Good design and practice involve controlling the wetting of building assemblies from both the exterior and interior and different climates require different approaches.

Vapor Permeance Characteristics

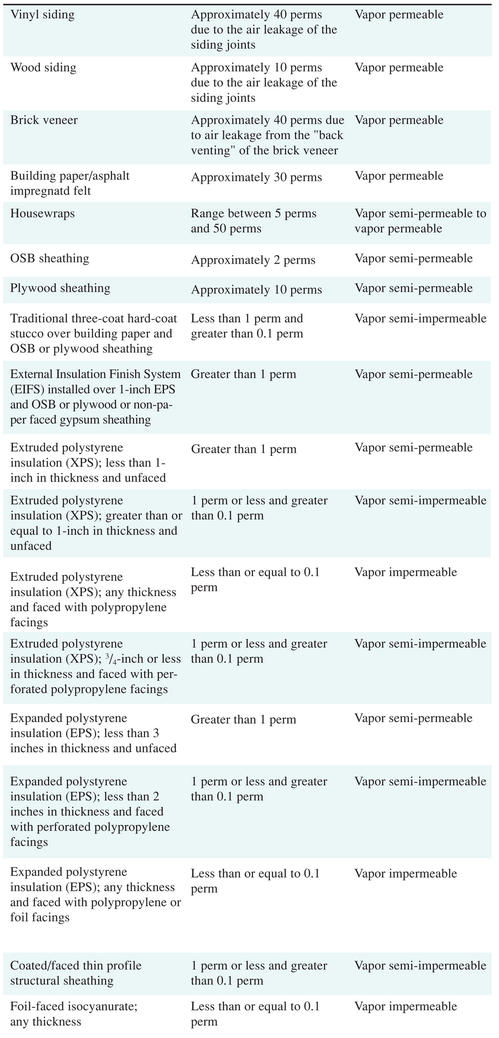

The vapor permeance characteristic of the sheathing/cladding assembly is defined by the effective wet cup permeance of both the cladding and sheathing combined. Four categories are established:

- Vapor impermeable: 0.1 perm or less

- Vapor semi-impermeable: 1.0 perm or less and greater than 0.1 perm

- Vapor semi-permeable: 10 perms or less and greater than 1.0 perm

- Vapor permeable: greater than 10 perms

For example, an assembly using foil-faced isocyanurate rigid insulation is classed as vapor impermeable regardless of the cladding type installed external to the foil-faced isocyanurate.

OSB sheathing and plywood sheathing covered with a building paper or housewrap and vinyl siding are classed as vapor semi-permeable.

However, when the vinyl siding is replaced with a traditional three-coat hard-coat stucco the combined wet cup permeance of both stucco, building paper and OSB (or plywood) sheathing is below 1.0 perm and therefore, this assembly is classed as vapor semi-impermeable. The application of the stucco in this manner clearly affects the drying characteristics of the wall; the stucco is relatively "airtight" whereas the vinyl siding is "air leaky."

If, instead of being installed directly over building paper or housewrap, the traditional three-coat hard-coat stucco is "back vented" (i.e. installed over an airspace), the assembly is once again classed as vapor semi-permeable.

Wet cup permeances are used because it is the performance of the assembly under "wet conditions" that we are concerned with.

Reference

This information was first published in Building Science Corporation's Builder's Guide to Cold Climates.