Putting ductwork outside is bad enough, but putting ductwork in an attic is even worse (Photograph 1). Attics are even hotter than outside during the summer and as cold as the outside in the winter. Of all of the places to put ductwork in I can’t think of a worse place. Everyone knows this.

Photograph 1: Ducts in Vented Attic – At least they are shiny. What are the odds that they are tight? Good luck with that.

So why does it happen? Why not just say don’t do it? Ah, if life was only this simple. Architects and builders are the guilty parties here2. They don’t leave space inside the house for furnaces, air conditioners and ductwork. Except up north where we have basements. I am pretty sure that the reason basements were invented was to provide a place to stash the furnace and run the main ductwork trunks.3 No basement—no space for stuff—up in the attic we go. Bad. Very bad. Or is it?

First, lets understand the problem a little bit. When you install ductwork and air handlers in vented unconditioned attics they are exposed to extreme temperature and humidity conditions. Attic air temperatures during the day in the summer months pretty much everywhere where people live get to the 120 to 130 degree F range. That is bad enough, but it gets worse. The underside of roof decks that are covered with asphalt shingles can get to the 170 to 180 degrees F range and transfer radiant energy to the surface of ducts raising them well above attic air temperatures. Ouch.

We can live with the radiant transfer from the roof sheathing if we insulate our ceilings above R-304. Now that the codes call for R-49 in cold climates and R-38 pretty much everywhere else this radiant transfer becomes too small to care much about so radiant barriers are hard to justify at these attic ceiling insulation levels. Note that holds true for the energy transfer across the ceiling only. Not true for the ductwork in the attic. Unfortunately we do not have R-38 wrapped ducts and R-38 insulated air handlers. A good case can be made for radiant barriers to improve ductwork performance rather than for improving ceiling heat transfer. Amazing, eh. A radiant barrier for the ductwork in the attic not for the attic itself? Who knew? Of course you could wrap the ductwork itself in a radiant barrier. Shiny foil covered ductwork can be a beautiful thing. Only a crazy person would wrap the ductwork in black plastic and insulate the ductwork to R-6 and stash the ductwork in an unconditioned vented attic.

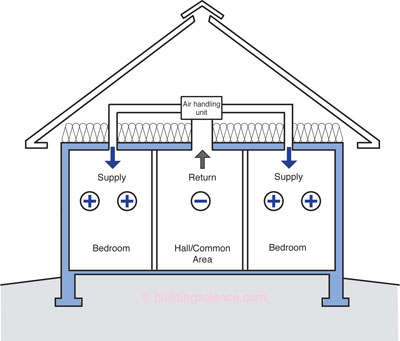

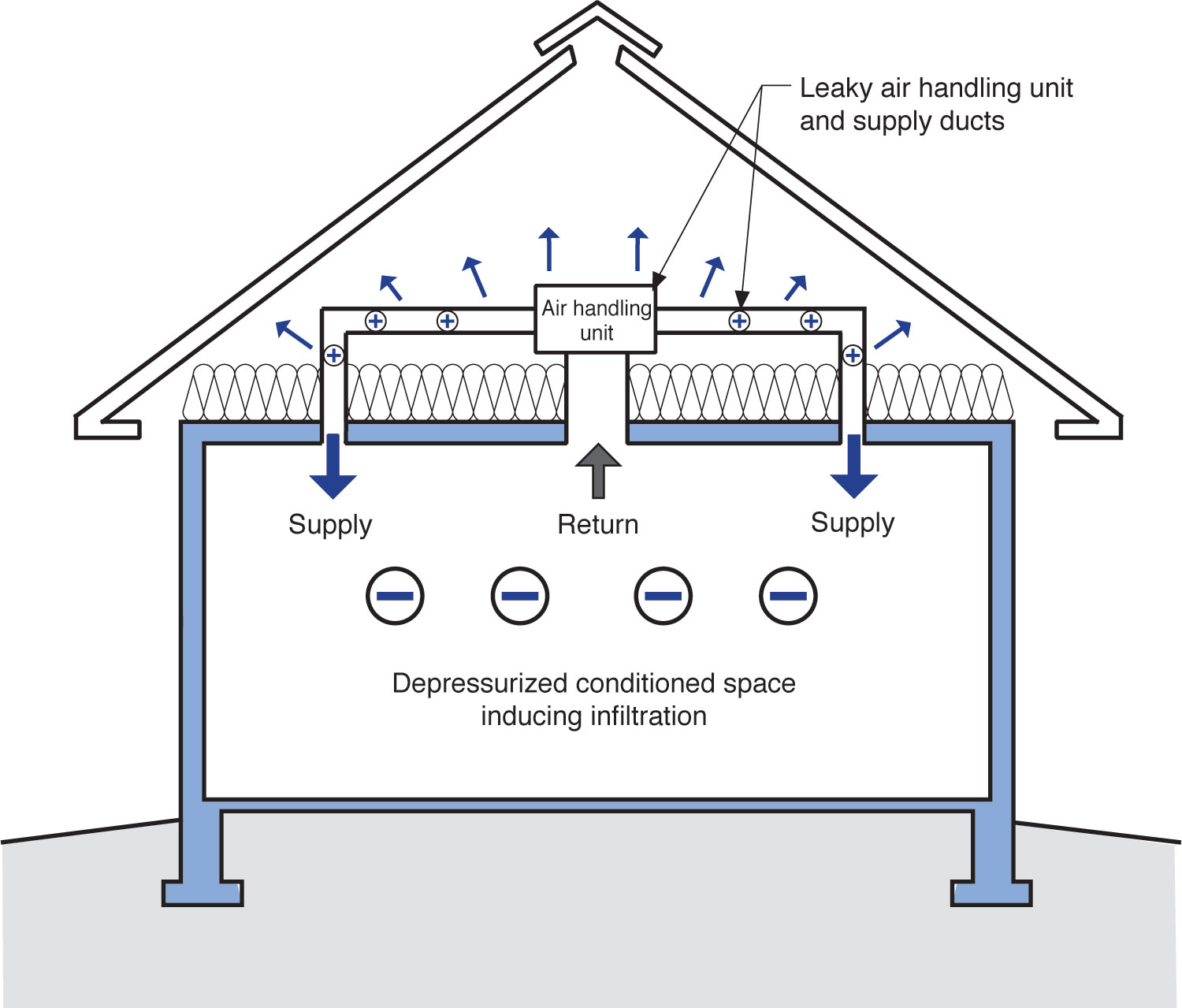

It gets worse. When you install leaky ductwork and air handlers in vented unconditioned attics you magnify the problems three to five fold. The house sucks—literally (Figure 1a). Add door closure and things spin out of control (Figure 1b). Typical ductwork installed in vented attics in the late 1980’s and early 1990’s leaked about 20 percent. Then a legend appeared and pointed out the problems. John Tooley changed the residential building industry with his whit, knowledge and determination to fix the problem.5 Negative pressures in southern houses. Who knew? John knew. And they were big pressures. Tripled air change rates. Leaky ducts by themselves were 30 to 35 percent of the total energy load of a Florida or Texas home.

Figure 1a: Really Negative – Ductwork and air handlers typically leak and when the are installed outside of the conditioned space such as in a vented and unconditioned attic significant negative pressure occur inside of the conditioned space that lead to significant energy penalties in all climates and large latent loads in humid climates

Figure 1b: Even More Negative – When you then install systems with central returns that are also unbalanced in that return paths are not provided from bedrooms to the central returns the pressure effects are magnified. Undercutting doors does not work unless you have a “knee high” undercut.

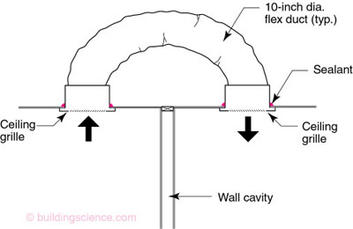

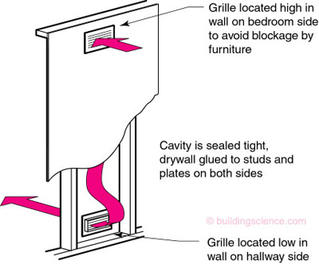

John Tooley said fix the ducts and you fix the pressures and the air change rate and you save energy and you deal with the latent load to boot. I said yeah, but it ain’t going to happen. There is no way the skill set of the industry could be changed that much. He said I did not respect the trades enough and that I was clearly wrong. He pushed mastic and duct testing6 and pressure balancing via jump ducts (Figure 2a) and transfer grilles (Figure 2b). I did not believe him. I said the only way to fix the problem is to put the ducts inside because no one is going make the ducts tight enough to make the problem go away. He said there is no room. I said I would make room. Just move the air control layer and the thermal control layer to the roof deck. Make the attic a conditioned space—make it a southern basement—a place to stash the air handler and ductwork. I went the unvented conditioned attic route—he went and changed the industry. It turns out both approaches worked. But not without issues.

Figure 2a: Jump Ducts – This addresses the problem in Figure 1b. What is nice about this approach is that it is quiet – no sound transfer. Also known as a “slinky”.

Figure 2b: Transfer Grilles – This also addresses the problem in Figure 1b. Less expensive than a “jump duct” but not as quiet.

Thanks to John Tooley’s perseverance plus help from a whole bunch of other folks (most notably Neil Moyer) who got with the program it became clear that you could get ductwork down to 3-to-5 percent leakage from 20 percent. I was proven wrong. Note that it was nice to loose this one. But the ductwork was still in the attic. The best combination with this approach was locating an air handler in a closet inside the house (we could get folks to do that) and airtight ducts (my definition which is John’s definition of 3-to-5 percent) located in the attic.

Still bad but not ugly bad. Add transfer grilles and make the ceiling penetrations airtight and we sorta got somewhere.

With my unvented roof conditioned attic approach we got the ductwork completely in the conditioned space but we increased the surface area of heat gain and heat loss. And we had to deal with condensation issues of interior moisture on the underside of roof decks. Well we figured out the condensation issues. But it was not cheap —rigid insulation over the top of the roof deck or spray polyurethane foam (SPF) on the underside of the roof deck. This made no energy sense—except when it did. The conditioned attic approach resulted in huge reductions in building enclosure air leakage. Without this energy conservation “bump” we get on overall building airtightness the approach would not make energy sense. Even so, with the airtightness improvement it still did not come close to the best of the best approach that was locating the ductwork and air handler inside the conditioned space and locating a vented attic over the top of the house. Duh.

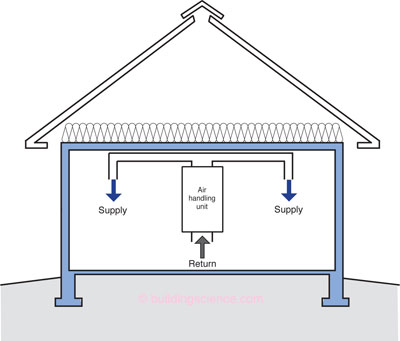

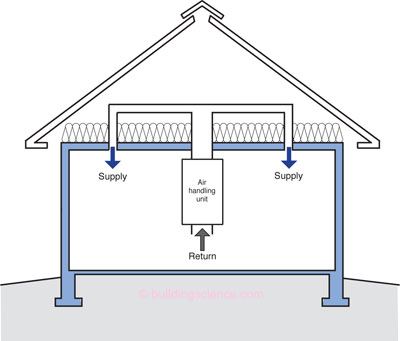

The numbers tell the story. I know lots of you know this, but how about one more time for old times sake? Take the best case: a house with an airtight ceiling with a vented attic and code levels of attic insulation and all the ductwork and air handler inside the conditioned space and compare it to the other options (Figure 3a). The moment you put the ductwork in the attic (while keeping the air handler inside) having this ductwork airtight (installed by John Tooley himself) with an airtight ceiling (installation watched over by me) all penetration and boots and stuff sealed you have about a 10 percent energy hit on cooling and heating compared to the base case (Figure 3c).

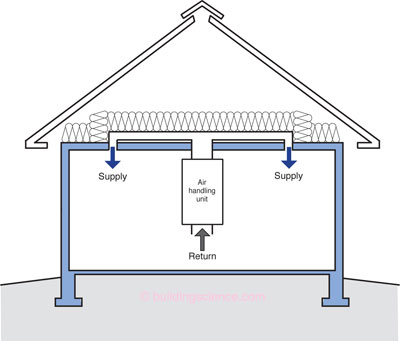

Figure 3a: Base Case – The best of the best. Ductwork and air handler inside the conditioned space with a vented attic on top with an airtight ceiling and code levels of attic insulation. It does not get better than this anywhere anytime.

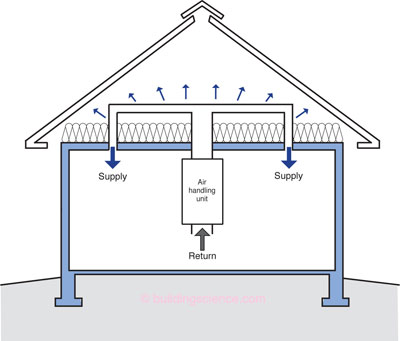

Figure 3b: Ugly and Unfortunately Typical – This is a 30 percent or more energy hit on cooling and heating compared to the base case.

Figure 3c: Less Ugly – The moment you put the ductwork in the attic (while keeping the air handler inside) having this ductwork airtight (installed by John Tooley himself) with an airtight ceiling (installation watched over by me) all penetration and boots and stuff sealed you still have about a 10 percent energy hit on cooling and heating compared to the base case. This is much better than Figure 3b but it sure ain’t Figure 3a.

Now let’s say that you don’t have John Tooley around to do the ductwork and you don’t have me around to make sure the ceiling is sealed perfectly you get a 30 percent (or more) energy hit on the cooling and heating compared to the base case (Figure 3b). This is really, really bad. Yes, I knew you knew that. If we could fix only this thing we could change the world. Yes, an exaggeration, but folks seem to forget how ugly this really is, so exaggeration is warranted.

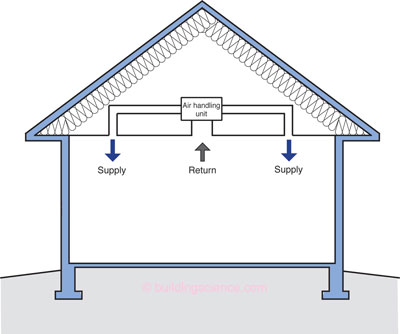

OK, now lets do a conditioned attic. You get the same airtightness compared to the base case and you get the ductwork in the conditioned space. Great. But you get a larger insulated surface area on the top of your house and that hurts you. The conditioned attic even done “right” is still a 10 percent energy hit on cooling and heating compared to the base case (Figure 3d). Nothing beats the base case. Interestingly enough both John Tooley and I ended up at the same spot except he spent a lot less money.7

Figure 3d: Ugly Beautiful – Conditioned attic. With my unvented roof conditioned attic approach we got the ductwork completely in the conditioned space but we increased the surface area of heat gain and heat loss. This is a 10 percent energy hit on cooling and heating compared to the base case because of the increased surface area. And here is a “heads up”: don’t buy the argument that you don’t need as much “R-value” when you “cathedralize” the attic. You should install “code levels” of insulation when you do conditioned attics – sloping or flat or cathedral or whatever.

Is there another option? Yes. Take the John Tooley option, make the ducts airtight, make the ceiling airtight and insulate the bejesus out of the ducts by covering them with lots of stuff (Figure 3e). You can cut that 10 percent hit to less than 5 percent—maybe to 38. Now you just can’t “bury” the ducts or they will sweat. You have to insulate them with an impermeable layer of spray polyurethane foam and then you can bury them (Photograph 2). You need to do this in all climates except in the desert. Of course while you are in the attic with that SPF why not take the opportunity to seal all those holes that are up there. Nothing works better than SPF for those nasty holes. And then while you are in the house with that SPF do the other holes. Like the ones between the garage and the house. Tight is right.

Figure 3e: Buried Ducts – Take the John Tooley option, make the ducts airtight, make the ceiling airtight and insulate the bejesus out of the ducts by covering them with lots of “fluffy stuff”. You can cut that 10 percent hit to less than 5 percent.

Photograph 2: Condensation Control – Yes, there is a duct under all that spray polyurethane foam (SPF). You just can’t “bury” the ducts or they will sweat. You have to insulate them with an impermeable layer of spray polyurethane foam and then you can bury them with “fluffy stuff”. Note the impermeable part – only closed cell, high-density (2 lb/ft3) SPF works. Of course while you are in the attic with that SPF why not take the opportunity to seal all those holes that are up there. Nothing works better than SPF for those nasty holes. And then while you are in the house with that SPF do the other holes. Like the ones between the garage and the house.

Note that even when you bury the ducts and foam them to control condensation it is still not as good a having all the ductwork and air handler inside the house. Also note that burying the ductwork and foaming them is not free. How much does it cost? Depends. But it seems to be in the same ballpark as moving the ductwork into the conditioned space—except without a lot of brain damage—read on.

Huh? You mean it is not free to move the ductwork into the conditioned space? Nope. If you are an industry that has been building hundreds of thousands of homes with ductwork in the attic for decades and one day you decide that they should all go inside, you are going to not have an easy go of it. Brain damage is the word I use here. There will be clever framing, there will be soffits and there will be dropped ceilings (Photograph 3 and Photograph 4) and there will be lots of redesign. Is it worth it? Yes, to me it is. Should you do it? Yes, I think you should. But not everyone sees it that way and so the good news is that we have two other viable options—bury the ducts or construct conditioned unvented attics.

How about ducts that are airtight in vented attics but not buried but with radiant barrier roof decking or radiant barrier ductwork coverings? Gets you a couple of percent—probably into the 7ish to 8ish energy hit range. OK, that helps too. So maybe we have a third option. Options are always good. But remember the best option is to keep the stuff inside. Obvious I know, but saying the obvious is why I get paid the big bucks.

Photograph 3: Bulkhead Framing – Moving the ductwork into conditioned space typically requires bulkheads and soffits that are airtight.

Photograph 4: Soffit for Ductwork and Services – Changes the appearance. Sometimes folks like it, sometimes not.

References

Cummings, J.B. and Tooley, J.J.; “Infiltration Rates and Pressure Differences Induced by Forced Air Systems in Florida Residences”, ASHRAE Transactions, June 1989.

Cummings, J.B.; Tooley, J.J.; and Moyer, N.A.; “Impacts of Duct Leakage on Infiltration Rates, Space Conditioning Energy Use, and Peak Electrical Demand, Proceedings of the ACEEE 1990 Summer Study on Energy Efficiency in Buildings, August 1990.

Lstiburek, J.W.; Unvented Attic Performance, ASHRAE/BETEC, Thermal Performance of Buildings VII, Clearwater Beach, Florida, December 1998.

Rudd, A.F. and Lstiburek, J.W.; Vented and Sealed Attics in Hot Climates, ASHRAE Transactions, June 1998.

Rudd, A.F., J.W. Lstiburek, and N.A. Moyer; “Measurement of Attic Temperatures and Cooling Energy Use In Vented and Sealed Attics in Las Vegas, Nevada”, EEBA Conference, Minneapolis, MN, March 1997.

Tooley, J.J. and Moyer, N.A.; Mechanical Air Distribution and Interacting Relationships, Florida Home Energy Reviews of Orlando, Orlando, Florida, 1988.

- Never waste a fad that you can take advantage of. I loved the story of the boys publicizing their cable show in NYC where Jase tried to check into the Plaza. He was in the process of being tossed out because they mistook him for a homeless person until someone recognized him. Uncle Si said it was a case of “facial profiling”…

- Homebuyers too. They don’t want to pay for the extra space to put stuff inside or they don’t want to give up existing space to put stuff inside or they don’t like the look of stuff when we put stuff inside. But if architects and builders had brass ones they would say no we won’t do it that way because it is bad and bad is bad…..Yeah, right, dream on.

- Until recently basements weren’t all that great to put furnaces and ductwork in. Historically they were not really basements at all, but cellars. Damp, dark, musty, ugly places were the bogeyman lived. Note, the term “bogey” came from “Bugis” who were rather nasty pirates operating near Java – the place, not the computer language. Adults used to scare little ones with “bogey stories”. Now we use stories of healthcare reform to do the same thing. Alas, cellars are no more and we have figured out how to construct basements so they are dry and comfortable and perfect for furnaces, air conditioners and associated ductwork.

- Hat tip to Philip Fairey and the FSEC folks who know more about radiant barriers than anyone else. They did the heavy lifting in the 1980’s. Poorly insulated vented attics benefit from radiant barriers. Well-insulated vented attics do not. Well-insulated means above R-30.

- I first met John in a parking lot at 6 am in Atlanta in 1986 where we had both spent the night in our vehicles because neither one of us could afford a room. He spent the night in a rusted Chevy Van and I spent the night in a rusted Ford Tempo with bald tires. I had driven down from Toronto because I couldn’t afford the airplane ticket. He drove up from Orlando for the same reason. Neither one of us knew we were in the same parking lot until the morning when we woke up and found ourselves sharing the same bush to do our business. We were both at Southface doing a Denis Creech thing. He taught me ducts. There is no better teacher, speaker educator in the world than John. People forget John’s impact. He didn’t write lots of papers – certainly not peer reviewed ones that get cited in the literature —but make no mistake he is the Duct Commander.

- This is where Gary Nelson comes in. John needed a way to test ducts. Gary came up with the Duct Blaster® and an affordable digital manometer. He already had an affordable blower door. One legend begets another legend. Truth be told Gary is a troublemaker. He is the one who told me to go to Atlanta to meet that lunatic legend Tooley.

- I said it this way to get a rise from a whole bunch of folks. This statement is true only with simple houses built like square boxes with flat ceilings without hundreds of penetrations for stupid homeowner stuff – like the stuff in my house – and certainly without architects on drugs being clever with massing making “a statement”. With complex custom homes with complex roof and ceiling geometries or where you are doing complex retrofits the unvented conditioned attic approach wins because it is the only option. You can’t get the ceiling airtight nowhere no-how in those situations.

- The folks at CARB have done some good work on this under the Building America Program – http://apps1.eere.energy.gov/buildings/publications/pdfs/building_americ... even better just go to the BA website and browse the “Solution Center”.