Since there are large surface areas of interior gypsum wallboard in nearly all new houses, the effort centered around coatings that could be applied to those surfaces. This article was first published in ASHRAE Transactions, Volume 100, Part 1, pages 84-90.

Background and Purpose

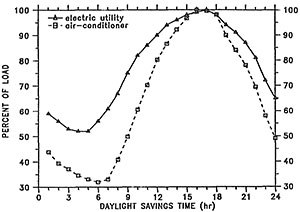

In many parts of the country, electric power utilities are finding that they cannot meet the summer peak electrical demands of their customers. Florida utilities in particular are faced with high growth rates; nearly every new house has central air conditioning. For the largest power utility in Florida, the average peak summer day demand profile has nearly the same shape as the demand profile of a house's air conditioner for the same time period. Figure 1 shows the utility load shape (Taylor 1990) and the measured average load profile of 58 residential central air conditioners (Paxon and Hinchcliffe 1980) in percent of load. If some of the peak air-conditioning demand could be shifted to off-peak hours, there would be a tremendous savings in capital costs of electricity-generating equipment. The utility's savings could eventually translate into lower costs for customers.

Figure 1: Average peak summer day load shape for a Florida electric utility and the average load shape of 58 residential central air conditioners

Thermal storage concepts for off-peak cooling in residential buildings have been heavily researched but have rarely been put to use. The economies of scale, demand charges, and time-of-day rates have made ice-storage systems popular for load shifting in commercial buildings, but ice storage generally has not been cost-effective for residences. The equally iznportant concept of moisture storage in buildings is only beginning to gain prominence in the research co~nmunity.

What is needed is a low-cost way to integrate both thermal and moisture energy storage into the building itself (Fairey and Vieira 1984). Work by Shapiro et al. (1987) and Salyer and Sicar (1989) identified phase-change material (PCM) wallboard as a method to achieve thermal storage in buildings. Side-by-side room calorimeter tests were conducted with full-size sheets of PCM wallboard and showed that small-scale differential scanning calorimeter results could adequately predict results obtained from full-scale testing (Rudd 1993). PCM wallboard may have the potential to shift most of an electric utility’s peak load coming from residential air conditioners to off-peak hours (Neeper 1990). However, in hot and humid climates, thermal storage alone will not provide comfort when implementing air-conditioning load shifting (Kamel et al. 1991). Thermal storage can keep the room’s temperature lower but, with the same absolute amount of moisture in the air, a lower room temperature will make the room’s relative humidity higher. Since environmental comfort is a function of both temperature and humidity (ASHRAE19 89), both thermal and moisture storage must be utilized.

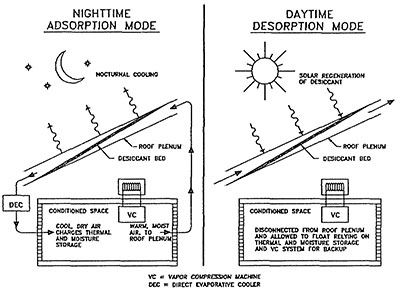

Building-integrated thermal and moisture storage could also make conditions more favorable for the use of advanced solar cooling and heating technologies. One such solar-cooling technology has been under research and development for several years (Swami et al. 1989). Figure 2 shows the basic operating modes of the desiccant-enhanced radiant cooling (DESRAD) concept.

Figure 2: DESRAD operating modes

For the adsorption mode, excess moisture and heat stored by the house during the day are rejected at night to a desiccant bed and the cooler night sky. The desorption mode begins the next day when the sun’s heat is used to regenerate the desiccant bed. The cycle repeats itself every 24 hours, using electrical energy only for fans and an evaporative cooler pump. The system relies on solar regeneration heat, nocturnal cooling, and thermal and moisture energy storage for its operation. PCM wallboard could be used to provide thermal energy storage, while moisture storage could be provided by moisture-storage coatings, yielding a composite thermal and moisture-or enthalpy-storage wallboard.

This paper describes a preliminary research effort toward the development of moisture-storage coatings that could be applied to thermal storage wallboard to achieve enthalpy storage (thermal and moisture storage) in buildings. As moisture is adsorbed in the outer desiccant layer, the PCM layer provides a sink for the heat of adsorption. As moisture is later desorbed from the outer desiccant layer, the wallboard is cooled, removing energy from the PCM so that it may be heated again in the next cycle. This could work well with off-peak cooling since heat and moisture are simultaneously entering the building during on-peak periods and are simultaneously being removed from the building during off-peak cooling periods.

It should be clear that moisture storage alone will not allow air conditioner load shifting. As moisture is sorbed, the heat of sorption must be captured by thermal energy storage in addition to the normal sensible cooling load for any load shifting to be possible.

Test Description

Two moisture-storage coatings were developed and tested in an environmental chamber between late 1990 and early 1991. One coating consisted of grade 11 silica gel desiccant (GR11) mixed with flat latex paint (FLP) as base material. The other coating was made from grade 40 silica gel (GR40) mixed with vinyl joint compound( VJC) as the base material. Approximate loading curves for the two moisture-storage coatings, the base materials alone, and gypsum wallboard (GWB)w ere experimentally determined. The tests were conducted in an environmental chamber. Digital balances were used to monitor the weight change of the samples as a function of relative humidity (RH). The manufacturer of the balances specifies reproducibility at 0.01 g. Table 1 describes the samples that were tested.

Equilibrium moisture-loading curves were measured at 26.7°C (80°F). The environmental chamber was controlled within _+ 1% RH. At each of the 15 equilibrium points, the chamber conditions were held constant until all sample weights were stable within +0.5 grams or +0.4%, whichever was less. All measurements were made every 15 seconds and averaged over six-minute data-logging intervals.

Results

Dry weight was approximated for each sample by curve-fitting the equilibrium sample weights as a function of relative humidity and extrapolating to 0% relative humidity. The moisture content of each sample could then be calculated at each equilibrium point. These data were plotted versus relative humidity. The maximumm oisture content, Umax, was determined from these plots by extrapolating to 100% relative humidity. . .

Download complete document here.