Project Team: Catholic Charities Operation Helping Hands, Building Science Corporation, Louisiana State University AgCenter, Portland Community College, Sustainable Architecture LLC and many volunteers

Location: New Orleans, Louisiana

Description: 1,944 ft2 4 bedroom, two bath, one-story single family home

Completion Date: May 2010

Estimated Annual Energy Savings: $2,029 per year (57% energy use reduction compared to the Building America Benchmark)

Project Website: www.greendream2.posterous.com

Overview

The Green Dream 2 is a single-family home built on the site of a hurricane-damaged house that stood for 3 years before being demolished by the city of New Orleans. Staff and students from Portland Community College met the homeowner and his family on a trip to New Orleans and wanted to help them by building a new home; one that would be durable, healthy, comfortable, energy-efficient and affordable. Portland Community College connected the homeowner with Catholic Charities Operation Helping Hands who, in turn, asked BSC and the LSU AgCenter to be a part of the team.

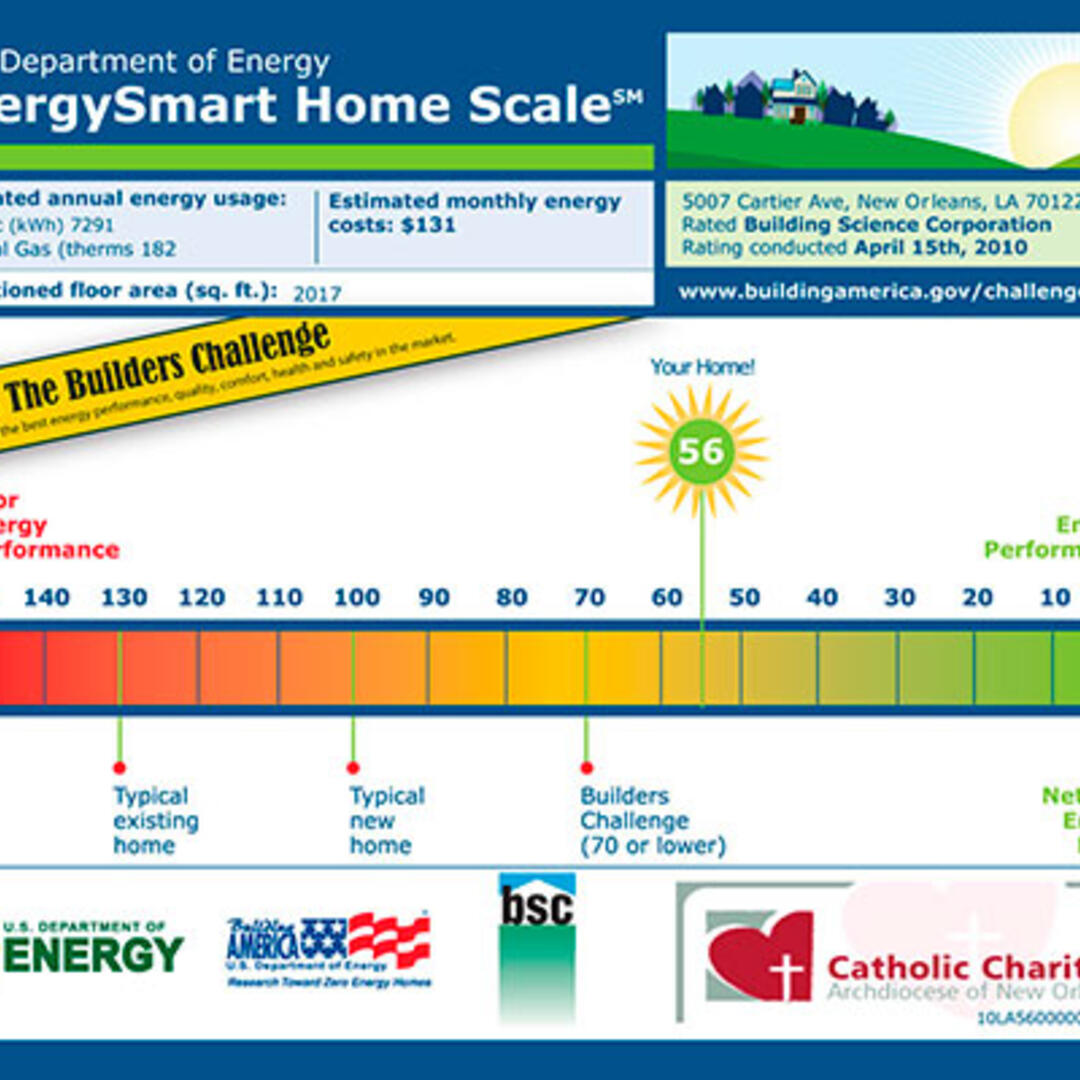

Architects and engineers at BSC created the plans and specifications for the 4-bedroom, 2-full bath, 1,944 ft2 house. As designed, the home will achieve a 57% energy use reduction when compared to the Building America Benchmark house. This 57% energy use reduction is equal to a HERS score of 56 and an estimated $2,029 annual utility bill cost savings to the homeowner.

Not only is the Green Dream 2 energy-efficient, but it is durable as well. Designed to withstand 130 mph winds and built with flood-recoverable materials, the home will serve as an example of high-performance construction in a hot-humid climate.

Design

The parametric chart above shows enclosure and mechanical upgrades specified for Green Dream 2 in order to achieve the goal of a 50% energy use reduction when compared to the Building America Benchmark house. In order for the house to be flood-recoverable, another important goal of the project, insulation materials were chosen that would not be damaged in a flood and would be able to be cleaned in place after a flooding event; both spray foam insulation and polyisocyanurate insulating sheathing have these characteristics. The windows installed in the house have both a low solar heat gain coefficient (SHGC) to reduce the amount of solar heat gain into the house, and an impact rating which prevents the glass from shattering and protects the interior from wind-borne debris during a hurricane.

All ductwork and mechanical equipment for Green Dream 2 is located in the unvented conditioned attic. Ductwork is sealed with mastic and caulked to ceiling drywall to prevent duct leakage and ensure air flows to rooms in the house are as designed to create a comfortable living environment.

In addition to heating, cooling and ventilation, Green Dream 2 is also equipped with supplemental dehumidification, a dehumidifier located in the attic with dedicated ductwork pulling air from the living space and supplying dehumidified air to the supply plenum.

Builders Challenge Certificate

Enclosure Design

Roof Assembly: Truss-framed unvented attic with R-30 roof insulation: 7” medium-density (0.8 pcf) open cell spray foam below roof sheathing, 5/8” treated plywood roof sheathing, fully-adhered roof membrane, high wind-rated asphalt shingles installed over the trusses, ½” paperless drywall installed below trusses.

Unvented attic with open cell spray foam

Wall Assembly: 2x4 treated walls at 16” o.c. with R-13 wall insulation: stud bays left open, ½” treated plywood, housewrap, 2” foil-faced polyisocyanurate insulating sheathing, ¾” treated furring strips and fiber cement siding installed on outside face of studs, ½” paperless drywall installed on inside face of studs.

Foil-faced polyisocyanurate insulating sheathing

Window Specifications: Showcase Custom Vinyl Windows and Doors single-hung, double pane, spectrally selective, impact rated Low-E: U=0.40, SHGC=0.21.

Air Sealing: Maximum 2.5 in2 leakage area per 100 ft2 of enclosure area. Critical seal air sealing approach with spray foam in both roof and floor assemblies and airtight drywall approach used in wall assembly. Adhesives and sealants used between framing members, around windows and doors, and at all mechanical and electrical penetrations through the enclosure.

Air sealing between framing membranes

Foundation and Floor Assembly: Wood pile, concrete grade beam and adjustable pier foundation, treated joist-framed floor on treated sill beam with R-15 floor insulation: 2.5” high-density (2.0 pcf) closed cell spray foam between floor joists, ½” fiber cement protection board installed below floor joists.

Pier foundation

Mechanical Design

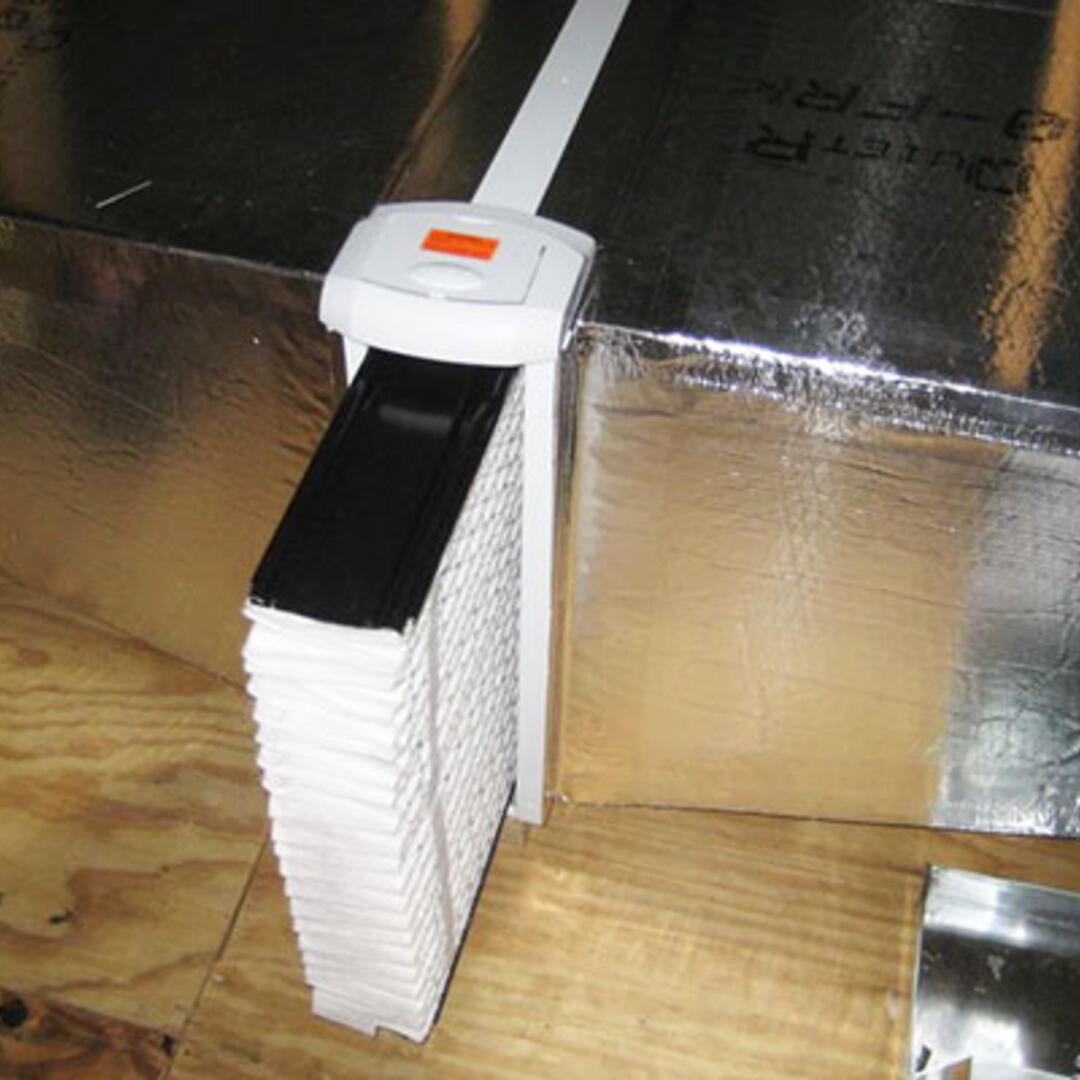

Heating, Cooling and Dehumidification: 9.0 HSPF/15.5 SEER air source heat pump split system with supplemental whole house dehumidification. Interior unit installed in conditioned attic with MERV 13 filter.

Ventilation: Central fan-integrated with supply only ventilation system controlled with built-in controls in dehumidifier. Outside air ducted to the return side of the air handler including both motorized and manual dampers.

Local Exhaust Ventilation: Intermittent spot exhaust provided in bathrooms and kitchen.

Space Conditioning Distribution: Air handler with sheet metal plenums and R-6 duct board supply trunk and R-6 flex duct run-outs installed in conditioned space. Ducted central return, dehumidifier return and transfer grilles above bedroom doors.

Duct board supply trunk and run-outs

Controls: Programmable heat pump thermostat and Aprilaire Model 70 Living Space Control.

DHW: 0.82 EF gas tankless water heater.

Construction

Construction began in June 2009 with the driving of the wood piles for the foundation. Concrete grade beams were poured over the piles and telescoping concrete piers were set on the grade beams. On top of this foundation, both borate pressure treated and ACQ pressure treated wood was used to frame the house and porches. Throughout the construction, a Catholic Charities site supervisor instructed volunteers, participated in weekly conference calls and worked through details with the project team. This level of commitment and coordination ensured that critical design details were carried out in the field.

Once the housewrap was in place on the treated plywood, the project team held a window installation demonstration for volunteers and industry professionals. The window installation sequence from the drawing set was followed step by step as project team members assisted volunteers in installing Green Dream 2’s sixteen windows.

Both pre-construction and pre-MEP installation meetings were held with the HVAC installer, plumber, and electrician to ensure each trade understood how their work contributed to achieving the project’s goals.

Testing

During the design phase of the project, performance goals for overall house airtightness and duct leakage were set for Green Dream 2. While construction was wrapping up, BSC performed both a blower door test and a Duct Blaster® test to find out if the goals were met.

BSC’s maximum air leakage target is 2.5 in2 per 100 ft2 of enclosure area. For Green Dream 2, this is equal to 1590 CFM 50. When tested, the air leakage was 1123 CFM 50, well below the maximum CFM 50, meeting our set goal. BSC’s performance target for total duct leakage is 10% of total system CFM while the performance target for duct leakage to outside is 5% of total system CFM. Green Dream 2 has a 2-ton system installed, equal to 800 total system CFM (400 CFM per ton).

Results from the Duct Blaster® showed no measurable duct leakage to outside and only 50 CFM total duct leakage. Both results greatly surpass the targets of 40 CFM duct leakage to outside and 80 CFM total duct leakage. In addition to the Duct Blaster® and blower door tests, room by room air flows were tested using a flow hood and all found to be as designed.

Moving Forward

BSC is planning on collecting monthly gas and electricity bills from the homeowner for at least a year. Actual energy use will then be compared to predicted energy use.

Design Highlight: High-Wind Connectors, the Prescriptive Path |