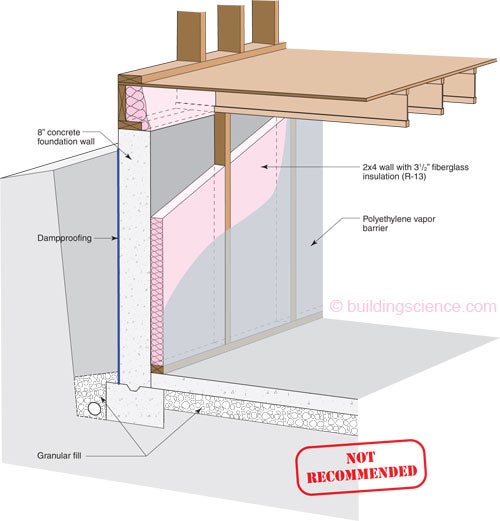

This is another alternative to the minimum code required basement insulation in DOE climate zones 4 and higher. This construction uses a 2x4 framed wall against the concrete foundation with R-13 batts in the stud space. The slab is left uninsulated and the rim joist is insulated using fiberglass insulation.

Foundation Wall

- Free draining backfill

- Dampproofing to grade

- Concrete foundation wall

- 2x4 frame wall with R-13 fiberglass cavity insulation

- 6 mil polyethylene vapor barrier

Foundation Slab

- Uninsulated concrete foundation slab

- 6 mil polyethylene vapor barrier under slab

- 4” stone pad (no fines)

- Undisturbed/ native soil

Thermal Control

This construction technique performs very similarly to High-R Foundation 2. The parallel path method, taking into account the higher conductivity of the framing members at 24” on center results in a R-value inside the concrete wall of R-12.6. This results in a total annual predicted heating energy loss 23.9 MBtus, a savings of 32.8 MBtus.

Moisture Control

This insulation strategy has a very similar poor moisture control level to High-R Foundation 2. Moisture is constantly moving from the below grade exterior portion of the foundation wall to the interior, and becoming trapped in the framed wall cavity. The relative humidity is elevated and condensation is almost guaranteed both on the concrete wall and on the polyethylene vapor barrier throughout the year (Figure 2). If there is air leakage (or the facer is air permeable) there is condensation potential on the concrete foundation through most of the year as shown in Figure 3. Because these simulations are one dimensional, they are good approximations, but heat flow in the foundation wall is three dimensional. Also, in the air permeable insulation, convective looping is likely, which may increase the condensation above predicted results. Field investigations show that it is quite common to get high quantities of mould in this wall system.

Figure 2: Predicted RH at the interior surface of the concrete foundation wall

Figure 3: Condensation potential for interior air on the surface of the concrete foundation wall

Constructability and Cost

This wall is slightly more expensive than High-R Foundation 2 because of the framing lumber required but does have the added benefit of being able to finish it easier by adding services and drywall easier.

Other Considerations

This wall construction technique is not recommended, because of the obvious moisture related durability issues observed in the field, and shown by simulations. The wood framing in this wall is at risk of mold and rot after prolonged exposure to the conditions predicted in the wall system.

Reference

Mitalas, G.P., Calculation of Basement Heat Loss, National Research Council Canada.