Project Team: Coastal Habitats, Building Science Corporation

Location: Hilton Head, South Carolina

Description: 1,495 ft2 one-and-a-half story, three-bedroom, three bath single family house

Completion Date: September 2008

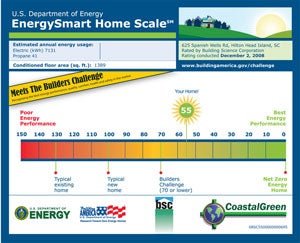

Estimated Annual Energy Savings: $426 per year with 50% source energy savings; with 6.5 kW PV array predicted source energy savings is 99%

Overview1

Primarily as a resort location, Hilton Head Island has a somewhat different residential housing market than other more traditional areas. The market is made up of both year-round occupancy and seasonal occupancy, and the size and cost of new homes range from the very large and expensive to those of more normal size but still higher cost. Most houses are simply “built to code.” High performance and “green” housing practices have not begun to penetrate the market.

As part of the U.S. Department of Energy’s Building America Program, a partnership was developed with a builder who had learned from experience that just building to code left a lot to be desired from an overall performance perspective. He came to believe that real value lies in implementing building science principals within a systems engineering approach to high-performance housing.

The whole-house performance approach described here builds a framework of understanding that starts with principals that lead to evaluation of options that leads to a coherent plan that leads to quality execution of producing high-performance homes.

High-performance homes are comfortable, healthy, safe, durable, energy efficient, and respecting of the environment. A high-performance home will also reduce a builder’s risk of warranty/service call-back and customer complaint, leaving more room for profitability.

The homes were finished with bamboo or cork flooring and recycled carpet and pad. The open cell spray foam insulation was soy based. Finger jointed interior wood trim was used extensively throughout the homes. Porch decks were of recycled synthetic decking materials. Where possible, a product manufacturer’s dedication to the environment was a consideration in making product selections.

Low volume dual flush toilets using half the water of regular toilets were used throughout, potentially saving a typical family up to 7,000 gallons of water annually. Each home is fitted with gutters and downspouts to control water runoff. A rain barrel for each home will be used to collect water for watering flowers and shrubs.

Builders Challenge Certificate

Marketability

In addition to the normal marketing strategies, a community web site was developed to provide important education along with advertising. Another successful effort was establishing a green building task force within the local homebuilders association to raise awareness among builders.

The fact remains that building a high performance house simply costs more. Further, these houses were built with the “less is more” mindset meaning less square footage but greater value than typically found. That translates directly to higher asking sales prices per square foot. In a market that is so realtor driven, it can be incredibly difficult to deal with the “how much per square foot” question. The answer was to bring the focus back on the benefits of the energy efficiency and indoor air quality built into the homes. While some potential buyers came because of the green aspects of the homes, most were not familiar with the concepts. However, once they became informed, they were typically more receptive to the asking prices.

Local realtors were a bit cold to the concept primarily because most just couldn’t grasp this new way of thinking. Those that were interested in the environment and green building have become great allies. Additionally, the local newspaper and print media have been big fans of the project and have run various articles at different stages of development.

At the end of the day when buyers became educated, the higher cost became less of a deterrent.

From the developer’s viewpoint, the feeling prevails that the right thing was done with this project. In an increasingly competitive market, the product offered stands out among the masses showing a better way. There are no other homes in the local marketplace that compare in terms of indoor air quality, energy efficiency, and build quality. This type of product appraises at higher values, costs less to operate, and provides a more comfortable and healthy environment for living. That reduces a builder’s risk and gives a competitive edge. The additional costs and efforts to obtain the high levels of performance and indoor air quality were well worthwhile. The mechanical subcontractor, in particular, has developed a new understanding and appreciation for the importance of proper design. The lessons learned have allowed them to implement some of these best practices into their other custom and tract projects. From a public good point of view, that’s the real goal, to cultivate best practices that lead the way toward sustainable energy efficiency and energy independence without unwanted side effects.

Enclosure Design

Roof: Unvented

Foundation: 4” monolithic slab with turned-down edges poured over a 6-mil polyethylene vapor barrier over compacted stone/sand; slab-edge insulation was not used due to the long-term risk of termite infestation through or behind the insulation.

Framing: 2x6 wood frame walls

Air Sealing: Insulated headers were used in conjunction with other advanced framing techniques at corners and partition intersections to reduce unnecessary wood and increase insulation; foam gasket and capillary break between the pressure treated bottom plate and the foundation.

Roof Insulation: R-30 open cell spray foam in cathedralized attic or cathedral ceiling

Wall Insulation: R-21 open cell spray foam cavity insulation with 1/2” XPS foam sheathing

Drainage Plane: Butyl flashing membranes integrated with the house wrap drainage layer for all windows, doors, roof-to-wall flashings and through-wall penetrations for plumbing, venting, and wiring.

Roof-to-wall (kick-out) flashing

Window Specifications: U=0.33, SHGC=0.32

Infiltration: 2.5 in2 leakage area per 100 ft2 envelope

Features:

The site is a four-acre parcel with nearly two acres of freshwater wetlands that will remain undeveloped

Mature trees around the homes were left in place as much as possible to help shade the homes in summer

Climate Specific Details:

Having a high priority for comfort at low cost in hot-humid climates requires, in order of priority for walls:

glazing with low solar heat gain;

air sealing;

opaque areas with moderately high thermal insulation; and

glazing with thermal resistance at least high enough to avoid wintertime condensation.

Having a high priority for durability in hot-humid climates requires:2

a continuous water drainage layer behind the cladding, integrated with window, door, roof, and other penetration flashings, to protect water sensitive materials located deeper in the assembly;

a capillary suction break between foundation materials in soil contact and walls above;

water vapor diffusion resistance between water absorptive claddings and wall sheathing to retard moisture movement driven by solar heat; and

interior finish materials that do not retard water vapor movement to allow drying to the inside air.

Water Management

Landscape Plan: Low maintenance grasses and shrubs were purposefully designed into the landscape; all hard surfaces are pervious concrete.

Mechanical Design

HERS Index Score: 59 without solar hot water (SDHW); 55 with SDHW

Heating: 1.5/2.0 ton 8.05 HSPF air source heat pump

Cooling: 15.1 SEER

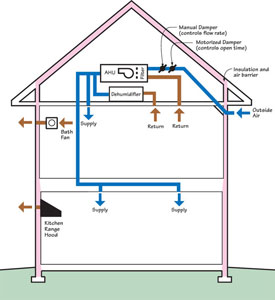

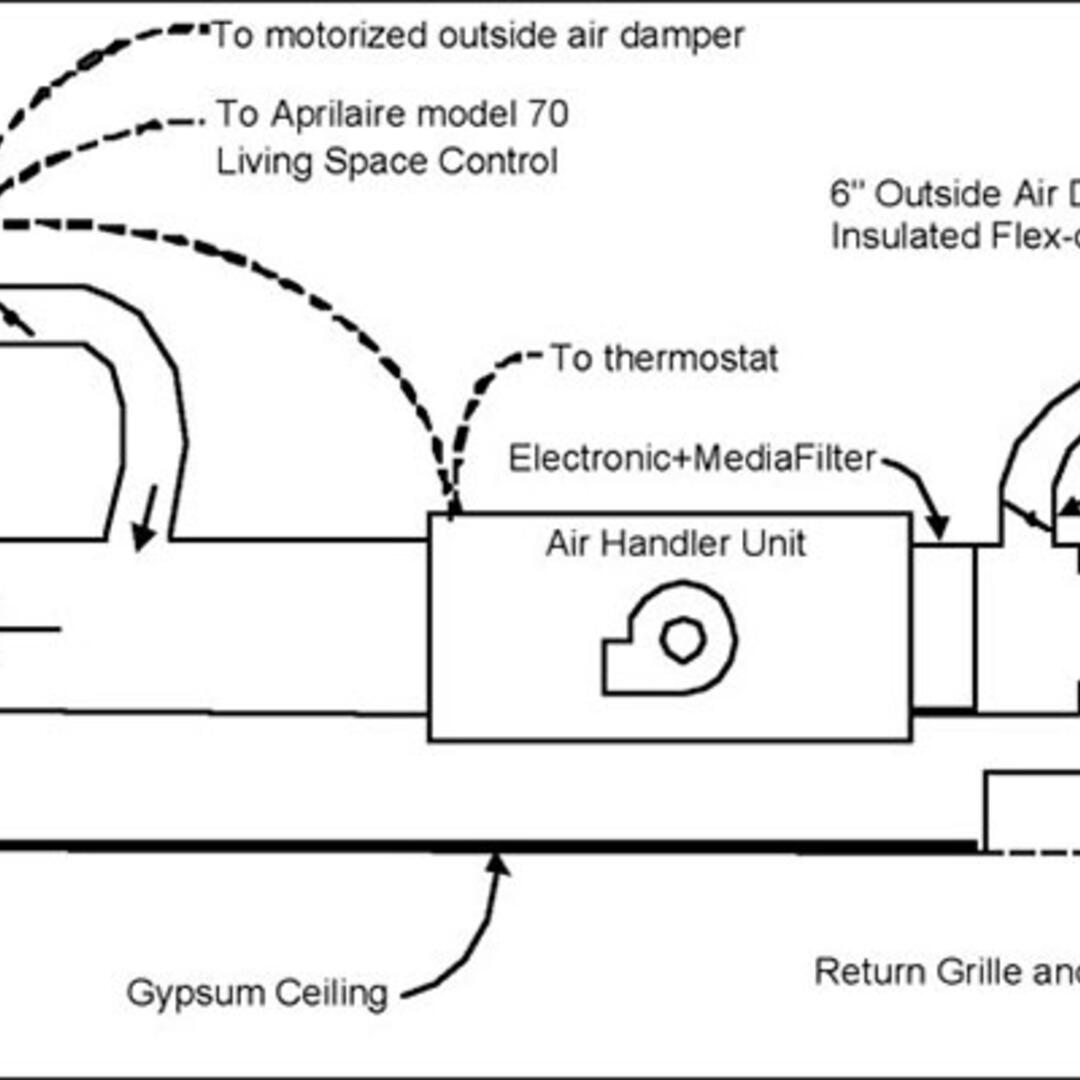

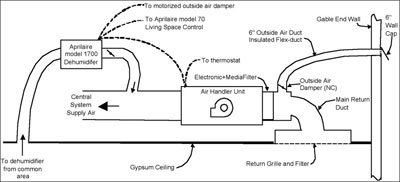

Ventilation: Central-fan-integrated supply (CFIS) with fan cycling and motorized damper

Dehumidification: Whole-house dehumidifier integrated with central system

Dehumidification system schematic

Return Pathways: Transfer grilles/jump ducts at bedrooms

Ducts: In conditioned attic space

DHW: Sealed-combustion, direct vent tankless DHW; 0.85 EF; solar hot water optional

Direct vent tankless domestic hot water heater

Optional solar hot water panels

Appliances: Energy Star dishwasher, refrigerator, range, clothes washer, clothes dryer

Lighting: 100% CFLs

Ventilation

In this project, a 6 inch diameter insulated outside air duct and normally-closed motorized damper were fitted to the return side of the air handler unit generally according to the schematic.3 The system supplies about 50 cfm of outside air for a minimum and maximum of 33% of the time. This fan cycle rate will not provide the ASHRAE Standard 62.2 (ASHRAE 2007) airflow amount, although the system could meet the 62.2 airflow amount if the fan was operated continuously. Operating the central fan continuously is NOT recommended, especially in warm-humid climates, because of re-evaporation of moisture from the wet cooling coiling4 and excessive fan energy consumption which ends up as heat that the cooling system must remove. As was done in this project, the best practice is to install one 62.2 compliant exhaust fan in every house, which is the ventilation system of record for rating purposes. The existence of that fan exhaust fan, and an on/off switch, meets the 62.2 requirements by itself. Central fan cycling operation is then outside of the rating in the same way that the Fan On button on the thermostat is outside of the rating. In reality, about half the fan cycling operation for supply ventilation does double-duty because it is needed for thermal comfort mixing anyway.

The ventilation controls for this particular system are integrated with the whole-house dehumidifier controls. Here are the principals of operation:

a) The dehumidifier must be have power in order for any ventilation and central fan cycling and outside air damper cycling to occur. The dehumidifier will operate to reduce indoor humidity independently of ventilation and central fan cycling.

b) The central fan will operate for at least 10 minutes per half hour (including any operation due to thermostat demand).

c) The outside air damper will be open for 10 minutes per half hour while the central fan is operating.

The outside air damper will not be open for more than 10 minutes per half hour regardless of any additional fan runtime due to thermostat demand. The outside air fraction is about 10% or less, so, being mixed with 90% or more inside air, there is no need to dehumidify it first. The moisture will be removed with normal cooling demand, or by the dehumidifier if cooling demand does not control it.

d) The dehumidifier will run only as needed based on the measured humidity in the living space and the humidity setpoint. As humidity rises in the living space for any reason, ventilation or otherwise, the dehumidifier will be energized and bring the humidity back down.

Air filtration was handled in all the homes using a combination electronic plus wide media air filtration product. Filtration efficiency was 98% to 99% for large particles (1 micron and larger) and 94% for small particles down to 0.35 microns.

Quality Assurance & Quality Control

Before even becoming involved with the USDOE Building America program, the builder had decided to build the first community on Hilton Head Island with Earthcraft House certification. Every home was certified as both Earthcraft House and ENERGY STAR®. In order to achieve this status, independent third-party inspections were required. At the start of the project, a plan review was completed and a HERS rating estimated based on specifications. A pre-drywall inspection was completed as were blower door and duct blast tests for each home.

As the project progressed, the builder had a dedicated employee that was onsite every day to coordinate work between sub-contractors, improving communication, and keeping attentive to quality issues before they got out of hand.

System Testing

Testing of building enclosure leakage, duct leakage, room pressurization, and room air flow was completed to verify whether these important factors met the design criteria described above.

All of the houses except one met or exceeded the maximum leakage criterion.

All of the duct systems had little to no duct leakage to outside, meeting the design criteria. Even though the entire air distribution system (ducts and air handler) was inside conditioned space, reducing total leakage is important in order to assure that the air gets to where it was intended to go to meet the space conditioning load.

Room air flows all fell within a functional range of the design values with the supply registers fully open. Some re-balancing of supply registers may be expected according to occupants use and desires.

Monitoring

Prototype home is instrumented. When home is occupied, monitoring can begin.

Lessons Learned & Future Projects All of the houses except one met or exceeded the maximum leakage criterion. The Molly #8 house did not meet it because of an insulation/air sealing defect in the roof. An HVAC duct in tight quarters blocked the insulators path to do the job right, so it was just left that way. The insulator should have notified the builder of the problem. If testing had not been part of the process, that defect would been unnoticed until it may have created a moisture problem. Of the three houses ready for testing, all rooms were pressurized less than 3 Pa, except one room which was 9 Pa. This was due to a combination of a little too much air going to that room, a 1/4” door undercut instead of 1/2”, and a transfer duct that wasn’t working as well as intended. All of these factors can be fixed. Technology Gaps & Barriers |

Footnotes

Rudd, A., Feldman, H. 2007. “Introducing the market to high-performance green building on Hilton Head Island.” Journal/Conference Paper submitted to Midwest Research Institute/NREL/USDOE, Golden, CO, under contract no. KAAX-3-32443-10.

Lstiburek, J. 2005. “Builder’s Guide to Hot-Humid Climates.” ISBN 0-9755127-3-0, Building Science Press, www.buildingsciencepress.com.

Rudd, Armin, and Joseph Lstiburek, 2008. “Systems Research on Residential Ventilation.” Proceedings of the 2008 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, California, August. American Council for an Energy Efficient Economy, Washington, D.C.

Henderson, H. Jr., Shirey, D. III, Raustad, R. 2007. “Closing the Gap: Getting Full Performance from Residential Central Air Conditioners; Task 4.1-Develop New Climate-Sensitive Air Conditioner Simulation Results and Cost Benefit Analysis.” National Association of State Energy Officials, Alexandria, VA, and New York State Energy Research and Development Authority, Albany, NY. April. http://www.cdhenergy.com/reports/STAC_Task4_Report_Apr27.pdf