Of course the crazy way we speak about the Second Law does not help: “In an isolated system, a process can occur only if it increases the total entropy of the system.” Huh? It makes you want to hate Rudolf Clausius. Couldn’t he just say that heat goes from warm to cold?1 Most of us get the heat goes from warm to cold thing. It’s the other simple applications of the Second Law that we miss:

moisture goes from warm to cold

moisture goes from more to less2

air goes from a higher pressure to a lower pressure

gravity acts down

The two moisture “rules”—“warm to cold” and “more to less” are nothing more than a “thermal gradient” and a “concentration gradient.” If you combine the thermal gradient and the concentration gradient you get the “thermodynamic potential” and according to the Second Law water always follows the thermodynamic potential. The psychrometric chart is a graphical representation of “warm to cold” and “more to less”—thank you Willis Carrier.

Photograph 1: Space Shuttle—One of the fundamental problems with the Space Shuttle is the shedding of foam from the external tank.

This “warm to cold” and “more to less” thing should be pretty easy. But seemingly smart folks get it wrong all the time. Take the Space Shuttle. The problem with the Space Shuttle is that foam keeps coming off of the external tank of the orbiter (Photograph 1). The problem is best described thusly: we have an aluminum pressure vessel filled with a cryogenic liquid on a beach in Florida in July. The best analogy for this is Photograph 2. The author does not have the research budget of NASA so a few liberties were taken with the authors’ experimental design defining the problem (Photograph 3 and Photograph 4).

Photograph 2: Engineering Analogy—“Aluminum pressure vessel filled with a cryogenic liquid on a beach in Florida in July.”

Photograph 3: Limited Research Budget—“Richard Feynman eat your heart out…you only had a glass of ice water at the Challenger enquiry.”

Photograph 4: Experimental Design—“Authors view of the Space Shuttle foam shedding problem…”

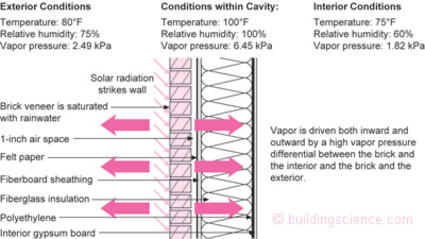

Most of us know intuitively that the Bud will sweat. And most of us know we need to insulate the Bud. But how many of us know that the insulation needs to control the vapor drive? And what is the magnitude of the vapor drive anyway? Figure 1 shows the boundary conditions. The surface of the foam goes to 150 degrees F. on a sunny day—it is brown in color after all. In the summer it rains in Florida every day at 1 pm. So let us add a film of liquid phase water to the surface of the foam and wait for the sun to come back out. Now try to find where the saturation line (i.e. 100 percent RH) crosses the 150 degree F line on a pyschrometric chart. Nope. Not there. Can’t find it. Off the chart, so far off the chart we are in uncharted territory…Try the steam tables. Holy vapor pressure Batman, 13 kPa. Now, how about finding the vapor pressure at minus 420 degrees F? This one is easy—you don’t need no stinkin’ chart for that…can we say “zero’? We are talking some kind of serious inward vapor drive—13 to 0 kpa.

Figure 1: Boundary Conditions—A film of rainwater on the surface of solar heated foam insulation leads to enormous vapor drives.

Now ask the question that certain rocket scientists apparently have not asked: how resistant is the foam insulation on the external tank to vapor flow? The foam has a permeance of 3 perms per inch. The foam is 2 inches thick. Yup, that would make the resistance to flow 1.5 perms. I am no rocket scientist3 but that sounds kind of high permeance wise to me. Seems to me that water vapor will flow through the foam under that magnitude of vapor drive like brown organic matter through a goose.

I wonder what happens when the vapor hits the aluminum lining of the tank? It’s not just foam coming off the tank, but hunks of ice. A way of thinking of this is that we have a vapor barrier on the wrong side of the assembly. Seems to me that we need a vapor barrier on the outside of the assembly. Just for laughs go and “Google” the first shuttle launches and check out the pictures and ask yourself what looks different? Notice the “white” stuff on the external tank of these early launches—looks like a low perm aluminum skin to me. Apparently, the vapor control got “value engineered” out of the assembly after the first few launches to save weight. Violate the Second Law at your peril.

Let’s move on to FEMA and New Orleans and Katrina. It is hard to believe this if you have not seen this with your own eyes. Trailer after trailer after trailer (Photograph 5). Where is New Orleans on the map? It is smack dab in the ASHRAE hot-humid climate region. Most of us intuitively know that this means it is pretty much hot and humid outside almost all the time in New Orleans. Here is the tricky part—we air condition the inside in New Orleans. Yes, it is true. We make the inside colder and drier than the outside in New Orleans. So, work with me on this…the outside is hot and humid and the inside is cold and dry. It is that pesky Second Law again. What direction is the vapor drive? We can actually use a pyschrometric chart for this example and not have to go to the steam tables—so it is not as hard as NASA’s problem.

Photograph 5: FEMA Trailers—Thousands and thousands of these are located in hot-humid climates.

With a dominant inward vapor drive (there is not much of a winter in New Orleans) what is the last thing you would want to see on the inside of an assembly in New Orleans? Yes, that is right, a vapor barrier. You absolutely positively would not ever want to see a vapor barrier on the inside of an air-conditioned assembly in New Orleans. Yes, you guessed it. All FEMA trailers have an interior vapor barrier (Photograph 6). The FEMA trailers are lined with gypsum board wrapped with vinyl facings. And they are turning the trailers into moldy stinky messes. And it is not like FEMA wasn’t warned. They and HUD and the mobile home/manufactured home industry all blindly continue to believe that this is not a problem. But hey, it is poor people in these trailers, who is going to notice?

Photograph 6: Vinyl Covered Gypsum Board—FEMA trailers are lined with vinyl-covered gypsum board as are HUD manufactured houses. This leads to mold problems. The only solution is to not install vinyl covered gypsum board.

But this is America, we can abuse rich people too—especially the ones that stay in Michelin Five Star rated hotels. It is not well known, but in order to get a Michelin Five Star rating a hotel has to have interior vinyl wall coverings. I’m not kidding, this is true. For real. The vinyl wall coverings are associated with “higher quality.” Now for the good part. Vinyl is a vapor barrier. Installing vinyl wall coverings on the inside of air-conditioned hotels in hot humid climates results in mold. See FEMA trailers above.

One of the first signs are “pink spots” on the surface of the vinyl wall coverings (Photograph 7). Molds growing on the back of the vinyl (Photograph 8) exude digestive enzymes that react with the plasticizers in the vinyl leading to the discoloration. These spots are typically referred to as the Marriott measles, the Radisson rash, and the Hyatt hives. Once again the Second Law asserts itself. When I am asked to work on fixing these expensive hotel properties I never stay in them because of the mold, I always stay in La Quinta Inns4 since their “brand look” is “mission style” and has no interior vinyl.

Photograph 7: Vinyl Wall Coverings and Hotels—Marriott measles, the Radisson rash, and the Hyatt hives.

Photograph 8: Hotel Mold—Vinyl wall coverings are low perm materials that retard inward vapor movement and lead

to mold growth.

One of the neat things about the Second Law is that you can magnify the effects with sun and storage and turn what most folks consider a hot humid climate problem into a problem everywhere in the Lower 48 States. Problems with reservoir claddings are making homebuilders forget about sub-prime mortgages. Brick, stucco and fiber-cement siding are all claddings that store water after rain exposure—they act as “reservoirs” that are “charged” during a rain event. It is pretty obvious that reservoir claddings can store a significant amount of water at the exterior of a wall assembly.

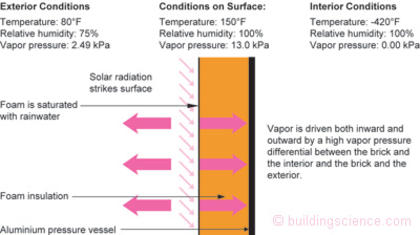

Figure 2: Brick “reservoir” is charged during a rain event and “discharges” both inward and outward magnifying the vapor drives.

Incident solar radiation heats the water stored in the cladding creating a huge vapor drive that is both inward and outward (Figure 2). The vapor drive inward out of a solar heated rain wetted reservoir cladding located in a building in Chicago in July dwarfs by several hundred percent the outward vapor drive in a humidified building located in Barrow, Alaska in January when it is minus 40.5 This leads to summer condensation on the cavity side of polyethylene vapor barriers in places like Chicago (Photograph 9) and Minneapolis (Photograph 10).

Photograph 9: Condensation on Polyethylene Vapor Barriers—Solar driven moisture out of reservoir claddings can lead to cavity side condensation on polyethylene vapor barriers in cold climates such as Chicago.

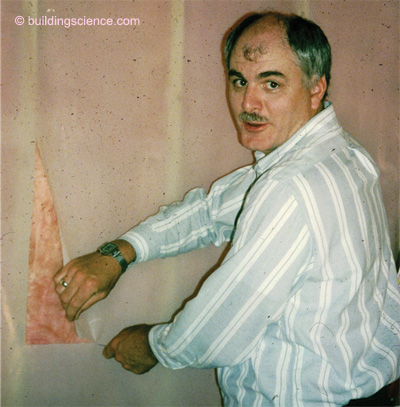

Photograph 10: Minneapolis Misery—Pat Huelman of the University of Minnesota gets a whiff of mold behind a plastic vapor barrier in a Minneapolis house with a plastic vapor barrier.

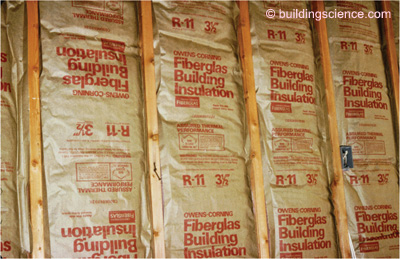

Plastic vapor barriers are a “no-no” on the inside of wall assemblies with reservoir claddings everywhere in the Lower 48 States. Many old timers intuitively knew this and were passionate about using kraft-faced batts rather than polyethylene. Kraft-faced batts act as vapor “retarders” rather than vapor “barriers” in cold climate wall assemblies (Photograph 11). The kraft-faced batts allowed the wall assemblies to dry inwards during the summer especially when the assembly was “stressed” by inward vapor drive out of a reservoir cladding. It appears that mostly the young got “sucked in” to the plastic vapor barrier craze.

Photograph 11: Kraft-Faced Batts—Bless old timers and common sense—the kraft facing breathes during the summer allowing inward drying—polyethylene vapor barriers do not.

If you think about it, if NASA couldn’t get the moisture goes from warm to cold and more to less thing right, then it should not be surprising that FEMA, HUD, the hotel industry and homebuilders couldn’t either. We seem to forget that there are two sides to a wall and that there are several seasons—two of which are summer and winter and that means that vapor drives go both ways. Once again the Second Law strikes.

Footnotes:

Actually he kind of said it—Clausius said “Heat cannot of itself pass from a colder to a hotter body.” I am not really picking on him—Clausius’ work on the Second Law is probably one of the greatest gifts of any one individual to the human race….right up there with Newton and Einstein. But how many people get it? Probably about as many people as get Einstein’s Theory of Relativity. A few more folks do understand Newton—that calculus thing he did is pretty cool. Yes, yes, my German friends, I know about Leibniz, but you already have two of the three folks on my list of important dudes in this footnote…

Thermal diffusion and molecular diffusion are distinct driving forces—so both of these statements are actually true—but separating them is typically not of any practical significance except for reasons that follow. In almost all practical applications in building science “warm to cold” is also in the same direction of “more to less.” It is typically easier to sense or measure temperature so that as a first approximation you can use temperature as your guide to understanding the problem rather than the concentration gradient. Every now and then “more to less” is in the opposite direction as “warm to cold”—under such conditions “more to less” usually wins…rock beats scissors, paper beats rock…more to less usually beats warm to cold.” Once again the “engineer” in me is “approximately correct.” Or just go look at a psychrometric chart—but that is not strictly true either…

Well, not any more—my undergraduate degree was in aerospace engineering—then I got a personality and became a civil engineer.

At this temperature it does not matter whether it is Fahrenheit or Celsius because at minus 40 both scales cross—minus 40 F equals minus 40 C—we refer to that as minus 40 FC for “freaking cold.”