This overview summarizes flash-and-fill hybrid wall construction including the advantages and disadvantages of this construction strategy. Complex two dimensional heat flow analysis and one dimensional hygrothermal modeling were used to determine moisture related durability risks for analysis.

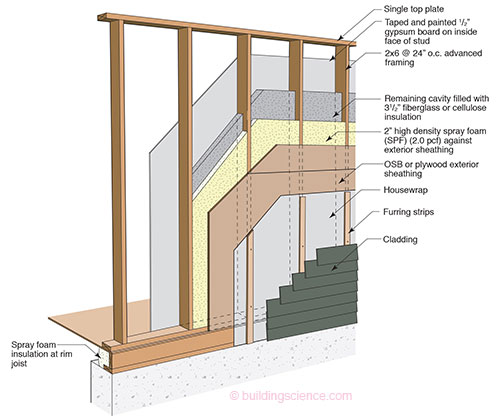

- Cladding

- Furring strips creating a minimum 3/8" ventilation gap/drainage gap behind cladding

- Housewrap

- OSB or plywood sheathing

- 2x6 wood frame wall at 24" o.c. with 2" high density spray foam and 3 1/2" fiberglass or cellulose cavity insulation

- Interior gypsum wall board

NOTE: Thickness of SPF will need to be increased in very cold climates to control temperature of condensing surface.

Thermal Control

Installed insulation R-value: The installed R-value is approximately R-12 for two inches of high density spray foam (2.0 pcf) and R-13 for three and a half inches of fiberglass batt, totaling R-25.

Whole-wall R-value: Using two-dimensional heat flow analysis with thermal bridging effects and average framing factors, the R-value decreases from an installed insulation R-value of R-25 to whole wall R-value of approximately R-17 for a the hybrid wall construction in this case. The decrease in R-value is due to the thermal bridging of the wall framing, top and bottom plates.

Air Leakage Control: Fiberglass batt, and both blown and sprayed cellulose are air permeable materials allowing possible air paths between the interior and exterior as well as convective looping in the insulation. Although dense pack cellulose has less air permeance, it does not control air leakage. In the case of the hybrid wall system, the spray foam is used as an air barrier in the stud space to limit the air movement between the interior and exterior so there are fewer energy losses due to air leakage. It is still possible and common to get air leakage below the bottom plate if it is not sealed.1 When spray foam is used in the wall system, it is beneficial to also use it in the rim joist which has a high potential for air leakage.

Typical Insulation Products: Spray foam insulation and fiberglass batt, blown fiberglass, blown cellulose, or sprayed cellulose.

Durability

Rain Control: Rain leakage into the enclosure is the leading cause of premature building enclosure failure. Rain control is typically addressed using a shingle lapped and/or taped water control layer such as building paper or a synthetic WRB (i.e. housewrap). Intersections, windows, doors and other penetrations must be drained and/or detailed to prevent the penetration of rainwater beyond the water control layer.2

Air Leakage Control: Air leakage condensation is the second largest cause of premature building enclosure failure with wood frame wall construction. It is very important to control air leakage to minimize air leakage condensation durability issues. An air barrier is required in this wall system to ensure that through-wall air leakage is eliminated (ideally) or at least minimized. An air barrier should be stiff and strong enough to resist wind forces, continuous, durable, and air impermeable.3

In the hybrid wall system, two inches of spray foam are used as an air barrier to reduce the air leakage. This also reduces the air leakage condensation against the sheathing in the winter as it significantly warms the condensation plane. Since air leakage from the interior into the studspace and back into the interior can also cause condensation in some climates, it is still important to detail the interior surface as an air barrier as well.

Vapor Control: Fiberglass and cellulose are vapor permeable materials, but including two inches of high density spray foam acts as a vapor barrier limiting vapor movement to the cold exterior sheathing, and significantly reduces the risk of vapor condensation durability issues. High density spray foam also decreases the summer inward vapor drives. If low density spray foam is used, it is not a vapor barrier, and other vapor control may be required depending on the climate.4

Drying: Cellulose and fiberglass insulation allow drying to occur relatively easily, so drying is controlled by other more vapor impermeable enclosure components such as the vapor barrier and OSB sheathing. Installing a vapor barrier on both sides will seal any moisture into the stud space, resulting in low drying potential, and possibly resulting in moisture-related durability risks. Ventilation behind vapor impermeable claddings and interior components (e.g. kitchen cabinets) can encourage drying.

Built-in Moisture: Care should always be taken to build with dry materials where possible, and allow drying of wet materials before close in. High density spray foam may slow drying across the enclosure since it is a vapor barrier. In geographic regions with reduced drying potential, the moisture content of the sheathing may stay elevated for an extended period due to the inability to dry or redistribute moisture into the wall. Ventilated claddings are recommended.

Durability Summary: Hybrid wall construction has a greater resistance to both air leakage condensation and vapor diffusion condensation because of the high density spray foam increasing the dew point of the condensation surface. The primary durability risks associated with these wall assemblies involve moisture damage related to rain water penetration.

Buildability

Hybrid wall construction is not very different from standard wall construction or advanced framing. By filling the stud space with two inches of spray foam, an R-13 batt can still easily be installed against the foam, or cellulose could be sprayed in the remaining stud space. All other aspects of the construction are the same as standard construction or advanced framing. Using high density spray foam reduces the risks from poor workmanship during construction.

Cost

Using spray foam insulation can be costly, and while it reduces the risks of moisture related durability issues, the minimal increase in R-value due to the thermal bridging may not be worth the increased cost of the spray foam insulation.

Material Use

There is no increase in framing materials from standard construction, but the embodied energy of the system increases with the addition of high density spray foam insulation.

Summary

This is highly insulated wall system that will work in extreme climates as part of a high-R enclosure.

References

- Straube, J. (2009, 04 22). BSD-014 Air Flow Control in Buildings.

- Lstiburek, J. W. (2006). Water Management Guide.

- Lstiburek, J. (2008, 08 20). BSD-104: Understanding Air Barriers.

- Lstiburek, J. (2008, 10 17). BSD-106 Understanding Vapor Barriers.