Project Team: Shaw Construction, Bill Poss Architects, DHM Design, City of Aspen, Building Science Corporation

Location: Aspen, Colorado

Description: 180 affordable housing units in 38 multi-family buildings

Completion Date: December 2007

Estimated Annual Energy Savings: 43% savings over the Building America benchmark; $1,350 estimated average annual savings per unit

Overview

Aspen, Colorado has one of the most expensive real estate markets in the United States. The mountains around Aspen provide beautiful views, skiing, and small-town seclusion, but they also limit the space available for the city to grow. In 2000, the Aspen Area Community Plan called for affordable housing projects based on the goal of housing at least 60% of the city employees within the city limits. The Burlingame Ranch project is one major step towards achieving this goal.

In 2004 an architectural design competition was held to select a design/build team, and the Aspen city council selected the development team consisting of Shaw Construction, Bill Poss Architects, and DHM Design. This team’s design features a “ranch vernacular” style of architecture, and provides 236 units of condominium-style housing in approximately 30 buildings and 265,000 square feet of living area. Additional single-family home sites were sold to individuals. The development features a bus route to downtown (with stops less than 1/2 mile away), pedestrian and bike trails, and a commons building where a small market is available to eliminate the need for last-minute trips to the grocery store.

Energy Analysis

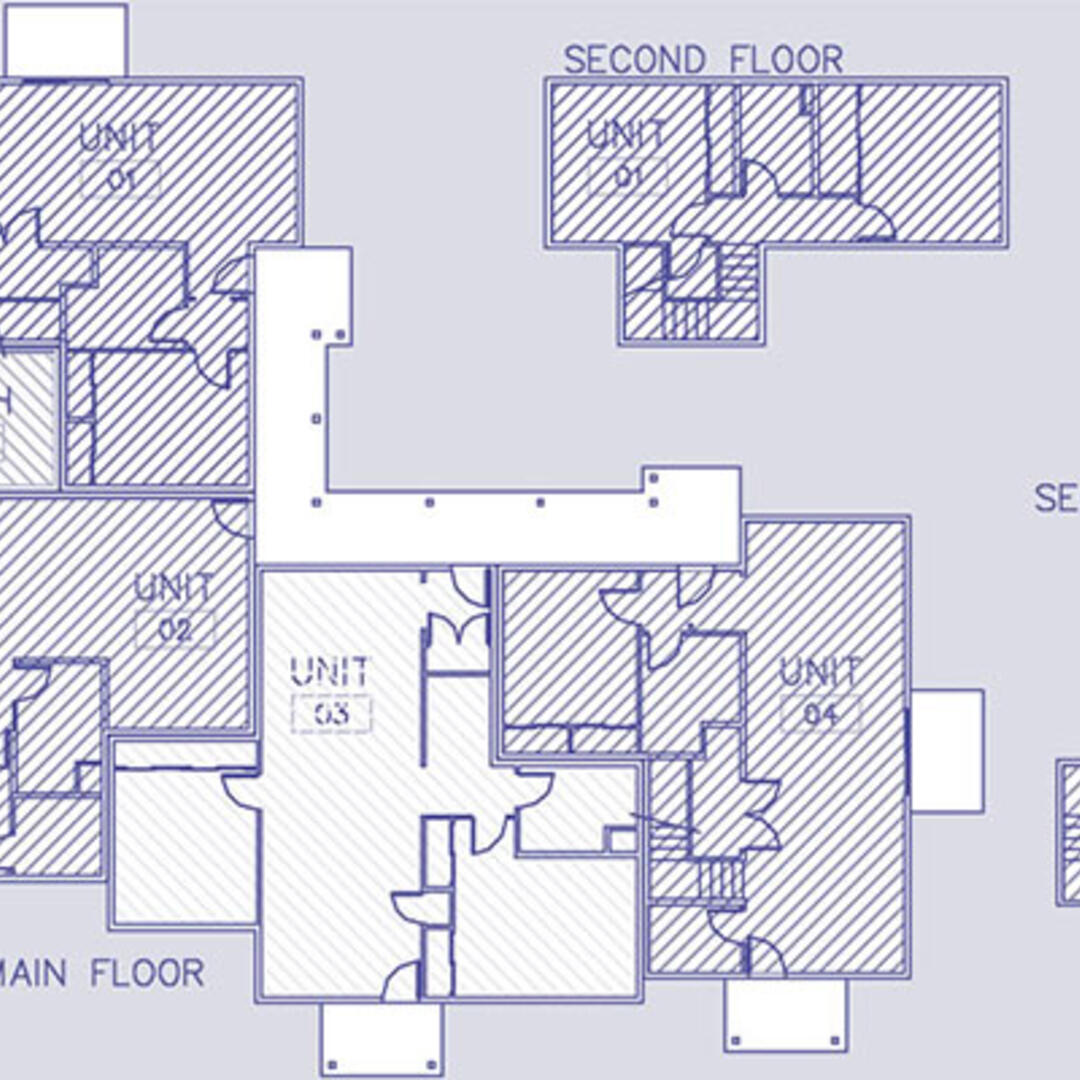

The Poss Architects proposal for the Burlingame project included ten different multifamily building designs. Each design has multiple minor variations from building to building. Building type F(1) was selected as a representative example of the building designs. Although the building designs are different, all fall into the same range of energy savings, since they have similar sizes and shapes and are built with the same attributes.

Description of Building F(1)

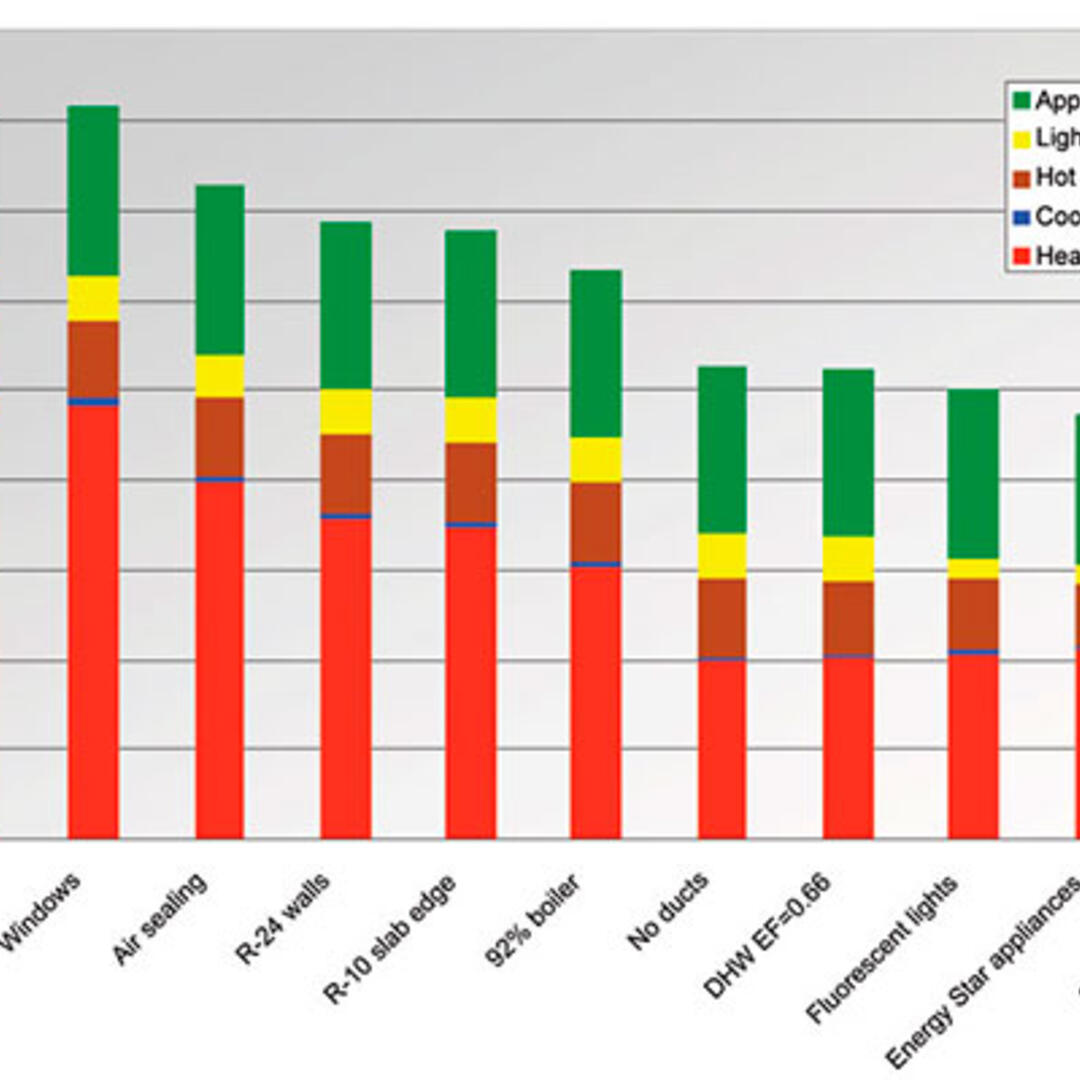

Building type F(1) includes four units: one 1-bedroom unit, one 2-bedroom unit, and two 3-bedroom units. The building includes about 5300 square feet of living space. Overall, the annual source energy savings was estimated to be between 43 and 51%, which corresponds to an annual energy cost savings of about $1350 per dwelling unit.

Energy and Building Science Consulting

In 2005 and 2006, BSC worked with the development team and the City of Aspen to design the energy efficiency measures, including high-density spray foam insulation; a tight envelope; 90+% furnaces; baseboard hot water radiators; efficient domestic hot-water systems including a solar hot water system; heat recovery ventilators; a fluorescent lighting package; and Energy Star appliances. In addition, BSC worked with the development team to review transition and correct details, finalize the solar hot water system design and the mechanical system design, review third-party energy code compliance reports, and provide support through the bulk of the construction phase.

In 2007, BSC continued to support the construction of Burlingame, and assisted in the short- and long-term monitoring by NREL of one of the buildings in the project. NREL and BSC personnel performed field testing on the F(1) building at Burlingame during the period of March 26-April 5, 2007, and BSC collaborated on a periodic basis with NREL to ensure that the NREL modeling and analysis reflected the systems actually installed in this project.

Quality Assurance

BSC performed the following quality assurance activities for the Burlingame project:

- Document review: wall assemblies, transition details, water management, central heating systems schematic, solar panel locations, specifications for appliances.

- On-site testing of each unit: blower door test of each unity by third-party tester.

- Intensive testing of mechanical, solar, and ventilation systems by NREL and BSC.

Current Status

Phase I of Burlingame Ranch was substantially complete in December 2007. Phase II of Burlingame Ranch is currently in the beginning stages. The City of Aspen has asked several design firms to provide designs that provide an option for increased density for Phase II. The City will select a firm and a density option in spring 2009, and design should be substantially complete by fall 2009. BSC will be part of Phase II of Burlingame in the same capacity as it was in Phase I.

Enclosure Design

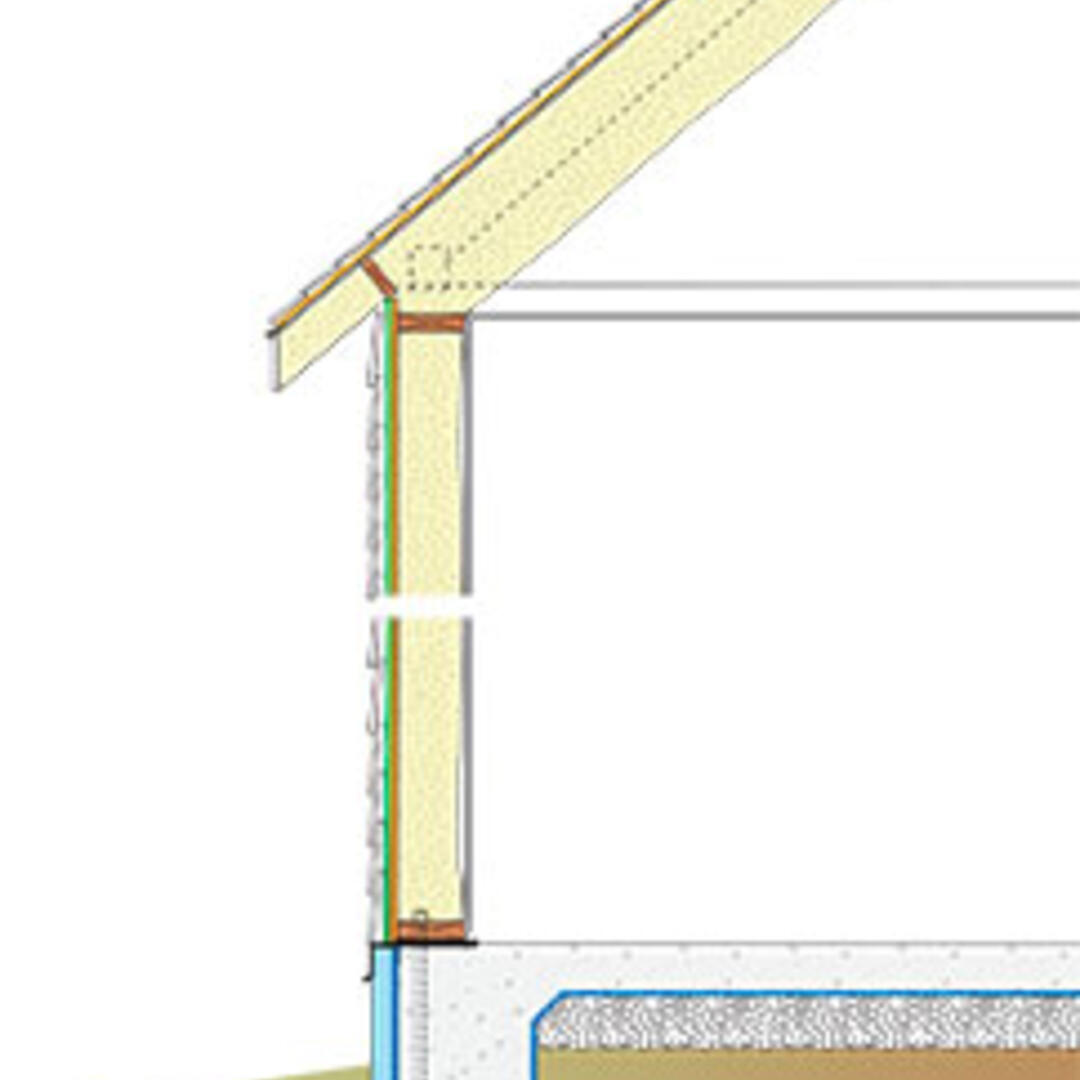

Roof: Unvented

Foundations: Foundations include slab-on-grade with perimeter insulation (shallow frost-protected design) and walk-out basements with polyisocyanurate insulation on the interior of the basement walls.

Shallow frost-protected foundation

Framing: 2x6 @24” o.c. advanced framed walls

Air Sealing: Spray foam insulation and low expanding foam sealant around windows.

Roof Insulation: R-50

Wall Insulation: R-24

Foundation Wall Insulation: R-13; 2” thick polyisocyanurate on interior of basement walls

Slab Edge Insulation: R-14; approximately 2” thick high-density spray foam, shallow frost-protected design

Drainage Plane: Building paper behind horizontal or vertical sheathing

Radon Protection: Passive system installed

Window Specifications: Vinyl frame, double glazed LoE

Infiltration: 2.5 in2 leakage area per 100 ft2 envelope

Mechanical Design

Heating: Hydronic baseboard system with 90% AFUE central boiler

Cooling: None

Ventilation: Continuous heat recovery ventilator (HRV) system in each dwelling unit

Ducts: None

DHW: Central solar system with boiler back-up, 192 ft2solar panel with 250 gallon tank; back-up boiler estimated EF=0.66.

Appliances: ENERGY STAR® dishwasher, refrigerator, clothes washer and ceiling fans.

Lighting: 90% ENERGY STAR® CFLs

Site Generated Power: 10 kW photovoltaic panel array (shared by all units in the community).

Water Management

Landscape Plan: Plan minimizes water run-off from the site

Plumbing Fixtures: Very high efficiency—faucets, showerheads and toilets

Lessons Learned From Phase I

Technology Gaps & Barriers

|