It’s pretty easy to deal with new basements. They are not hard to insulate. The majority of them do not leak or smell and the buildings on top of them are generally not rotting.1 If you want a challenge try dealing with century old houses sitting on top of rubble foundations. These houses are not going away and sooner or later we are going to have to fix them and insulate them.

The good news is that we know how to do it. The bad news is that there are not too many shortcuts. The days of plugging in a dehumidifier in the basement and hanging fiberglass batts from the rim framing are long gone. And you can forget about insulating the main floor (the basement ceiling) and pretending that the basement isn’t there. Whether you like it or not the basement is coupled to your house – especially when that is where your furnace and water heater and boiler and who knows what else are located.

In dealing with rubble foundations first we have to deal with the water. Then we have to deal with the water. And finally we have to deal with the water. Did I mention we have to deal with the water? Unless you are very, very lucky almost all rubble foundations leak and are damp.

Every civil engineer will tell you that the best way to deal with leaking foundations is to dig them up from the outside, install perimeter drainage on the outside, install a drainage layer over waterproofing on the outside and call it a day. That’s the theory and the theory works.2

However, contrary to popular thinking you don’t have to dig them up to fix them and to insulate them. We can get there for a lot less effort and money and that is good when you are lazy and cheap.

Check out the house in Photograph 1. Built in 1880 on top of a rubble foundation. It was a dump. Every time it rained the basement flooded. And it wasn’t really a basement. It was sort of a tall crawlspace with a short crawlspace attached to one side. The house smelled. It smelled bad. Moldy, musty, and dirt-like. The floors were freezing in the winter. During cold weather it was not possible to keep the basement door closed because of the draft rushing up from purgatory. In other words it was the perfect house for us so we bought it–yup, my bride and I live in this house.

Photograph 1: Looks Good Now—You should have seen this place when the timber frame was rotting and the basement was smelly and the rubble foundation was leaking and the floors were freezing.

We couldn’t afford to dig it up from the outside because we didn’t have the money and besides the "Historical Commission”3 wouldn’t let us. They didn’t want us to touch the appearance of the rubble foundation that extended above grade.

What to do? The lack of money is the mother of all innovation.4 The approach we took was to connect the short crawlspace to the tall crawlspace, provide interior drainage and to separate the wood structure from the rubble foundation with a capillary break. And then insulate on the inside with spray polyurethane foam. The approach worked so well we have done a gazillion more in the two decades since. And so have other folks.

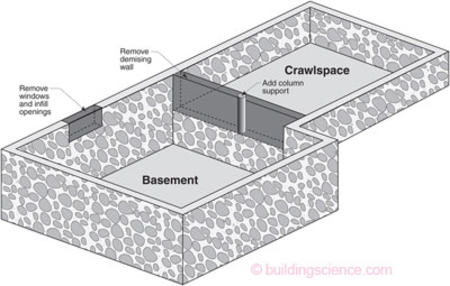

Figure 1 and Photograph 2 illustrate connecting the two crawlspaces (or mini basements) to one another creating a single zone. Crawlspaces need to be either completely “outside” or completely “inside.” Completely inside is easier when a basement is also involved. The rubble demising wall separating the crawlspace from the basement was knocked out and replaced with a column. Eliminating the rubble demising wall also eliminated two significant intersecting thermal bridges. Note that we also removed and filled in the small crawlspace-basement windows with concrete. These basement windows were nothing more than primitive holes that were, in essence, water leaks, thermal leaks and rot factories.

Figure 1: Make A Single Zone—Connect the short crawlspace to the basement by removing the short demising wall. Eliminating the rubble demising wall also eliminates two significant intersecting thermal bridges.

Photograph 2: Knocking Out the Demising Wall—Note the small short column that replaces the supporting demising that was removed to connect the crawlspace to the house basement.

The entire house was then lifted 1 inch in order to insert a sheet plastic butyl membrane capillary break (Photograph 3). And then the house was set back down. This is not as hard as it seems. In fact it is pretty straightforward. Small 10 ton hydraulic jacks were used with steel angle iron brackets that were lag bolted into the perimeter foundation wood member. We used 5 jacks rented from the local hardware store–three on the outside approximately 10 to 12 feet apart and two on the inside at the lifting mid points to keep the timber rim beam from rotating.5

Photograph 3: Disbelieving Neighbor—Yes, you can actually lift a house off its foundation a section at a time with small hydraulic jacks and steel angles lag bolted into the bottom of the timber frame. We used 5 jacks rented from the local hardware store–three on the outside approximately 10 to 12 feet apart and two on the inside at the lifting mid points to keep the timber rim beam from rotating. A membrane capillary break was installed between the top of the rubble wall and the timber frame.

Photograph 4: Foam Bathtub—Extruded polystyrene foam on top of a gravel layer on top of the existing combination dirt and broken concrete slab floor. The perimeter drain was located in the space between the foam “bathtub” and the perimeter foundation wall in the granular layer perimeter drainage zone. A new concrete slab was cast inside the foam “bathtub.”

And no, the plaster did not crack. Old buildings have a great deal of flexibility. We did a section at a time and worked our way around the perimeter. It took two guys three days to do the entire perimeter of the house. Along the way we replaced rotted sections of timber as necessary. And here’s a news flash to the structural engineers– there were no anchor bolts. Yup, old houses don’t have them. And the buildings are still here. They don’t blow away because they are very heavy. This gravity thing apparently is working for them.

Next came the interior perimeter drain (Photograph 4). We installed a foam “bathtub” on top of gravel layer on top of the existing combination dirt and broken concrete slab floor. This foam “bathtub” did not extend to the inside perimeter of the foundation. The perimeter drain was located in the space between the foam “bathtub” and the perimeter foundation wall. A new concrete slab was cast inside the foam “bathtub.” A sheet polyethylene butyl composite membrane lining was installed covering the interior perimeter rubble foundation wall and the upper short crawlspace floor (Photograph 5). This membrane lining was sealed to the capillary break that was installed on the top of the rubble foundation under the timber frame and also sealed to the new concrete slab cast inside the foam “bathtub.” The perimeter foundation drain and sub foam gravel layer was connected to an airtight sump crock. The sump crock contained a pump that expelled water to the exterior above grade (hidden behind bushes so as not to attract the attention of a bunch of loonie tunes you have already been briefed about).

Photograph 5: “Pool Liner”—A sheet polyethylene butyl composite membrane lining was installed covering the interior perimeter rubble foundation wall and the upper short crawlspace floor. This membrane lining was sealed to the capillary break that was installed on the top of the rubble foundation under the timber frame and also sealed to the new concrete slab cast inside the foam “bathtub.”

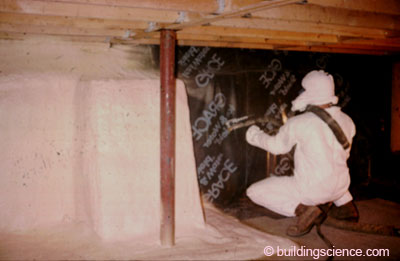

Photograph 6: Insulation Layer—The interior surface of the membrane lining was insulated with direct spray applied polyurethane foam – the high density closed cell stuff.

Photograph 7: All Done—The slab was painted to make it look pretty. Remember “green” means environmental.

Photograph 8: Intumescent Coating—A liquid applied ignition barrier is recommended as minimum protection for exposed spray foam. I think that perhaps a bigger brush would have made it go faster – just a thought.

The interior surface of the membrane lining was insulated with direct spray applied polyurethane foam – the high density closed cell stuff (Photograph 6). The slab was subsequently painted to make it look pretty (Photograph 7). A liquid applied ignition barrier–an intumescent coating is recommended (it is now a code requirement) and will eventually be applied (Photograph 8).6

The rubble foundation continues to leak ground water but this leakage is collected on the interior and then expelled back to the exterior.

The rubble basement renovation had a dramatic impact on the house. It stopped smelling. The floors were comfortable. The bottom of the house framing timber stopped rotting. We saved energy. Truth be told the smell thing and the comfort thing and the rot thing were more important than the energy thing. But the energy thing is nice. It is kinda’ free with the comfort thing and the odor thing and the durability thing. I mean this is one of the least expensive ways to fix a trashed rubble foundation and it is energy efficient to boot. The approach entered our repertoire of repair and interventions. And over the next two decades were learned a thing or two more and the approach evolved. Read on.

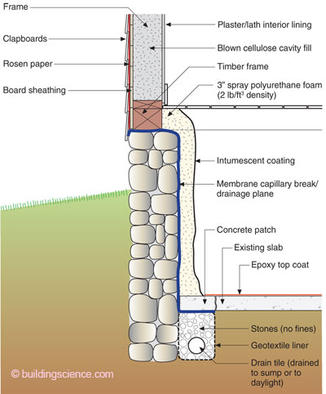

Most folks who don’t want to loose any headroom in basement foundations often install an interior perimeter drain in a trench (Photograph 9) rather than what we did at our house. This is also not as bad as it sounds. Most rubble foundations have very thin and weak ground slabs – if they are anything at all besides dirt – that are easy to break through with simple tools such as a pick, a pike and sweat. Occasionally, a concrete saw and an air hammer are required. This trench is lined with a geotextile filter fabric and contains a perforated drain and gravel with no fines. The drain tile is connected to a sump crock or to daylight. And then the interior membrane lining and spray insulation thing happens (Figure 2).

Photograph 9: Trenching For Perimeter Drain—Most rubble foundations have very thin and weak ground slabs – if they are anything at all besides dirt – that are easy to break through with simple tools such as a pick, a pike and sweat.

Figure 2: Interior Perimeter Drain—The trench is lined with a geotextile filter fabric and contains a perforated drain and gravel with no fines. The drain tile is connected to a sump crock or to daylight. And then the interior membrane lining and spray insulation thing happens. Epoxy coating over the top surface of the slab reduces vapor transmission into the space.

Many rubble foundations do not project much above grade. The installation of a robust capillary break is a necessity along with lowering the immediate adjacent grade (Photograph 10). Many of the bearing timbers typically have to be replaced due to serious rot (Photograph 11) and the sills have to be rebuilt (Photograph 12). These are not options, especially when insulation is added from the interior. Energy and airflow is no longer going to be available to assist in drying. Wetting from underneath needs to be eliminated and wetting from the outside needs to be controlled–exterior drainage planes and back ventilated claddings–or at minimum a back-ventilated “water table” trim detail. Tell the Historical Commission that Grandma heard her Grandma say that the house used to have one.

Photograph 10: Capillary Break Critical—Many rubble foundations do not project much above grade. The installation of a robust capillary break is a necessity along with lowering the immediate adjacent grade.

Photograph 11: Rotted Bearing Timbers—Many of the bearing timbers typically have to be replaced due to serious rot.

Photograph 12: Rebuilding Sill Assembly—Bolts and hangers and more bolts and hangers and still more…

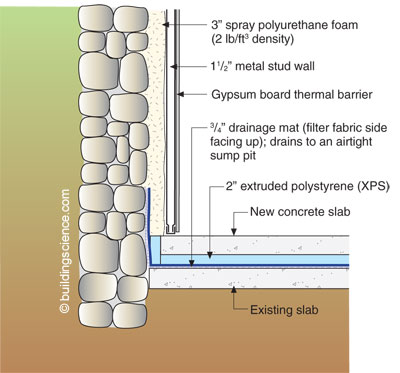

Where headroom allows insulating the top of the existing slab works well. Note the “foam bathtub” in Photograph 13 and Figure 3–but also note the “twist” in the approach. The cleverness of this detail is that a granular drainage layer under the foam insulation and “yet-to-be-cast” slab has been replaced with a ¾-inch drainage mat that extends up the walls about a foot. The ¾ inch mat does what 4 inches of stones used to do. Also note that the inside of the foundation wall is not completely lined with a membrane lining. There is only a membrane lining at the top of the wall acting as a capillary break. We are finding that the 2 lb/ft3 spray polyurethane foam works well as an interior drainage plane as long as drainage is provided at the bottom of the assembly. That’s where the drainage mat comes into play. The fabric on the drainage mat has to “face up” so that when it runs up the wall the fabric prevents the drainage matrix from being clogged by the spray foam when it is applied (Photograph 14). It also helps that the spray foam does not adhere to the rubble very well–especially if you don’t clean the wall before you spray. The lack of adhesion helps drainage. The foam itself is “structural” in that it is rigid enough to support itself if it is between 2 and 3 inches thick and if it adheres to the wood frame at the top of the foundation (which it does) and if it adheres to the edge of the foam bathtub at the bottom of the foundation (which it does).

Photograph 13: Another Foam Bathtub—Note the “twist” in the approach. The cleverness of this detail is that a granular drainage layer under the foam insulation and “yet-to-be-cast” slab has been replaced with a ¾-inch drainage mat that extends up the walls about a foot. The ¾-inch mat does what 4 inches of stones used to do.

Figure 3: Insulating Basement Slabs—Where headroom allows insulating the top of the existing slab works well. Note the “foam bathtub.”

Photograph 14: Spray Foam Layer—The foam itself is “structural” in that it is rigid enough to support itself if it is between 2 and 3 inches thick and if it adheres to the wood frame at the top of the foundation (which it does) and if it adheres to the edge of the foam bathtub at the bottom of the foundation (which it does).

The foam lining makes for a very nice home for some very happy mechanical equipment (Photograph 15). This equipment is best when it is sealed combustion and power vented as the old air leaky foundation is now pretty much airtight. As nice as the foam is to look at–notice the green color chosen for the concrete floor coating and the green tint to the foam itself–obviously very environmental–it really should be protected from mechanical damage and from ignition sources. That’s where thin lightweight steel framing and gypsum board are ideal (Photograph 16 and Photograph 17).

Rubble is no longer rubbish. A lemon is turned into lemonade. And oh yes, energy is saved.

Photograph 15: Mechanical Equipment—Very nice home for some very happy mechanical equipment. This equipment is best when it is sealed combustion and power vented as the old air leaky foundation is now pretty much airtight.

Photograph 16: Protection for Insulation Layer—As nice as the foam is to look at it really should be protected from mechanical damage and from ignition sources. That’s where thin lightweight steel framing and gypsum board are ideal.

Photograph 17: Gypsum Board Protection Layer—Gypsum is made from a type of rock–and rocks don’t burn–this is a good thing.

Footnotes:

Yes, yes, yes I know that “all yawl” (Texan plural form of “you all”) know of lots and lots of new houses that are rotting and have leaking basements. But they are the exception not the rule. And they are pretty easy to fix.

In theory communism works. You folks have no idea how hard I had to restrain myself from expanding on this footnote.

Also known as the “Hysterical Commission.” They are supported with tax money and pretty much make things up as they go along affecting property values capriciously and brazenly. These commissions are typically quasi-judicial tribunals that have authority without accountability. To beat them you have to take them to court where there are adults. Which takes time and money. I love old things especially old buildings. I want to be able to fix them so that they will be able to survive another century or two. To have to argue with someone who has an art-history degree and who could not get a real job is very irritating. Thank god for bourbon.

Apologies to Plato who first said “necessity, who is the mother of invention.”

Ask me how I know? Oh boy, did I ever get yelled at by the project architect—my wife. Memo to folks who do this, be sure to get an air gun to install and remove the lag bolts used to attach the angle iron lifting brackets. Goes very fast, very slick. Additional memo to folks who do this: if you run across anchor bolts just cut through them. You can add a bracket connection on the inside later if the gravity thing worries you.

The house is just off the Westford Town Common a short walk from where the firehouse is located. I asked the Fire Chief what I should do with the surface of the foam? He walked down to the house with a blowtorch and a knife. He hacked out a hunk of foam from the foundation wall and took it outside to the driveway. He ignited the foam with the blowtorch. When he pulled the torch away, the foam charred and the flame went out. He did this a couple of times – each time the result was the same and then he told me to install a couple of smoke detectors and buy a ticket to the fireman’s ball and walked back to the firehouse. God, I love old guys. Eventually applied in this case means if we ever have to sell the house.