The Vancouver Test Hut Facility

The Vancouver Test Hut is a 900 square foot field testing facility located in Coquitlam, BC, on the rooftop of the two story commercial office building occupied by team member and builder, Gauvin 2000 Construction Ltd. The rooftop location was chosen because of the increased security offered by the controlled access through the building and for the unobstructed exposure to the elements in all directions. The test facility is designed to accommodate seven wall test panels on each cardinal direction (a total of 28 wall test panels) and three roof test panels on each of the north and south roof slopes (a total of 6 roof test panels).

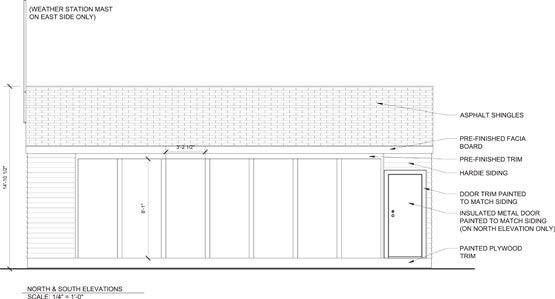

Figure 1: Vancouver Test Hut south elevation

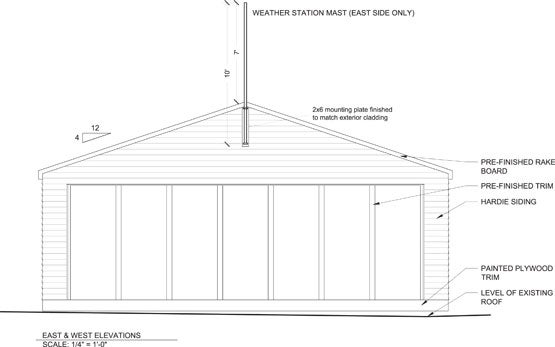

Figure 2: Vancouver Test Hut west elevation

Test Walls

The initial set of test walls was constructed to represent conventional construction practices from the past 40 years, to investigate the role of specific assembly layers, and to test possible solutions. These initial walls were deconstructed in 2009, following Phase II, in order to ensure that Phase III assemblies were not affected by prior test procedures. As well, deconstruction allowed for detailed observation of each assembly, in order to supplement and verify sensor data.

In Phase III, the emphasis was on analysis of assembly performance with wetting on the exterior of the sheathing. The walls used were similar to those constructed for the initial phases. Phase IV is focused on the performance of different variations on the exterior insulation approach. Testing conditions include intentional wetting of the sheathing from the interior and exterior.

For details about the test walls used to date, please see Vancouver Test Hut Phases I-III Wall Assemblies and Vancouver Test Hut Phase IV Wall Assemblies.

Monitoring and Control System

An integrated monitoring and control system measures and records performance data, controls interior temperature and humidity conditions, and is connected to the internet for remote monitoring and control.

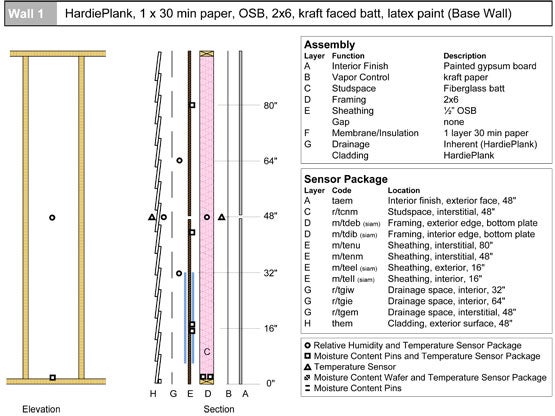

Figure 3: Typical instrumentation package

The monitoring system measures the indoor temperature and humidity and an instrumentation package in each test panel. The instrumentation package varies from panel to panel depending on construction and includes 16 to 20 sensors to monitor moisture content, temperature, and relative humidity at multiple locations in the test panel assembly (see Figure 3). The sensors are measured every 5 minutes and the average saved to memory every hour.

|

To collect weather data, a steel mast on the roof of the test facility supports a weather station at a height of 22 ft above the roof of the office building and 50 ft above ground level. The test hut’s monitoring system continuously collects the following data:

|

Figure 4: Test hut weather station |

Wetting Systems

|

Wetting systems installed in the test walls allow known amounts of water to be injected at controlled times and locations, simulating a window leak (interior wetting) or a leak in the rainwater control layer (exterior wetting). Test data following wetting events is used to help determine the drying potential of specific wall assemblies. The wetting apparatus consists of a storage media and a tube connecting the storage media to the interior of the test hut to enable wetting without opening the wall. During initial construction for Phase I, a wetting system was installed to inject water against the interior surface of the sheathing. For Phases III and IV, both interior and exterior wetting systems were installed. |

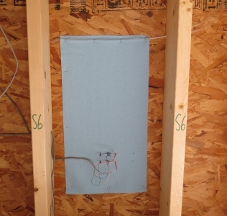

Figure 5: Interior wetting apparatus |