The reason we go to Kentucky for bourbon and not to Pennsylvania is because of the Revolutionary War debt. The new republic started off in a lot of debt because of the Revolutionary War. I know it is hard to believe but war is expensive. How to deal with the debt?

Today, we just print more money (that is how we get inflation) but that hadn’t been figured out yet. In those days, taxes were the only way to deal with debt. What to tax? Old politicians, just like new politicians, like to tax sin.

The fastest way to pay of the Revolutionary War debt was to tax whiskey—or so it was thought. Not everyone was happy about that, especially the folks being taxed. Ever since, avoiding paying taxes on liquor has been a national tradition. It’s how we got bourbon in Kentucky and NASCAR. NASCAR’s roots are in running moonshine1 in fast cars on back roads avoiding the “revenuers.”

The Whiskey Rebellion of 1794 was about taxes and the distillers in Pennsylvania not wanting to pay them. Good old George Washington sent in the army to collect the taxes. The folks making the whiskey “moved lock, stock and barrel”2 out of the Governments reach. They moved out of Pennsylvania to Kentucky. At that time, Kentucky was a rugged, wild place where even the army wouldn’t go. The name bourbon comes from the place a lot of it was first made, Bourbon County, Kentucky.

I have loved bourbon for a long time. I like the history. And I like the independent spirit of the folks who make it, their sense of tradition, and their willingness to continue to experiment. Even now after two hundred years of history, they experiment mostly by trial and error rather than by computer simulations. I have often thought that if engineers were in the liquor business, bourbon would be the liquor they would make.

There is a great deal about making bourbon that I do not understand, but I do know that the barrels are a big deal. The unique flavors of bourbon come from the barrels. Without aging the liquor in a charred oak barrel, all you have is a “clear liquid sprit,” fermented grain that is distilled, or “moonshine.” I am not into moonshine. It makes you want to drive very fast constantly making left turns. It seems to me that the conditions the liquid “sees” in the barrel “makes” the bourbon. The barrel, how the barrel is made and how it is stored, is the key to bourbon.3

Contrary to popular belief the unique shape of oak barrels used for bourbon making has nothing to do with “flavor” and everything to do with mobility. Barrels are easy turn (rotate) around their “bulging middle”4 and are easy to roll on tracks (Photograph 1). Size, that surface area to volume thing, is something else. After 200 years, there is absolutely no size consensus according to the bourbon folks. Some bourbon is made in larger than “standard” sized barrels, some bourbon is made in smaller than “standard” barrels, but most is made in “standard” sized barrel.5

Photograph 1: Bourbon Barrel Railroad – The shape of the barrels allows them to easily roll on parallel rails.

Oak barrels used in the manufacture of bourbon are “charred” to varying degrees in processes that are closely held “secrets” (Photograph 2). The particular type of oak, where it is grown, how old, and what part of the tree the oak comes from are even more closely held “secrets.” The “clear liquid spirit” that is obtained from the distillation of a “secret mixture” of grains in a process called “sour mash fermentation” is stored for varying periods of time under varying and variable conditions in these charred barrels and the result is bourbon. The varying periods of time under varying and variable conditions is where building science comes in.

Photograph 2: Charring of Barrels – Un-charred, medium charred, heavily charred barrels. The charring leads to distinctive flavors as the “clear liquid spirit” changes its color due to the charring to a deep amber color and changes its taste and smell into a uniquely American experience.

Bourbon makers are pretty logical folks. They make stuff, keep track of how they make the stuff, taste the stuff, and if they like it, they make more. They then change things, one at a time, and compare the effect of the changes to the taste of the stuff they like. They also don’t share the information with other folks who make bourbon. Secrets are big in the bourbon business. But you can tell a lot from how bourbon makers store their barrels—and by asking questions such as “what’s with the thermometer in the barrel?” during distillery tours (Photograph 3).

Photograph 3: Barrel Location “Sweet Spot” – In every warehouse there is a location where the resulting bourbon tastes better than bourbon from anywhere else. Clever bourbon makers want to understand why. Measuring the temperature profile of the liquid over daily, weekly, monthly and yearly cycles of the “sweet spot” barrel is helping manufacturers get more “sweet spots” and build more warehouses with bigger sweet spots. How do you know if it is the “sweet spot” barrel? Each barrel is tasted and an “expert” bourbon taster says what is what…. I wonder if they are hiring?

The temperature–time regime of barrel aging apparently is a very, very big deal. In every warehouse there is a location where the resulting bourbon tastes better than bourbon from anywhere else. Clever bourbon makers want to understand why. Measuring the temperature profile of the liquid over daily, weekly, monthly and yearly cycles of the “sweet spot” barrel is helping manufacturers create more “sweet spots” and build warehouses with bigger sweet spots. How do you know if it is the “sweet spot” barrel? Each barrel is tasted and an “expert” bourbon taster says what is what. The goal is to have an entire warehouse of “sweet spots.”

It should come as no surprise that the construction of the warehouse in which barrels are stored has a huge impact on the temperature-time regime. So, what should the temperature-time regime be for good bourbon? I happen to be a “traditionalist” on this matter: not too hot in the summer, not too cold in the winter, with gentle temperature swings between seasons so the bourbon does not get too stressed as it gently ages to perfection. Most people in buildings expect and want varying and variable temperature, depending on outdoor weather, dress and where they were last. Only a computer simulated engineer could think that a fixed, constant uniform temperature and humidity is the most desirable . . . people are like bourbon . . .

You want it to remain above 40 degrees in the winter so that the magic chemical reactions continue to happen during the winter and you want it to stay below 90 degrees in the summer so that the reactions do not progress too quickly. And you need time, many years. Some folks believe two or more decades to get the “really, really good stuff.” Now folks, being folks have figured out that you can “goose” the process by raising the temperatures and increasing the temperature cycles to get you “okay stuff.” What can take decades can be compressed into a couple of years.

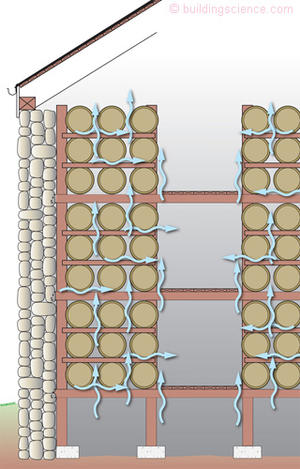

Photograph 4: A Beautiful Sight – Notice that the barrels are stored in a manner that allows air circulation. Warehouses don’t have “floors” in the typical sense. They have “catwalks” between stacks of barrels that are both cross-ventilated and stack (air flow from down low to up high) ventilated.

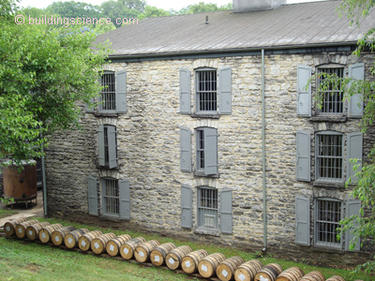

Let’s look at what the “old masters” used to do—to establish a base of comparison. They constructed high mass warehouses coupled to the ground (Photograph 4). Tin roofs were installed over heavy timber decks, supported by thick stone walls. The foundation systems were dirt crawlspaces. The exposed dirt provided humidification in the winter and temperature moderation throughout the year. Cross ventilation and stack ventilation (air flow from down low to up high) further moderated conditions (Photograph 5 and Figure 1). The high mass of the construction and high thermal resistance of the construction (Photograph 6) slowed temperature swings. This resulted in beautiful, but expensive buildings. You can guess the next question: “can we get kind of similar results with less money?”

Photograph 5: High Mass Warehouse – Metal roof over timber deck, stone walls, dirt crawlspace, cross ventilation and stack ventilation. The temperature of the ground and the thermal resistance and thermal mass of the walls moderate the temperature swings within the building. The metal roof is cooler than asphalt shingles or a built up roof.

Figure 1: Older is Better – The exposed dirt provides humidification in the winter and temperature moderation throughout the year. Cross ventilation and stack ventilation (airflow from down low to up high) further moderate conditions. Crawlspaces should be well drained (a crown in the middle with perimeter drains) so that the crawlspace does not reflect only the last rain event.

Photograph 6: High Thermal Resistance and High Mass Wall – Not too shabby for a bunch of Cohee’s—I bet around R-5—with a huge hygric buffer to boot (“hygric buffer” is consultant babble speak for moisture absorption, moisture storage, and moisture desorption).

A lack of money and resources leads to innovation and also to compromises. Low cost uninsulated wood frame buildings clad with metal cladding and metal roofs began to be used for bourbon warehouse aging (Photograph 7).

Typically, the metal cladding and metal roofing was “shiny.” The resulting high solar reflectivity of the wall and roof “knocks” the peaks off the high temperature extremes—rejecting solar radiation in the summer. The low emissivity of the wall and roof “fills” the valleys in the low temperature extremes—reducing radiation heat loss during cold weather. Cross ventilation and stack ventilation further moderate the temperature. Translation, the building does not get as hot as it could in the summer and as cold as it could in the winter. Add a little bit of heat in the winter and you almost, but not quite get an “old” warehouse.

Photograph 7: Low Thermal Resistance/High Reflectivity Warehouse – “Shiny” metal cladding, “shiny” metal roof, open wood frame, no thermal insulation. The thermal control is radiation and ventilation based. High solar reflectivity of the wall and roof “knocks” the peaks off the high temperature extremes—rejecting solar radiation in the summer. Low emissivity of the wall and roof “fills” the valleys in the low temperature extremes – reducing radiation heat loss during cold weather. Cross ventilation and stack ventilation further moderate the temperature. Translation, building does not get as hot as it could in the summer and as cold as it could in the winter.

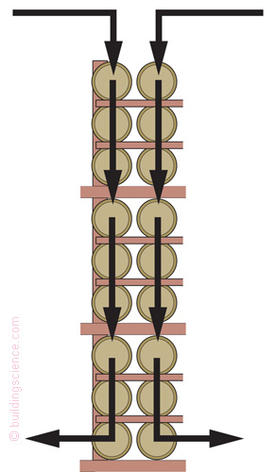

In newer warehouses, you have to get clever with how to store the barrels. In old warehouses you didn’t move the barrels around much if at all. In newer warehouse, because temperature control was not as good, barrels were moved over time (Figure 2). They started up at the top of the warehouse and moved down over time as the aging process progressed and then to market.

Figure 2: Stacking Bourbon Barrels – Because temperature control is not as good in new warehouses, barrels are moved over time. They start at the top of the warehouse and move down as the aging process progresses before going to market.

To “goose” the aging process you can deliberately increase the temperature swings (“amplitude”). This can done by constructing low thermal resistance—low reflectivity warehouses. Warehouses are constructed with open wood frames, no thermal insulation. They are clad with dark (painted) metal sheets and dark (painted) metal roofs. The warehouse is deliberately designed to get hot in the summer and cold in the winter. The roof and wall have high solar absorption gaining heat in the summer. The roof and the wall have high emissivity – increasing radiation heat loss during cold weather. This is the opposite of the approach taken for Low E window glazing—this is a “High E wall and roof.” Now, I have to come clean here, I can’t taste much of a difference between the “goosed” stuff and the “really, really good stuff,” but something about doing it this way bothers me. I guess if you are going to mix it with Coke anyway it probably does not matter, but for the “sippin' stuff” I think it makes a difference.

The wood oak barrels seem to not mind the conditions they are exposed to in either of the two approaches used. Wood is pretty amazing stuff. The barrels made out of it are water tight, water resistant, and vapor resistant. I heard that folks used to make boats out of it that sailed around the world. Over time, even as good as wood is, some outward diffusion of water vapor and alcohol occurs along with inward diffusion of oxygen. Through trial and error the balance of diffusion and chemical reactions and temperature and time lead to a pretty amazing result.

Legend has it that the mold growth on the exterior of old bourbon warehouses is due to the evaporation of alcohol from the barrels and the subsequent diffusion of this alcohol through the walls providing nutrients to support mold growth. The “missing” alcohol from the barrels is called the “angels share.” Of course sometimes mold is just mold (yes, sometimes a cigar is just a cigar…).

Today we tend to use mechanical systems and energy to create specific interior environmental conditions. It is sometimes helpful to go back and look at what was done before mechanical systems and energy consumption ruled the building comfort Universe. Today you just make the HVAC system whatever size you need and buy whatever amount of energy you need in order to create the controlled interior environment you want. The problem with today is that it soon becomes tomorrow and things change—maybe the energy will no longer be available—maybe oil will one day go over $100 a barrel? I am betting that some of those old lessons can be distilled for tomorrow’s buildings.

Photograph 8: Low Thermal Resistance/Low Reflectivity Warehouse – Dark (painted) metal cladding, dark metal roof, open wood frame, no thermal insulation. The warehouse is deliberately designed to get hot in the summer and cold in the winter. The roof and wall have high solar absorption gaining heat in the summer. The roof and the wall have high emissivity—increasing radiation heat loss during cold weather. This is the opposite of the approach taken for Low E window glazing—this is a “High E wall and roof.”

Photograph 9: “Angels Share” – Legend has it that the mold growth on the exterior of old bourbon warehouses is due to the evaporation of alcohol from the barrels and the subsequent diffusion of this alcohol through the walls providing nutrients to support mold growth. The “missing” alcohol from the barrels is called the “angles share.” Of course sometimes mold is just mold (yes, sometimes a cigar is just a cigar…).

Footnotes:

”Moonshine” gets its name because it was typically made at night under the moonlight to avoid being spotted by the tax collectors.

“Lock, stock and barrel” actually refers to muskets—a musket has a flintlock, stock and barrel, but I often use it incorrectly as I did here as a phrase that refers to all of ones possessions—especially the “barrel” reference—because it sounds so cool—call it literary license or just plain making things up…I am a consultant after all…

The corn, water, wheat, rye and malted barley and proportions do matter, but not as much as folks seem to think, in the opinion of this engineer who has absolutely no qualifications to make such a statement.

This sounds like consensus to me since most of it is made this way. Apparently I do not understand the concept of consensus. I think I have been going to ASHRAE meetings for too long. I have been intrigued by small “craft” bourbon makers who are experimenting with barrel size and time of aging. I think size matters, and smaller to me seems better, but most folks aren’t too impressed. Maybe I am starting the conversation incorrectly.