This overview summarizes double stud wall construction including the advantages and disadvantages of this construction strategy. Complex two dimensional heat flow analysis and one dimensional hygrothermal modeling were used to determine moisture related durability risks for analysis.

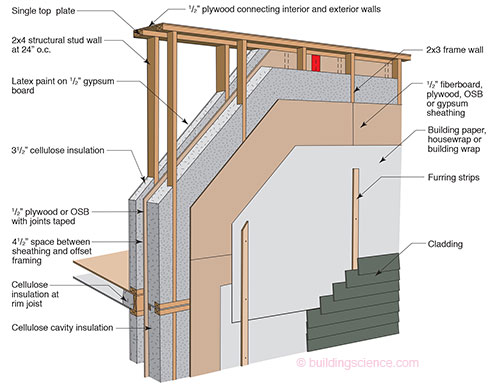

- Cladding

- Furring strips creating a minimum 3/8" ventilation gao/drainage gap behind cladding

- Housewrap

- Fiberboard, plywood, OSB or gypsum exterior sheathing

- 2x3 exterior wood frame wall at 24" o.c. with cellulose cavity insulation

- 4 1/2" space between sheathing and offset framing with cellulose insulation in gap

- Plywood or OSB with joints taped

- 2x4 structural interior wood frame wall at 24" o.c. with cellulose cavity insulation

- Interior gypsum wall board

Thermal Control

Installed Insulation R-value: The thickness of double stud walls varies; however, walls with overall insulation thickness of 91/2” appear to be most common. The insulation can be either fiberglass batt (R-3.5/inch) or blown cellulose insulation (R-3.7/inch) resulting in overall installed insulation R-values of R-33 and 35 respectively.

Whole-wall R-value: Using two-dimensional heat flow analysis with thermal bridging effects and average framing factors demonstrates that adding an exterior framed wall with an insulation filled gap greatly reduces the thermal breaks through the stud wall and can increases the clear wall R-value to R-34 depending on the thickness of insulation. However, because of the significant thermal losses at the rim joist, the whole-wall R-value is closer to R-30.

Air Leakage Control: Fiberglass batt, and both blown and sprayed cellulose are air permeable materials allowing possible air paths between the interior and exterior as well as convective looping in the insulation. Although dense pack cellulose has less air permeance, it does not control air leakage. Accordingly, the primary air control layer is the plywood or OSB sheathing on the exterior of the interior frame wall.

Typical Insulation: Fiberglass batt, or blown cellulose; blown fiberglass is another option, but not too common.

Durability

Rain Control: Rain leakage into the enclosure is the leading cause of premature building enclosure failure. Rain control is typically addressed using a shingle lapped and/or taped water control layer such as building paper or a synthetic WRB (i.e. housewrap). Intersections, windows, doors and other penetrations must be drained and/or detailed to prevent the penetration of rain water beyond the water control layer.1

Air Leakage Control: Air leakage condensation is the second largest cause of premature building enclosure failure with this type of wall construction. It is very important to control air leakage to minimize air leakage condensation durability issues. An air barrier is required in this wall system to ensure that through-wall air leakage is eliminated (ideally) or at least minimized. An air barrier should be stiff and strong enough to resist wind forces, continuous, durable, and air impermeable.2

Air need not leak straight through an assembly to cause moisture problems; it can also leak from the inside, through the wall, and back to the inside; or it can leak from the outside, through the wall, and back to the outside. Condensation within the stud space is possible if this type of airflow occurs, depending on the weather conditions. Hence, wall designs should control airflow into the stud space.3

Vapor Control: Fiberglass and cellulose are highly vapor permeable materials, so a separate vapor control strategy must be employed to ensure that vapor diffusion does not result in condensation on, or damaging moisture accumulation in, moisture sensitive materials. The permeance and location of vapor control is dependent on the climate zone. Installing the vapor control layer in the incorrect location can lead to building enclosure failure.4 In this assembly, the vapor control layer is the plywood or OSB sheathing on the exterior of the interior frame wall.

Drying: Cellulose and fiberglass insulation allow drying to occur relatively easily, so drying is controlled by other more vapor impermeable enclosure components such as the plywood or OSB sheathing on the exterior of the interior frame wall. Installing a vapor barrier on both sides will seal any moisture into the stud space, resulting in low drying potential, and possibly resulting in moisture-related durability risks. Ventilation behind vapor impermeable claddings and interior components (e.g. kitchen cabinets) can encourage drying.

Built-in Moisture: Care should always be taken to build with dry materials where possible, and allow drying of wet materials before close in. Cellulose is often sprayed in damp, and manufacturers recommend drying before close in and moisture content limits. If a polyethylene vapor barrier is installed with relatively vapor impermeable OSB sheathing, drying could be slow if built-in moisture is present.

Durability Summary: The primary durability risks associated with these wall assemblies involve moisture damage related to rain water penetration or condensation (most likely the result of air leakage, but also potentially the result of vapor diffusion).

Cellulose insulated walls are slightly more durable because cellulose insulation is capable of storing and redistributing small amounts of moisture. Cellulose insulation is typically treated with borates to protect itself and neighboring wood material from mold growth and decay. Cellulose insulation also has decreased flame spread potential relative to other insulation materials.

Buildability

This wall construction is not very complicated, but does require custom frames around penetrations such as windows and doors.

Cost

The cost of this wall is higher than standard construction, but with a significant increase in thermal performance. This wall construction requires more time and materials for construction.

Material Use

The wall framing material is increased significantly by building a secondary exterior wall. This wall is not structural, which means the stud spacing can be wider, and smaller framing lumber can be used. There is also an increase in insulation, but the embodied energy of cellulose is relatively small, and results in large increases in R-value.

Summary

This is highly insulated wall system that will work in extreme climates as part of a high-R enclosure.

References

- Lstiburek, J. W. (2006). Water Management Guide.

- Lstiburek, J. (2008, 08 20). BSD-104: Understanding Air Barriers.

- Straube, J. (2009, 04 22). BSD-014 Air Flow Control in Buildings.

- Lstiburek, J. (2008, 10 17). BSD-106 Understanding Vapor Barriers.