This overview summarizes spray foam wall construction including the advantages and disadvantages of this construction strategy. Complex two dimensional heat flow analysis and one dimensional hygrothermal modeling were used to determine moisture related durability risks for analysis.

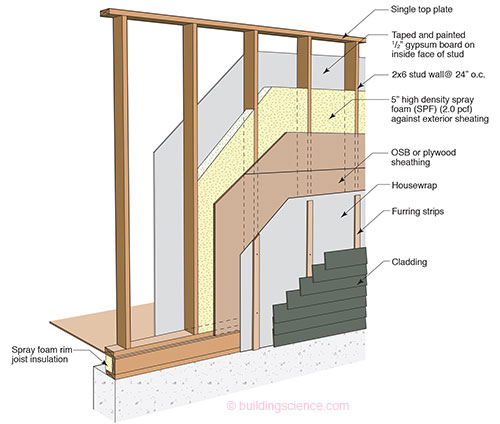

- Cladding

- Furring strips creating a minimum 3/8" ventilation gap/ drainage behing cladding

- Housewrap

- OSB or plywood sheathing

- 2x6 wood frame wall at 24" o.c. with 5" high-density spray foam cavity insulation

- Interior gypsum wall board

Thermal Control

Installed insulation R-value: The installed insulation R-value depends somewhat on the system manufacturer but generally speaking, high density foam (2.0 pcf) ranges between R-5.5 and R-6.5 per inch for the aged R-value, and low density foam (0.5pcf) has an R-value of approximately R-3.6/inch. Since high density foam is generally installed short of the cavity to avoid trimming, the installed insulation R-value is approximately R-30 (using R-6/inch). Low density is generally installed deliberately overflowing the cavity and trimmed off resulting in an R-value of approximately R-21.

Whole-wall R-value: Using two dimensional heat flow analysis with thermal bridging effects and average framing factors, it is clear that the thermal bridging through the framing, bottom plate, and top plate reduces the effectiveness of the spray foam insulation. The R-value of the high density spray foam wall decreases from an installed R-value of R-30 to approximately R-20, a decrease of R-10 because of thermal bridging. The low density spray foam wall decreases from an installed insulation R-value of 21 to a whole wall R-value of approximately R-16.

Air Leakage Control: Both low density and high density foam form an air barrier decreasing thermal losses through air leakage. Air leakage is still common under the bottom plate and at the rim joist if these areas are not detailed correctly.1

Typical Insulation: Low density 0.5 pcf foam, or high density 2.0 pcf foam.

Durability

Rain Control: Rain control is typically addressed using a shingle lapped and/or taped water control layer such as building paper or a synthetic WRB (i.e. housewrap). Intersections, windows, doors and other penetrations must be detailed to prevent the penetration of rain water.2

Air Leakage Control: Air leakage is significantly minimized by installing spray foam insulation in the stud space since both low density and high density spray foam act as an air barrier. This increases the durability of the wall system considerably over standard construction.3

Vapor Control: High density (2.0 pcf) foam forms a vapor control layer reducing vapor movement through the enclosure, minimizing the potential for wintertime vapor condensation and summertime inward vapor drive. Low density foam allows vapor movement through the foam so other methods of vapor control, such as kraft paper or vapor barrier paint, may be required based on the geographic location.4

Drying: Spray foam walls dry relatively slowly if water enters the enclosure, since they do not experience convective looping and air movement similar to air permeable insulations. Spray foam does not provide any buffering capacity or redistribution. Foam is relatively moisture tolerant and will be able to dry given enough time. Ventilation behind vapor impermeable claddings and interior components (e.g. kitchen cabinets) can encourage drying.

Built-in Moisture: Care should always be taken to build with dry materials where possible, and allow drying of wet materials before close in. High density foam will inhibit the drying of wet building materials more than low density vapor permeable foam.

Durability Summary: The primary durability risks associated with these wall assemblies involve moisture damage related to rain water penetration. Both air leakage and vapor diffusion durability is significantly increased with spray foam but some vapor control may be necessary with low density spray foam in cold climates.

Buildability

Using spray foam as the stud space insulation is a very simple modification to the construction technique. Generally, the wall construction is the same as standard or advanced framing construction, and spray foam is sprayed into the cavity. Spray foam significantly reduces risks of poor air tightness detailing of the exterior sheathing or interior drywall.

Cost

Using spray foam will increase construction costs considerably but these increased costs may be outweighed by the benefits to energy efficiency, and occupancy comfort from reduced drafts.

Material Use

Wood framing required for spray foam insulation is the same as required for the standard construction, or advanced frame wall depending on the framing strategy used.

Summary

This is highly insulated wall system that will work in extreme climates as part of a high-R enclosure.

References

- Straube, J. (2009, 04 22). BSD-014 Air Flow Control in Buildings.

- Lstiburek, J. W. (2006). Water Management Guide.

- Lstiburek, J. (2008, 08 20). BSD-104: Understanding Air Barriers.

- Lstiburek, J. (2008, 10 17). BSD-106 Understanding Vapor Barriers.