Exposure to sunlight (ultraviolet radiation) and moisture are the major factors affecting the durability of paint coatings and the durability of the substrate. Ultraviolet radiation, moisture and heat can each lead to the breakdown of the resin in painted surfaces which binds (holds) the pigment to the substrate surface.

Paint has to:

• keep rain out of substrates

• breathe when it's on the outside or on the inside

• protect substrates from getting a sunburn

• look nice

Concerns

Exposure to sunlight (ultraviolet radiation), moisture and heat are the major factors affecting the durability of paint coatings and the durability of substrates (wood, plastics, etc.). Recall that UV, water and heat are "damage functions." Although, each factor can independently lead to deterioration, the effect of the combination of the three factors is much more severe than each factor separately. Ultraviolet radiation, moisture and heat can each lead to the breakdown of the resin in painted surfaces which binds (holds) the pigment to the substrate surface. When the resin breaks down, pigment is lost (washed away from the surface) and fading occurs. In some instances, rubbing the surface with a cloth or a hand will remove a white powder from the paint surface (chalking).

Paints vs. Stains

A paint coating's resistance to ultraviolet radiation and moisture is dependent on the ratio of resin to pigment in the paint. The more resin available to completely coat a pigment particle, the more forcefully the particle is bound to a surface. Premium paints have a high ratio of resin to pigment. A low cost paint typically has a high pigment content relative to resin content as pigment is less expensive than resin. Although a high pigment content paint has an excellent "hiding" ability, high pigment content paints with low resin contents are unable to resist expopermesure to sunlight and moisture. Gloss paints have more resin than semigloss paints, and semi-gloss paints have more resin than flat paints. Gloss paints have the most resistance to ultraviolet radiation and moisture; flat paints have the least.

Stains are not as hydrophobic or resistant to ultraviolet light as paints but are more vapor permeable. Since stains break down more rapidly due to ultraviolet light than do paints, re-coating more frequently with stains will be likely. Solid body stains are thin paints and should not be used. Do not use solid body stains.

Primers

The function of a primer is to prepare the substrate for the paint layer. A primer blocks the migration of extractives (tannins, wood sugars) from wood and the migration of salts from stuccos. Primers also help the adhesion of paints to surfaces such as concrete, metal, wood and plaster. They also provide a layer of "uniform" porosity that prevents the "over-absorption" of paint on non-uniform surfaces.

Oil-based primers are typically used on wood substrates as tannins and wood sugars, which are water soluble, are not soluble in oil.

Latex or water-based primers are typically reserved for plaster and drywall surfaces — or concrete and stucco.

Wood Substrates

Ultraviolet radiation, moisture and heat have a similar effect on wood as they do on the paint coating itself. Wood breaks down under exposure to ultraviolet radiation and heat and wood surface erosion is increased with exposure to ultraviolet radiation coupled with heat and rain.

The ideal coating system for wood is a system that is hydrophobic (sheds water), vapor permeable (breathes), resistant to ultraviolet light (sunlight) and has good adhesion (sticks to wood) and cohesion (stretching) properties.

Acrylic latex top coats coupled with premium latex primers are recommended when they are applied over stable substrates (dry, dimensionally stable and able to hold paint) as they are more vapor permeable than other paint finishes while providing similar hydrophobic, ultraviolet resistance, adhesion and cohesion properties. Two coats of allacrylic latex paint over a premium latex primer are recommended.

The optimum thickness for the total dry paint coat (primer and two topcoats) is 3.5 to 5 mils.

Oil-based prime coats coupled with latex top coats do not provide as permeable a system as a latex prime coat-based system. However, oil-based prime coats provide superior adhesion and stain blocking characteristics for difficult substrates. For woods with water-soluble extractives, such as redwood and cedar, oil-based prime coats are recommended. Do not use latex-based prime coats with these type of substrates.

Exposure of unprotected wood to sunlight can adversely affect the adhesion of paint to wood within as little as 3 to 4 week exposures. Wood surfaces should be painted as soon as possible, weather permitting. All exterior wood (except decking materials1) should be back primed or prime coated on all six surfaces. Ideally, wood should be pre-primed on all surfaces prior to arrival at the job site. Field cut edges should be sealed with primer during installation. Top coats should be applied within 2 weeks of field exposure of the prime coat. The sooner, the better. Some prime coats weather by forming a soap-like film that can interfere with adhesion of top coats. Washing aged prime coats (exposed to sunlight) is recommended prior to top coat application. Re-priming may be necessary if prime coats have excessively weathered. Ideally, the temperature should not drop below 50°F for at least 24 hours after paint application. Winter, late fall or early spring topcoat application is not recommended.

Pre-primed material should be utilized during winter construction and not topcoated (finished) until weather permits.

Stucco Substrates

Ideally, in cold climates, stucco claddings/renderings should not be topcoated with paints. Color pigments should be integrated into the topcoat/finish layer of the stucco itself. Unfortunately, this practice is no longer common, and stucco now is typically painted.

When painting stucco, water repellant vapor permeable coating paint systems are recommended. Recall that water vapor flow occurs from both a higher concentration to a lower concentration and from the warm side of an assembly to the cold side of an assembly. A rain wetted stucco cladding that is heated by solar radiation will be warmer and wetter than both the interior and the exterior air. Drying will be to the outside and to the inside. A heavy coat of impermeable paint over exterior stucco will blister under such conditions. The more vapor permeable the exterior paint coating, the better under such circumstances. Acrylic latex paints formulated for exterior use are recommended for almost all stucco applications.

Acrylic latex paints generally outperform "elastomeric" paints over stucco renderings due to the lower permeability of the elastomeric paints. Elastomeric paints have excellent crack spanning characteristics, but give up a degree of permeability to achieve the crack spanning ability. If water enters the stucco rendering at a joint or reveal or flashing or flaw, elastomeric paints have been known to blister. Elastomeric paints should be reserved for special conditions where substrates are severely cracked and crack spanning coatings are necessary and no other coating approaches are practical.

It is important that the stucco has cured sufficiently to reduce its pH2 prior to painting neutral pH (not acidic, not basic, just right — the "Goldilocks" pH is 7) is ideal for paint application. To determine the pH of stucco prior to painting, use "litmus paper" or just wait — 28 days is often recommended.

If waiting is not practical, apply a masonry primer containing alkali prior to painting.

Deck Substrates

Deck materials should never be painted as even vapor permeable paint coatings serve to inhibit drying of absorbed moisture beyond acceptable levels for such a hostile moisture environment (horizontal, exposed to rain and sun). However, deck materials can be coated with penetrating water repellents or stains. Both of these serve to reduce water absorption without reducing drying ability. In fact, it is critical to "back prime" or "back coat" or "back stain" decking materials to prevent cupping.

Untreated deck materials will deteriorate from both water absorption and exposure to ultraviolet light. Even preservative treated deck materials deteriorate from exposure to ultraviolet light. Stains provide satisfactory protection against ultraviolet exposure (sunlight). Straight water repellents do not. Stains act as a type of “suntan lotion” for the wood. Like most typical suntan lotions, stains must be regularly reapplied. Superior performance may be achieved when stains are applied over preservative treated decking materials.

Peeling Paint on Siding and Trim

Many paint problems with wood siding and wood trim are not paint problems at all, but are due to a fundamental defect associated with the underlying housewrap.

The problem with some housewraps (not all housewraps) is a loss of water repellency. The primary function of a housewrap is rain penetration control. Water repellency is a key element of rain penetration control. Once the water repellency of a housewrap is compromised, water can be absorbed by sheathings such as plywood leading to decay, mold and loss of strength. Additionally, water that is absorbed by sheathings is by definition water that is not drained out of the wall assembly. This absorbed water leads to paint problems with wood claddings and trim materials and in some cases decay of wood claddings and trim. This absorbed water migrates by capillarity and diffusion into wood claddings and trim out of the plywood sheathing through the hydrophobic

degraded housewrap.

Contaminants referred to as surfactants ("surface-active contaminants") either raise the surface energy of the housewrap or building paper or lower the surface energy of the water allowing the "wetting" of the housewrap or building paper surface by water. Once wetting of the housewrap or building paper surface occurs, material pores in the housewrap or building paper become filled allowing transport of liquid phase water across the housewrap or building paper via capillarity or hydrostatic pressure (gravity).

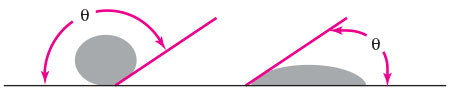

Figure 1 graphically illustrates some of the terms just used.

| • "non-wettable" surface | • "wettable surface |

| • water repellant surface | • non-water repellant surface |

| • hygrophobic surface | • hygroscopic surface |

| • water more attracted to itself than to surface | • water more attracted to surface than to itself |

| • surface energy of water greater than surface energy of surface | • surface energy of surface greater than surface energy of water |

| • water "beads up" | • water "spreads up" |

| • "greasy" surface | • "non-greasy" surface |

| • high contact angle "θ" | • low contact angle "θ" |

Figure 1: Surface Active Contaminant Properties

Water soluble extractives in wood such as tannins and wood sugars in redwood and cedar are a type of surfactant that contaminate the surface of housewraps and building papers raising their surface energy. Detergents and soaps are another type of surfactant that contaminate the surface of water lowing its surface energy. Both result in the liquid (in this instance "water") being able to "wet" the surface (in this case the building paper or housewrap). The surface energies of either the liquid or surface or both are altered so that the surface energy of the surface becomes greater than the surface energy of the liquid.

Back priming or back coating wood clapboards and trim helps to isolate the surfactants in the wood from the housewrap or building paper surface. Similarly, providing an airspace between wood trim and clapboards using furring or some other spacer ("cedar-breather") reduces the quantity and time liquid phase water is trapped in the exterior of the wall assembly thereby reducing the potential of surfactant movement. Where wood is concerned, both back-priming and an airspace are highly recommended.

Stucco and Housewrap

Where stucco is concerned, stucco should never be installed in direct contact with any of the plastic based housewraps. Stucco can "bond" or adhere to the housewrap surface altering its surface energy thereby allowing housewrap pores to become "wetted" and subsequently establish capillary flow. Another issue with stuccos is many stuccos have additives that improve workability and freeze-thaw resistance. These additives are typically surfactants.

A drainage space between stucco and building papers or housewraps is essential to control liquid phase water penetration. Bonding typically does not happen between stucco and building papers. However, with most stucco applications over building papers insufficient drainage results. It is recommended to use at least two layers of building paper under stucco in order to allow some drainage between the two layers. Even better is to provide a spacer between the two layers of building paper by using a textured building paper or a building paper with granules or cork adhered to its surface thereby creating a space.

Another analogy that might be useful in understanding some of the concepts involved is one of being inside of a tent during a rainstorm and pushing your finger against the inside of the tent surface creating a leak by both compressing and tensioning the fabric altering its surface energy.

Dirt and dust can also affect housewrap performance. Think of a fabric that is "Scotchgard™-ed" to be water repellent that subsequently becomes dirty. The fabric must be cleaned to remove the contaminants and retreated to reestablish water repellency. Don't let you housewraps become muddy or dirty.

Interior Surfaces

Paint coatings installed on interior surfaces can be either permeable or impermeable depending on the design of the wall assembly. On wall and basement assemblies which are designed to dry to the interior, only vapor permeable paint systems (latex paint) should be used.

On wall and roof assemblies which require a surface applied interior vapor retarder, a vapor impermeable paint system should be used. These coatings are available in both latex-based and oil-based systems.

Paints with low or no emissions of volatile organic compounds (VOC’s) should be selected for interior applications to reduce concentrations of interior contaminants.

Footnotes:

- Decking materials should be stained on all six surfaces, not painted.

- The negative logarithm of the concentration of hydrogen. Knowing this definition is important only when confronted by a Jeopardy-watching crazed stucco contractor who wants to know why some idiot screwed up his finish coat by painting it.