening?

Photograph 3 – ROESE Window Installation - The windows are installed in the openings and a fully adhered water control layer is installed. The fully adhered water control layer is integrated with the flashing membranes at the “bump out” openings. This is all good. Excellent, in fact. No water control issues. None at all. And no air control issues. So what is my problem? It is just that the wood “bump out” is a thermal bridge. What is the point of continuous insulation if we run a thermal bridge through it at every punched opening?

According to AAMA and WDMA the function of the “bump out” is to support the weight of the window and to “allow direct structural attachment of the window in order to transfer wind loads to the structure” when you install exterior continuous insulation. Seems reasonable. Except why now? Never needed this before. The building industry has only about 35 years of historical experience showing that this is not necessary. Installing flanged windows over foam sheathing goes back to Deep Purple and Smoke on the Water.[2]

We have hung things off of foam sheathing to figure out long term creep performance (Photograph 4). We have hung things off of foam sheathing to figure out deflection and moments (Photograph 5). We have sucked on windows installed over continuous insulation to understand wind loading. We have blown on windows installed over continuous insulation to understand wind loading. Others have done this. Lots of others have done this. Even the foam industry has done this. Testing and field experience show that “bump outs” are not necessary. Did the window industry just “wake up”? What problem are we solving? Besides having to learn origami and apply the knowledge at window-to-wall interfaces and door-to-wall interfaces?

Photograph 4 – Creep Testing - We have hung things off of foam sheathing to figure out long term creep performance.

Photograph 5 – Deflection Testing - We have hung things off of foam sheathing to figure out deflection and moments. We have sucked on windows installed over continuous insulation to understand wind loading. We have blown on windows installed over continuous insulation to understand wind loading. Others have done this. Lots of others have done this. Even the foam industry has done this.

Seems to me that you only need a ROESE if you want to wrap the exterior of the continuous insulation with a building paper or other non-adhered film water resistive barrier because the building paper or other non-adhered film water resistive barrier needs to be attached to something and you need extremely rigid backing behind the flange to get the sealant behind the flange to act as a gasket between the sheathing and the building paper or other non-adhered film water resistive barrier. You don’t need to do this if you use the continuous insulation itself as the water control layer or if you install the water control layer behind the continuous insulation and the window is an “innie”.

If the window is an “outie” and the water control layer is behind the continuous insulation you need a ROESE – and that would smell as sweet by any other name. Similarly, if the continuous insulation is mineral fiber insulation boards (aka “stone wool”) – see “BSI-085: Windows Can Be A Pain”, April 2015.

Now I do not have any problem with installing building papers or other non-adhered film water resistive barriers over continuous insulating sheathing. None at all. It is just that in many applications you do not need to. You can use the exterior continuous insulation itself as the water control layer. But I don’t like tape at the joints. OK, you can go the building paper and non-adhered film water resistive barrier route. If I like the tape approach or the fully adhered membrane approach I don’t need the ROESE.

I also do not have any problem with installing building papers or other non-adhered film water resistive barriers behind continuous insulating sheathing. None at all. It is just that you do not need to install a building paper or non-adhered film water resistive barrier if you don’t want to. You can use the structural sheathing itself as the water control layer or install a fluid applied water control layer to the structural sheathing or install a fully adhered water control layer to the structural sheathing.

All of these options work. The options ought to be a design choice.

So let’s assume that we actually have a problem with structurally attaching flanged window through exterior continuous insulation. Just for yuks go with me on this. How does the window industry recommend attaching non flanged windows? Straps. Straps baby…..straps (Photograph 6). In fact that is the only way to install windows in high wind zones and seismic zones regardless of the sheathing type (Photograph 7).

Photograph 6 – Straps - How does the window industry recommend attaching non flanged windows? Straps. Straps baby…..straps. Note in the photograph we are using straps with a flanged window. I can’t see how this can possibly be an issue for the manufacturers of windows as they already allow the use of straps. In fact straps are the only means of attachment for non-flanged windows. How can adding straps to flanged windows not work? Exactly. There is no argument against this.

Photograph 7 – High Wind Zone and Seismic Zone Attachment – This window is in the high wind zone of coastal Florida. Straps make it work structurally. In fact that is the only way to install windows in high wind zones and seismic zones regardless of the sheathing type. Note that the thermal bridge goes away when straps are used.

So why not use straps to attach flanged windows through exterior continuous insulation and use the flanges for water management only? Easy peasy. The thermal bridge goes away. I can’t see how this can possibly be an issue for the manufacturers of windows as they already allow the use of straps. In fact straps are the only means of attachment for non-flanged windows. How can adding straps to flanged windows not work? Exactly. There is no argument against this.

We regularly use straps with flanged windows for ultra-high performance wall assemblies.

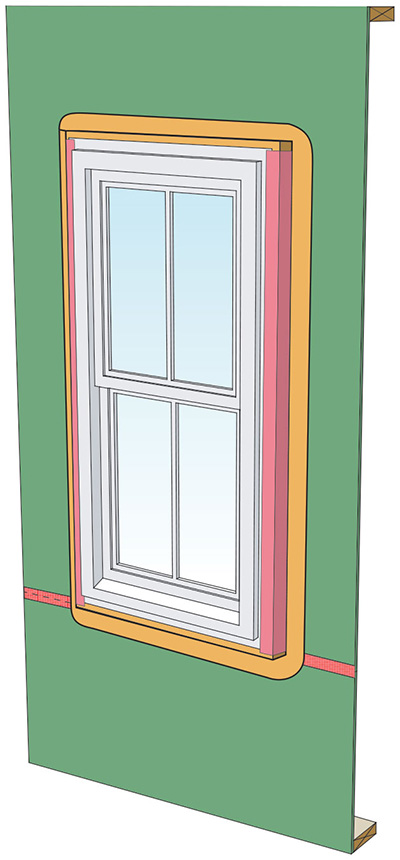

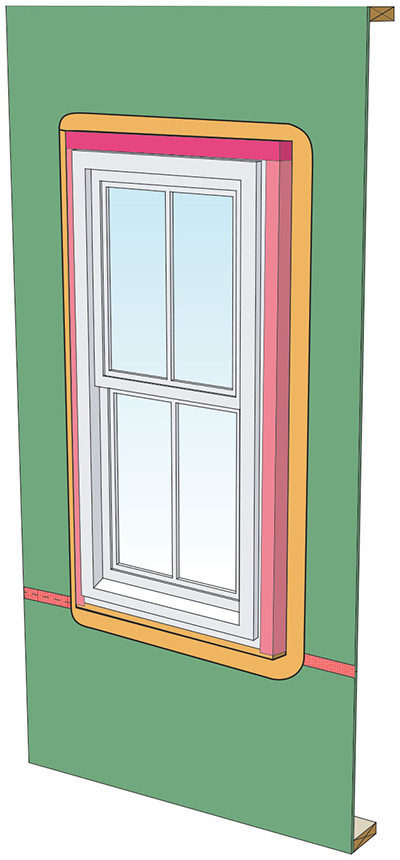

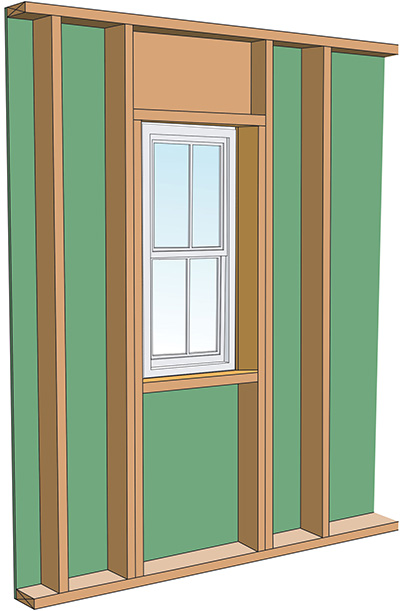

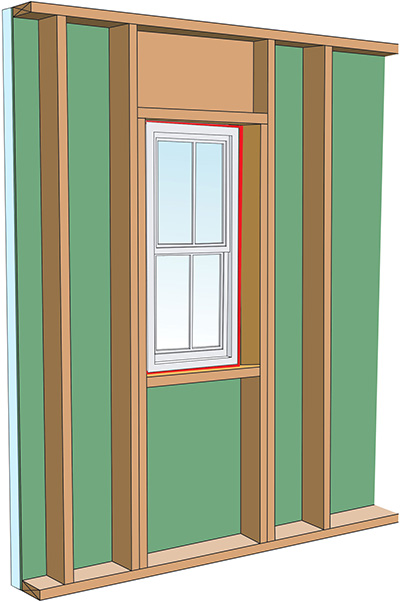

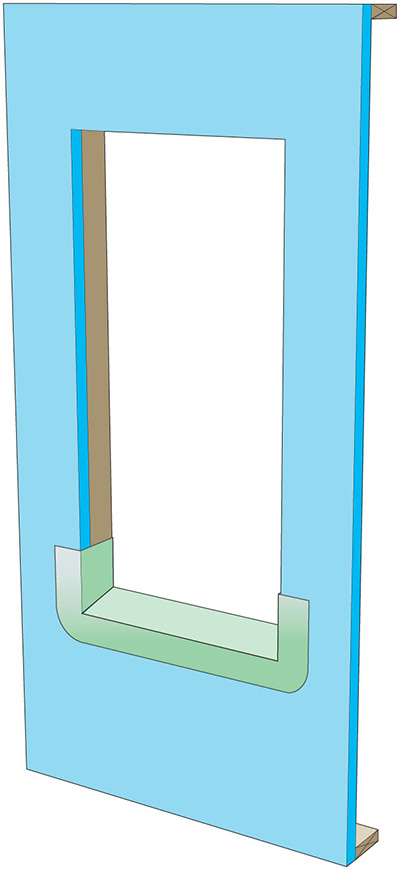

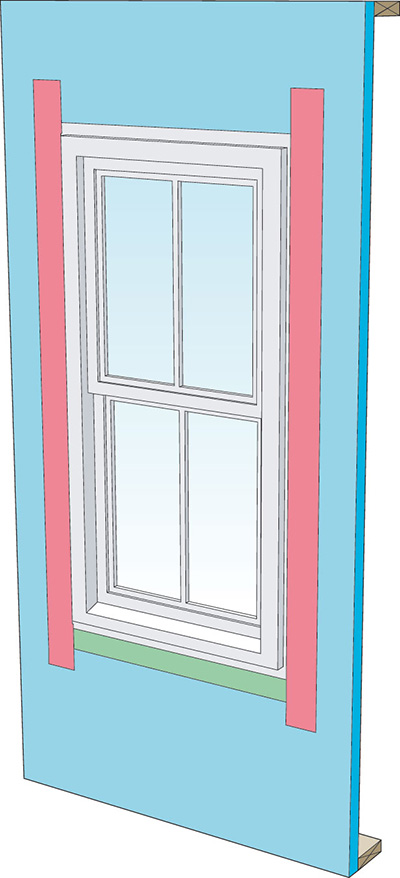

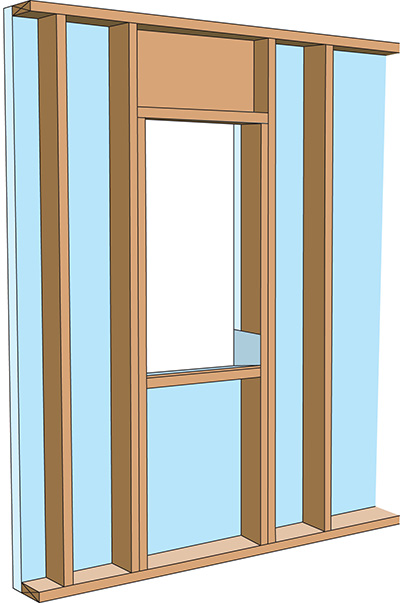

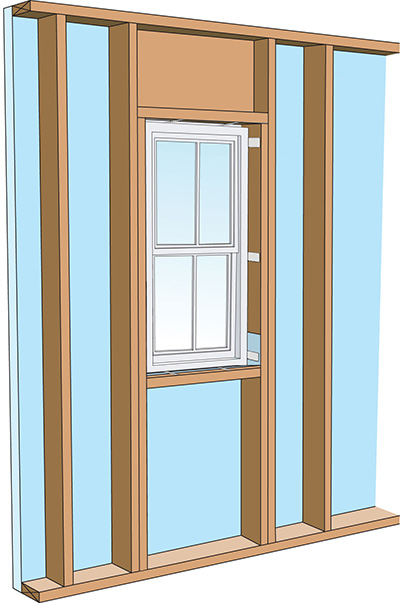

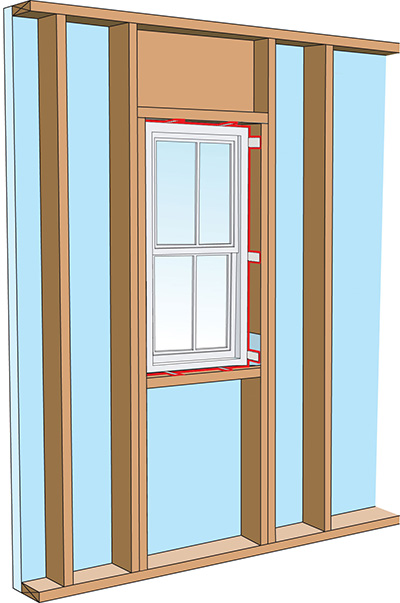

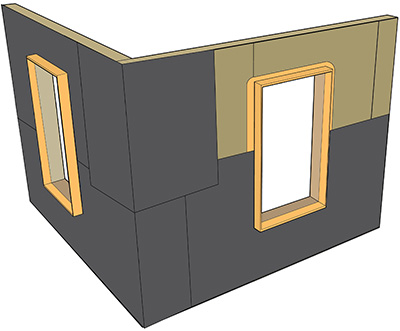

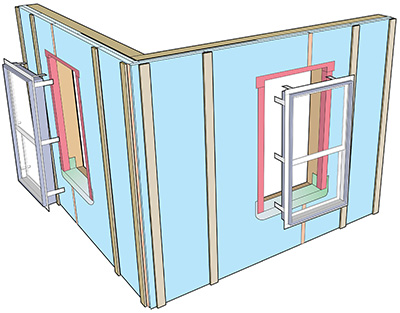

Figure 1 illustrates bump outs and foam sheathing. Figure 2 illustrates typical window installation with foam sheathing.

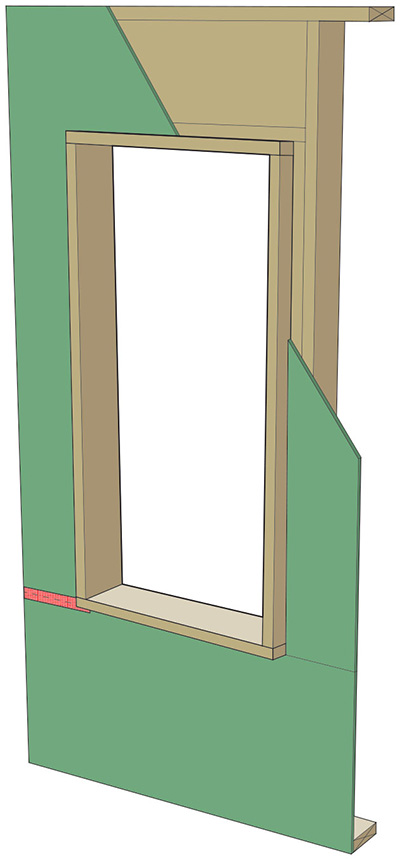

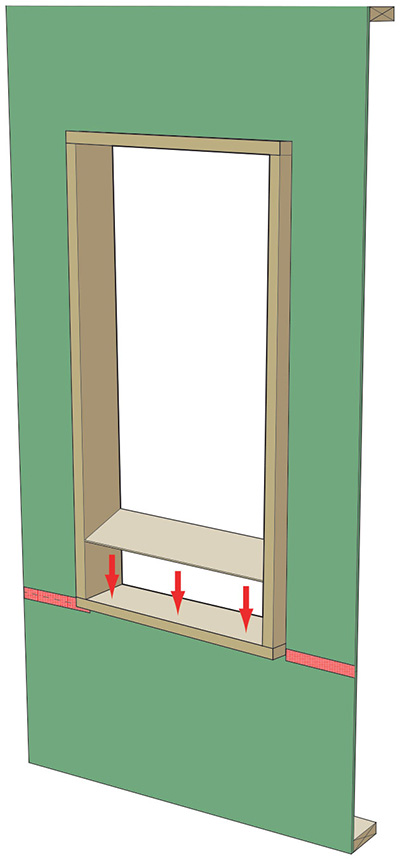

Figure 1 – Window Installation Sequence For “Bump Outs” And Foam Sheathing - The water and air control layer is the sheathing behind the continuous insulation. Note the “bump out” at the perimeter of the rough opening. Note the sloping sill. Note that the pan flashing can be liquid applied or a formable membrane. Note that the seams in the continuous insulation do not need to be sealed or taped.

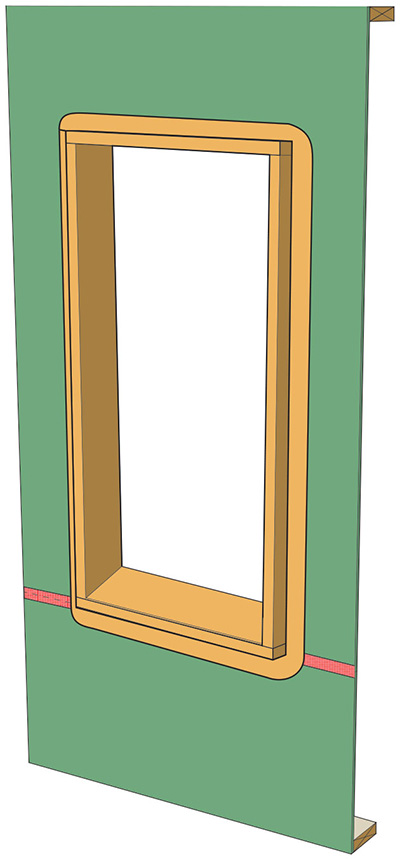

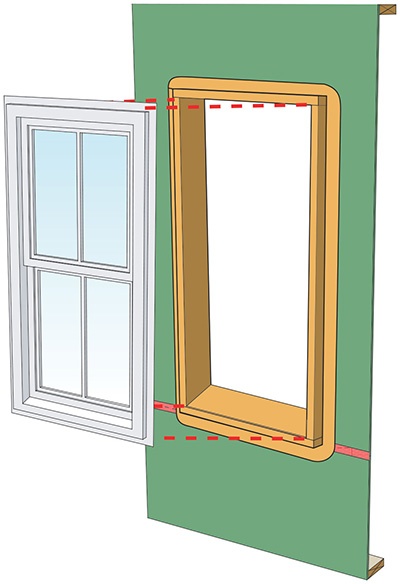

Figure 2 – Window Installation Sequence For Typical Foam Sheathing - The water and air control layer is the face of the continuous insulation. Note that the water control of the flanged window lines up with the water control of the face of the continuous insulation. Again note the sloping sill and that the pan flashing can be liquid applied or a formable membrane. Again note that sealant is not necessary behind the window flanges. And finally note that there is no wood behind the window flange – you don’t need any – the flange is seated directly over the continuous insulation – you attach the window to the framing with straps.

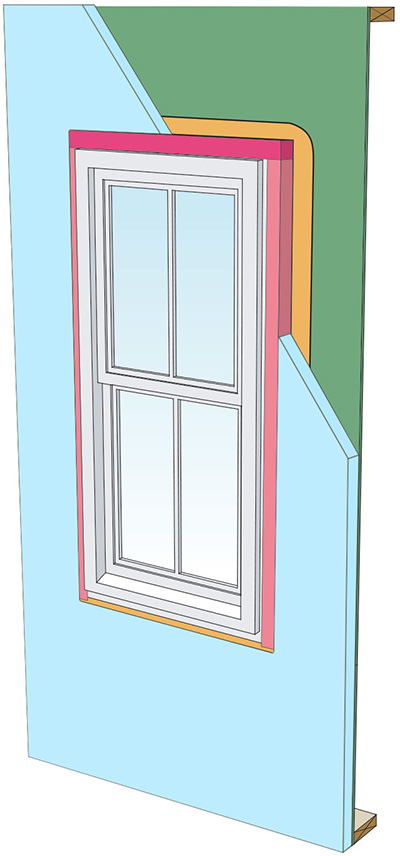

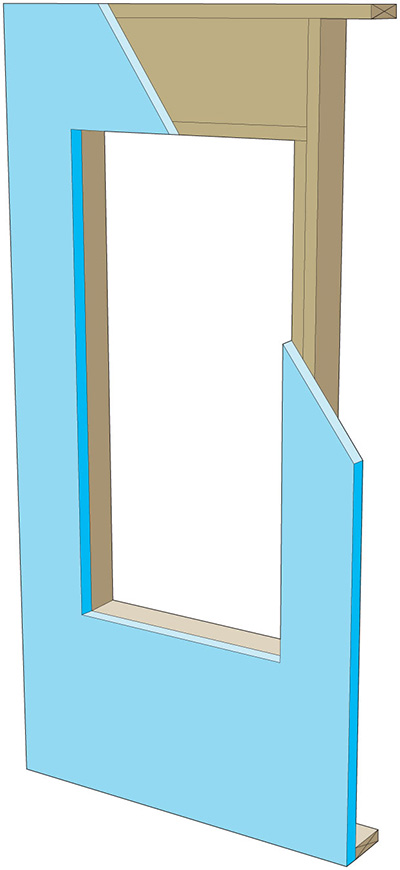

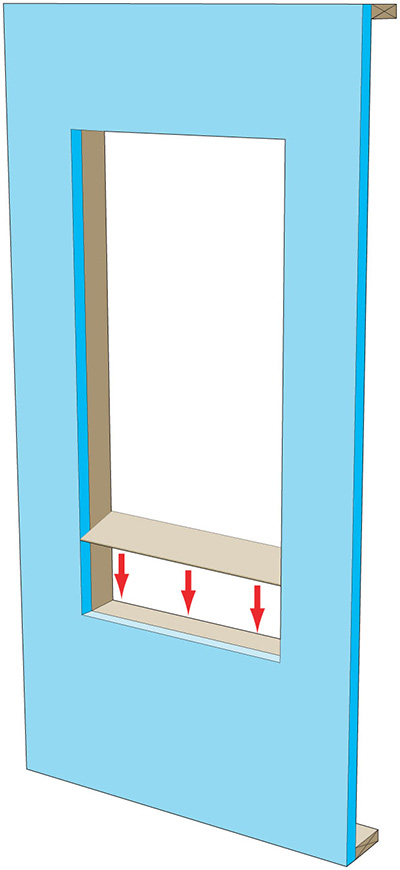

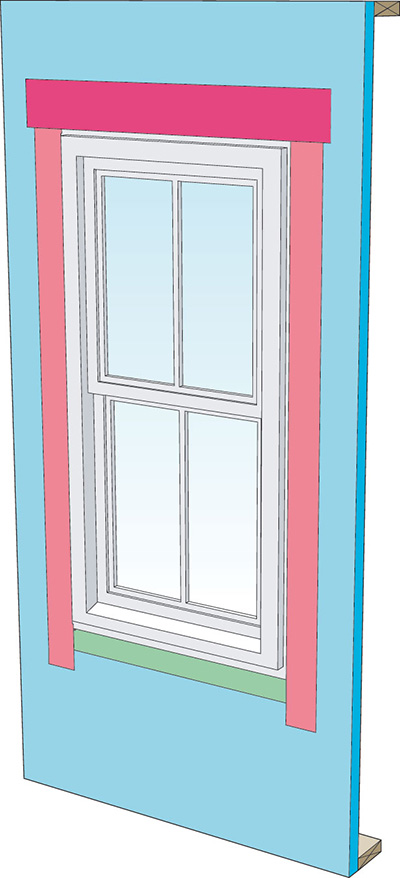

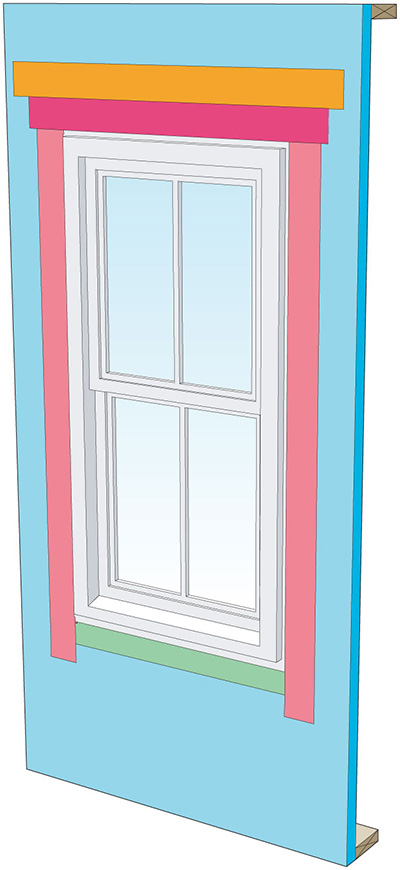

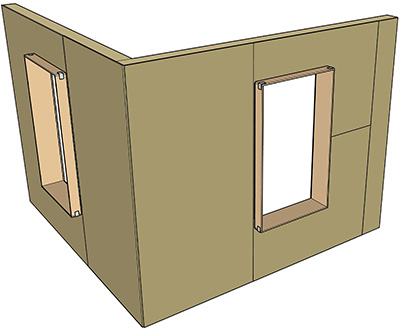

The NIST Net Zero Energy house in Gaithersburg, MD is one example (“BSI-081: Zeroing In – Net Zero Houses”, October 2014). See Photograph 8 and Photograph 9. In similar wall assemblies with 4 to 6 inches of continuous exterior insulation we line the opening with plywood or OSB “bumped out” the thickness of the continuous insulation (Figure 3). The “bump out” is “water proofed” with fluid applied flashing and integrated with a fully adhered membrane on the structural sheathing (Figure 4). A flanged window with straps is installed into the opening (Figure 5). In this case the “bump out” is an insignificant thermal bridge. The straps with the flanged window makes it all work.

Photograph 8 – Net Zero House Strapped Windows - We regularly use straps with flanged windows for ultra-high performance wall assemblies. The NIST Net Zero Energy house in Gaithersburg, MD is one example (“BSI-081: Zeroing In – Net Zero Houses”, October 2014).

Photograph 9 - More Net Zero House Strapped Windows – The wall assembly has 4 inches of continuous exterior insulation. The window opening is lined with plywood or OSB “bumped out” the thickness of the continuous insulation. Note the air sealing around the straps.

Figure 3 – Ultra-High Performance Wall – With 4 to 6 inches of continuous exterior insulation we line the window or door opening with plywood or OSB “bumped out” the thickness of the continuous insulation. Figure 4 – Ultra-High Performance Wall Continued - The “bump out” is “water proofed” with fluid applied flashing and integrated with a fully adhered membrane on the structural sheathing. Figure 5 – Ultra-High Performance Wall Done - A flanged window with straps is installed into the opening. In this case the “bump out” is an insignificant thermal bridge. The straps with the flanged window makes it all work. Easy peasy.

It should not be a tragedy when flanged windows and foam plastic insulating sheathing are used together. The feuding families need to get reconciled. High performance windows need continuous insulation and continuous insulation needs high performance windows.

[1] Apologies to William Shakespeare and Gertrude Stein. “Rose is a rose is a rose is a rose” comes from the 1913 poem “Sacred Emily” written by Gertrude Stein. “A rose by any other name would smell as sweet” comes from William Shakespeare’s play Romeo and Juliet. Recall that Romeo is from the house of Montague and Juliet is from the house of Capulet. It can be argued that the Montagues and Capulets were the Elizabethan version of the Hatfield’s and McCoy’s. Note that the Hatfield’s and McCoy’s intermarried and regularly changed allegiances. On a completely unrelated topic Fortune Magazine announced the merger of Dow Chemical and DuPont on December 11, 2015.

[2] Frank Zappa and the Mothers of Invention were performing at the Montreux Casino when a fire broke out due to a flare gun causing the roof to catch fire and inspired Deep Purple’s “Smoke on the Water”. In case you are wondering the opening riff is from guitarist Richie Blackmore.