All space-conditioning systems are intended to provide a comfortable and healthy indoor environment. Many, even most, systems are designed in such a manner that they cannot reliably provide fresh air and comfort while at the same time being energy efficient. In fact, the most popular residential furnace/AC systems and commercial VAV systems are fundamentally flawed from their conception.

How hard any space conditioning system needs to work depends on the design of the building, particularly the enclosure and the use of the building. However, some conditioning will be needed even for a super-insulated cube occupied by a dead hermit. The space conditioning may be provided by actively powered mechanical equipment or passive systems. However, the energy efficiency has more to do with not making the system work hard than not installing one.

It is useful to know what an ideal HVAC system would look like. Although compromises sometimes have to be made, they should be made with the knowledge of how and why they are imperfect. This article defines the characteristics of a perfect HVAC system for both single-zone single-family residential and multi-zone residential, commercial and institutional applications. Together with BSI-001 The Perfect Wall, it provides the basic concepts for energy efficient, durable, healthy, and comfortable buildings that can work in all climate zones.

Design Goals

A fundamental requirement for building design is to ensure health and safety. Hence, ventilation must always be provided when people are in the building, and some ventilation is needed to remove building-generated pollutants at all times. The required rate of outdoor air varies, from a few cfm per person to as much as 30 cfm (15 lps) per person depending mostly on politics. The challenge in practice is not the rate of ventilation, but actually ensuring that it is provided. In most cases, higher ventilation rates are used in an attempt to compensate for poor delivery reliability.

A comfortable indoor environment is about 20 to 24 °C (68 F – 75 °F) and 20-60% RH. If one widens the comfort range, a larger proportion of people will be uncomfortable. That does not mean that an indoor summer temperature of 26 °C (79 °F) will be uncomfortable for most people but it will be uncomfortable for a significant proportion (more than, say, 10%) of the North American population.

The temperature that defines comfort is not the air temperature, but something called the operative temperature. The operative temperature is a combination of the air temperature, the weighted average of all surface temperatures of a space (defined by the mean radiant temperature, MRT), and air velocity. At low air velocity, the operative temperature is the simple average of the MRT and air temperature.

With a high performance building enclosure (e.g. a perfect wall and exceptional glazing) the surface temperatures of a room will become very close to the air temperature, and comfort will be enhanced, even if the air temperature approaches the extremes of the comfort band. A typical modern building enclosure during cold weather will have wall and window surface temperatures that are several degrees below the indoor air temperature, and therefore to reach a comfortable operative temperature the indoor air temperature will need to be higher. The reverse is true in the summer.1

System Functions

Regardless of the quality of the building enclosure, some conditioning of the indoor space is required in essentially all climates. The list of required functions of any indoor environmental control system includes:

- Make it colder

- Make it hotter

- Increase humidity

- Decrease humidity

- Provide fresh air, and

- Filter air and remove pollutants.

Practically speaking one needs systems, active or passive, to:

- Make heat or remove heat (= make cold),2

- Move heat or cold around the building,

- Deliver heat or cold to the space,

- Add or remove moisture from the space,

- Move ventilation air around the building,

- Filter air to remove particulates and exhaust pollutants directly, and

- Reject heat to the environment (when cooling).

The best HVAC system is one that has discrete components that individually fulfill each of these functions. This allows each sub-system to be optimized for its function, and a control system can also easily be implemented to operate each function optimally with none of the compromises or trade-offs inherent in multi-role components.

The most dysfunctional, difficult to control systems combine multiple functions into one device. Although popular, these systems also often consume the most energy.

If reliability and comfort are the design goals, the choice of ground source heat pump, electric chiller, condensing boiler, or passive solar gain is secondary in importance to the choice of how the HVAC functions will be fulfilled. Choosing an energy-efficient source of heat (such as a condensing boiler) and cool (such as a modern chiller with IPLV of under 0.6) is often wasted by systems, such as VAV, that combine the functions of ventilation, humidity control, and heating/cooling. VAV systems, controlled by thermostats only, often reheat previously chilled air, and cannot reliably deliver the quantity of fresh air required (or over ventilate, often both). As a result, a less efficient heating/cooling plant in a system with separated functions can deliver significant energy savings at the same time as improving air quality, comfort, and reliability.

Small Residential HVAC Systems

A typical single-zone residential system uses a furnace and an air conditioning unit coupled with an air handling unit (AHU).3 This system separates the heat production, and cool production, and heat rejection functions with individual pieces of equipment. The heat and cool air generated in the AHU is transported via air in shared ductwork around the building (although hydronic and refrigerant systems are better, more expensive, alternatives they require the commercial approach described later). There is also a filter that removes airborne particles. A separate humidifier (although rarely needed in modern buildings) is sometimes included to add humidity. This sounds perfect, except for the fundamental flaw that there is almost never any provision to provide fresh air. This must be solved. There is also no ability to remove moisture (dehumidify) on demand. This also needs to be solved, especially in climates with humid weather.

To provide ventilation, a perfect system would provide separate ducted supply and return air systems. To reduce the energy used to heat or cool this ventilation air, a Heat Recovery Ventilator (HRV) can be used to transfer heat between the supply and exhaust streams as well as to provide the fans needed to move the air. In climates with significant outdoor heat and humidity, an Energy Recovery Ventilator (ERV) would be preferred to pre-cool and pre-dry incoming air using the cool and dry exhaust air.4 Of course point sources of pollutants, such as the kitchen stove and bathroom would have dedicated exhaust fans to remove these pollutants.

Heating or cooling would ideally be delivered to the space by radiant floors and ceilings respectively, as these provide the most comfort, with no moving parts in the space, with the lowest energy penalty and sound level. In very well insulated and airtight homes, the benefit of radiant conditioning is significantly reduced as the loads are so small and hence air-based delivery becomes a practical means of approaching “perfect HVAC” performance at a fraction of the cost of radiant systems.

In practice, it is feasible in small residential systems to use an air handler and space-conditioning duct system to distribute ventilation air throughout the house. This combination of uses (distribution of conditioning air with ventilation air) requires smarter-than-average controls to work (see later) and careful design to avoid excess energy use. But it can work very well for a single zone systems like small single-family homes and apartments.

The lack of humidity control provided by normal HVAC systems can be a major concern in climates with humid summer weather (e.g., Minneapolis, Miami). Only a random amount of dehumidification is provided if and when the cooling operates for long enough to allow water to collect, build up on coils, and then drain down and away. This process takes about 10-15 minutes of continuous cooling operation before dehumidification begins. Hence, a separate dehumidification device is required for the perfect HVAC system. Several suppliers of dehumidification ventilation equipment (often called an outdoor air unit in commercial applications) are now available to help solve this problem.

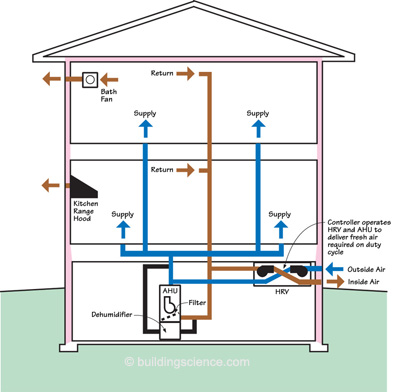

Combining these solutions provides the perfect practical manifestation of a residential HVAC system shown in Figure 1: energy-efficient, easy to control and trouble shoot, and guaranteeing a fresh air supply while controlling humidity. For the premium system, a radiantly heated floor and a radiantly cooled ceiling or valence could be added to this system relegating the air handling system to ventilation, mixing, filtration, and humidity control.

Figure 1: A small, single-zone residential heat, cooling, filtration and ventilation system that shares the ductwork between systems but separates the critical functions.

Larger Multi-Zone HVAC Systems

In commercial buildings (and large multi-zone residential), distributing the much larger quantities of energy around the building requires large ducts, and the associated larger inter-floor spaces to accommodate. Large ducts from central air handling units also penetrate multiple zones of occupancy and fire separation, causing all kinds of expense and performance problems. In the ultimate of madness, many multi-story MURBs actually use large ducts that penetrate through floor systems all the way to the roof, allowing flow to be regulated at the whim of stack effect pressures, and expect fresh air to find its way down corridors and under cracks below suite entrance doors! Hence the perfect commercial HVAC system uses liquids (such as refrigerant, water, or glycol) to move energy around the building, and only uses ducts to move ventilation air through the building while conditioning air temperature within each occupancy (residential unit, office tenancy, etc.).

By separating the control of temperature from the control of ventilation and from the control of dehumidification, very robust, simple to control, and energy efficient systems result.

For example, in a commercial occupancy, a central system can be used to produce chilled and heated liquid (water or refrigerant) by a range of technology. Space heating and cooling can then be delivered to the space by a range of products located in the space to be conditioned. For example, radiant heating and cooling systems embedded in the floors, walls, or ceilings. They, of course, require separate and good control of space humidity to be used in cooling mode. This type of “terminal unit” provide the quietest, most comfortable (by controlling MRT and air temperature), and lowest energy means of conditioning the temperature in a space.

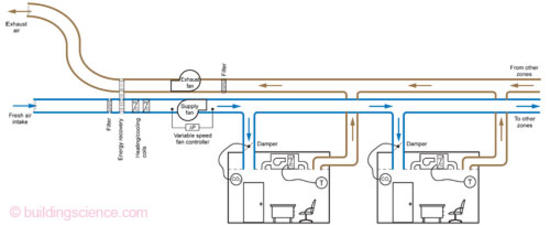

Figure 2: A multi-zone direct outdoor air system that dehumidifies supply air to offset occupancy and ventilation humidity, controls the ventilation rate dependent on occupancy, and heats or cool individual spaces with a radiant or fancoil terminal unit controlled by a space thermostat.

Other more economical approaches can be used that provide very close to the same performance. For example low-velocity fan coil units with dry coils and ECM motors that take air from the space and mix conditioned air back into the space are now available.5 Not only are these less expensive than radiant systems, they have a faster response time. Valence cooling and baseboard heating panels are other options.

A dedicated outdoor air system (DOAS) should be used in multi-zone or large single zone spaces to provide neutral temperature ventilation air independently of heating or cooling. Such a system will ideally incorporate some form of HRV or ERV. In multi-story buildings, a separate floor-by-floor DOAS is preferred to deal with duct penetrations through floors. Variable speed air handlers that maintain a constant pressure in the supply ducts should be the standard choice for this application. The use of a DOAS avoids the too common indoor air quality problem of re-circulating polluted air from one space or occupancy to another.6

Ideally, separate dehumidification equipment should be provided in each space. Practically speaking, most of the humidity load comes from the ventilation air and occupancy, and hence adjusting the supply air humidity level in a DOAS ventilation system can be used to control the humidity level within reasonable limits (e.g., +/-5% RH).

Controls

Of course, none of this equipment can work without the proper controls. Heating and cooling production should be controlled by a thermostat, located in the space to be conditioned. Only if a group of spaces will always have similar thermal loads, is it acceptable to share thermostats.

Despite what some may say, one cannot control humidity without the use of a humidity sensor coupled to humidity production / dehumidification equipment. These devices are called humidistats and are widely available and inexpensive. Typical cooling systems respond only to a signal from a thermostat and hence can only control temperature, not humidity, and therefore do not reliably control indoor humidity. There are no practical exceptions.

Ventilation should similarly be controlled by a “ventstat.” In most applications, ventilation has been provided based on a timer system, with assumed occupancy densities and times. This obviously has severe limitations in commercial/assembly occupancies and explains many air quality complaints: the occasionally-occupied meeting room is a common ventilation problem, and over-ventilated empty classrooms waste a huge amount of energy. The good news is that economical sensors that measure carbon dioxide (which is an excellent measure of both human occupancy and activity level) are now readily available. Hence, a CO2 sensor can act as a ventstat for a space, and control the supply of ventilation air as needed, when needed, as much as needed (of course a minimum ventilation rate is required even when no one is in the space to remove space-generated pollutants). This is generally termed “Demand Controlled Ventilation” (DCV).

A DOAS + DCV is absolutely the only “perfect” approach for large multi-zone commercial and institutional buildings, and practically the only energy efficient means of reliably delivering fresh air. Whether displacement ventilation, underfloor air, or high aspiration ceiling level air delivery and mixing is used has little impact on energy consumption, comfort or IAQ. DOAS+DCV has a tremendous positive impact. For single-zone housing, a simpler timer approach, combined with whole house mixing is more economical and usually more than sufficient7 although a small amount of energy can be saved by using a ventstat in zero energy home designs.

Complex integrated Building Automation Systems (BAS) are often touted as beneficial, even necessary, for energy efficiency and high performance. In fact, the opposite is often true. A system that requires a central controller to operate multiple pierces of equipment in concert to work is indicative of a problematic HVAC system design. Space conditions should be controlled by sensors in the space acting on equipment associated only with that space.

Supervisory systems, those that monitor but do not control, and central setpoint control, those that adjust zone target temperatures up and down after hours and on weekends, are quite useful, and fail in a tolerable fashion. But any system that needs to control remote pumps, chillers, and valves to meet humidity, temperature and air quality requirements in a space is almost always unnecessary and too complex to be properly built and commissioned, and rarely are such systems properly maintained and calibrated over the long term.

Conclusions

The perfect HVAC system concepts described here very reliably deliver, healthy, comfortable, and energy-efficient space conditioning. Many of the ideas in this article have been deployed in the past, but fallen out of favor as cheap energy, leaky buildings, and tolerant occupants allowed compromises and short-cuts. However, as the demand for better indoor air quality, comfort, and energy efficiency increase, the combination of decoupling the different required functions and the use of simple direct-coupled controls becomes imperative, not optional. Given good building enclosure design, such systems are not expensive to build, easier to commission and operate, and can save significant amounts of energy.

Footnotes:

Poor building enclosures, operative temperature, and zoning combine to explain the reasons behind the oft-heard complaint of why a building is cooled to a lower temperature in the summer than it is heated in the winter.

Recall that cold is a relative term meaning less heat. Hence, cooling means to remove heat.

Andy Ask honestly defines an Air Handling Unit (AHU) as “a box with a fan in it”. It is common to add a coil to add or remove heat, and a filter box to filter the air passing through an AHU.

It is important to note that an ERV can never, under any circumstances, dry the indoor air. It only reduces the humidity load due to ventilation, it can never eliminate it.

Parallel VAV boxes which draw return air from the space and condition temperature with dry coils are essentially less efficient versions of these fancoils.

It is likely unbelievable to many lay people, but most hospital conditioning systems will actually re-circulate air from one patient room to the public hallway or the adjoining patient room, thereby encouraging airborne pathogens to move around via the HVAC system. The problems this approach generates have traditionally been partially managed by very high air change rates, but such problems can be completely eliminated with low air change rates and DOAS systems.

The FanCycler™ controller was developed to inexpensively provide this type of control. It provides for user settings that varies the duty cycle of the indoor air handler operation.