This digest will begin with a brief description of the system and materials, review moisture problems in buildings, and summarize how moisture control should be dealt with in strawbale buildings.

The System

The classic and time-proven strawbale wall assembly consists of strawbales laid flat with a 1 to 1.5 inches (25 to 38 mm) thick metal mesh reinforced cement and/or lime stucco skin applied directly to each face. Earth plasters, usually somewhat thicker, have also been widely used. It behaves in most respects like a sandwich panel system, e.g., Structural Insulated Panel Systems (skins of OSB glued to foam plastic cores), reinforced cement skins glued to a polystyrene core, etc.

The reinforced skins take almost all of the load since these are the stiffest and strongest materials in the system. The strawbales act as a substrate for the stucco and as effective insulation.

Photographs 1 and 2: Strawbale walls can be built with locally available materials and community labor (left) and are often chosen for their sculpted, massive aesthetics (right).

The Materials

The primary constituents of the classic strawbale wall system are stucco and strawbales. The properties of each are examined below.

Properties of Stucco

The stucco used in strawbale walls can range from high-strength gunite or shotcrete to earth-based plasters. In most buildings the better understood cement-based stuccos are used, although lime and earth plasters will tend to have better drying performance. Typical mixes are 1 part cement to 3 parts sand and 1 part cement, 0.5 parts lime and 4.5 parts sand. Although the straw to stucco bond is very strong, and straw tends to act as a reinforcement for the applied stucco, metal mesh is often added to provide structural ductility to the skins. The mesh should be galvanized to protect it from corrosion as required by most codes.

Mesh reinforced cement-lime based stucco will typically have compressive strengths of 15 to 35 MPa (2000 to 5000 psi) and equivalent tensile strengths of 0.2 to 0.7 MPa (20 to 100 psi), depending on the quality and quantity of wire mesh reinforcing. The stiffness of such stucco is in the range of 10 000 to 25 000 MPa (1.4 to 3.6 x 106 psi).

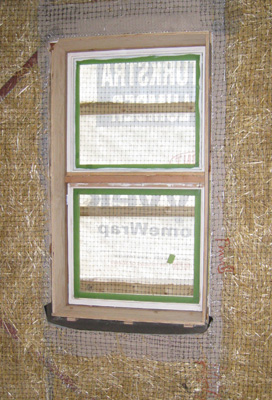

Photograph 3: Window framing (with subsill flashing), shear bracing and wire mesh reinforcement. This wall is ready for plaster.

The vapour permeance for 25 mm (one inch) thick cement-based stucco tends to lie in the range of 200 to 500 metric perms (ng/Pa s m2) or 4 to 9 US perms. The addition of lime tends to increase the vapour permeance to the range of 400 to about 800 perms or 7 to 14 US perms. Pure lime and earth stuccos have an even higher vapour permeance, of as much as 1000 perms (18 US perms).

Properties of Strawbales

Straw is defined as the dead stalks of small grain-bearing cereals. In this part of the world, wheat, barley and oat straw are the most commonly available. Bales are formed by compressing and tying strings around packages of straw. There are two common sizes of bales, 18” wide and 14” high or 24” wide and 16 to 18” high. The length is somewhat variable and adjustable, although the length is generally in the range of 32 to 40". Strawbales can have a wide range of densities. Most strawbale codes in the US have chosen to use a minimum density of 7 pounds per cubic foot, (110 kg/m3) since it is generally agreed that higher density bales are superior (e.g., bales up to 12 pcf are available).

Several tests of the properties of the strawbales themselves have been conducted. In many respects, strawbales behave like cellulose insulation, sawdust, or wood shavings, cellulose-based materials with which we have many years of widespread experience in cold, warm, and mixed climates. The advantage of straw is the tubular shape of its stalk. This creates more void ratio for the same density of cellulose material and provides good R-value as well as reduced capillary suction, e.g., strawbales do not “wick” water very effectively. The very limited capillary suction of straw means that a separate capillary break in the form of building paper is not strictly necessary (water will definitely not wick from the exterior stucco to the interior!).

Water vapour is stored in strawbales in the same way as wood or cellulose insulation, e.g., in the winter the equilibrium moisture content will be about 8-12% moisture content by dry weight, and the moisture content can rise to at least 20% before moisture problems begin. Hence, for a 8 pcf bale, more than 1 pound of water in vapour form can safely be stored per square foot of wall area.

Testing for R-value has been conducted several times. Only a few tests of full-scale walls (rather than bales) have been conducted (by Oak Ridge National Labs and the Technical University, TUNS, of Nova Scotia). The R-value for these walls were found to be between 26 and 30, about double that which can be expected from a wall built to most code requirements. (Note that a 2x6 wood frame wall with R-20 batts has an R-value of about R-13 when the thermal bridging through the studs is considered). Strawbales are comprised of over 90% air voids, easily connected to one another. Hence, they acts as highly vapour permeable insulation (about half the vapour permeance of batt insulation), with a permeance in the order of 200 to 400 metric perms (3 to 6 imperial perms) for a 450 mm (18”) thick wall. Strawbales are also quite air permeable, although much less than batt insulation, provided that the bales are sufficiently dense. They cannot be relied upon to control airflow without the addition of a supplementary air barrier system (such as stucco).

The stiffness (E-modulus) of strawbales have been found to be between about 0.1 and 0.2 MPa (15 to 30 psi), depending on density. The bales did not fail or crush in tests which subjected them to over 25% compression, but the useful level of stress was approximately 0.01 to 0.02 MPa (1.5 to 3 psi). These values are based on tests conducted by TUNS on oat, barley, and wheat bales from various suppliers, with a density of 55 kg/m3 (3.4 pcf) to 115 kg/m3 (7 pcf). Higher density bales are stiffer.

Tests by the author have shown that the bond of stucco to straw is in the order of 0.07 to 0.15 MPa (10 to 20 psi). As supplemental attachment, wire ties in each course of bales can be used to tire the two wire meshes, and hence the stucco, together. This detail is normally only used in earthquake prone areas like New Zealand and California.

The stiffness of stucco is much higher (at least several thousand times!) than that of the straw bales, and the area only about 1/9 as much (e.g., two one inch skins over an 18” bale). The stiffness ensures that the skins take 95-99% of all vertical load applied. Walls which are plastered with the softer earth plasters usually use thicker plasters (2 or 3”) and hence the same proportion of the load is usually taken by these skins. Therefore, a strawbale wall system is truly a sandwich panel, and the strawbale core acts predominately as insulation and a core. The bond strength of the stucco to the straw and the compressive resistance of the straw act to prevent buckling or delamination of the skins.

Durability and Performance: Moisture

Moisture is one of the most important factors affecting building enclosure durability and performance. Moisture is required for most common performance problems, such as rot, dissolution, staining, mould growth (IAQ), corrosion, freeze-thaw damage, cracking and swelling. In the case of a strawbale building the potential moisture-related concerns are mould growth, rot of the wood components, and corrosion of steel. These are the same types of problems that must be avoided in normal wood frame walls.

Different materials have different moisture performance thresholds. Corrosion of steel occurs as a function of its time of wetness (how many hours per year is it damp) the salt content of the vapour (e.g. from the ocean or deicing salts), the acid content of the vapour (from industry) and the temperature (the warmer the faster corrosion occurs). Corrosion begins at a surface relative humidity of over 80%RH. Mould growth on wood and straw can occur when either is exposed to prolonged periods over 80%RH (about 20% moisture content). Wood rots if exposed to liquid water or over 95%RH for several months at warm temperatures. We know that wood will not rot below about 28 to 30% moisture content. It is believed that straw will rot at a slightly lower moisture content because of its much higher surface area.

For a moisture-related problem to occur, at least four conditions must be satisfied:

a moisture source must be available,

there must be a route or means for this moisture to travel,

there must be some driving force to cause moisture movement, and

the materials and/or assembly must be susceptible to moisture damage.

To avoid a moisture problem one could, in theory, choose to eliminate any one of the four conditions listed above. In reality, it is practically and/or economically impossible to remove all moisture sources, to build walls without imperfection, to remove all forces causing moisture movement, or to only use materials which are never susceptible to moisture damage. Therefore, controlling moisture and reducing the risk of failure by judicious design, assembly and material choices must be the approach taken in the design of durable building enclosures.

The Moisture Balance

If a balance between wetting and drying is maintained, moisture will not accumulate over time, and moisture-related problems are unlikely. A review of the major sources and sinks of moisture and the transport mechanisms typically involved in moisture movement in walls, especially strawbale walls, is provided below.

Wetting

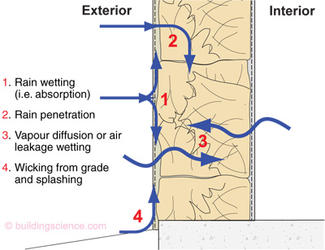

The three major sources of moisture for the above-grade building enclosure are:

condensation of water vapour transported by diffusion and/or air movement through the wall (from either the interior or exterior),

precipitation, especially driving rain, both by penetration and capillary absorption,

built-in and stored moisture.

(Enclosures at or below grade also need to deal with moisture from ground sources such as surface run off, melt water, high water tables, etc.)

Driving rain is usually the largest moisture source for above-grade walls. Rain deposition on one or more faces of an exposed building in many parts of North America has been measured to be in the order of 200 kg/m2/yr. The addition of an overhang, pitched roof, and protection from neighbouring buildings can reduce this exposure by a factor of 10. The majority of any rain deposited tends to be shed by stucco, with a significant amount absorbed while a small amount penetrates through cracks. The majority of water penetration problems with stucco occurs at penetrations. Driving rain control is dealt with in a subsequent section.

Condensation of the water vapour in exfiltrating air during cold weather or infiltrating air during hot-humid conditions can also deposit significant amounts of water within a wall. While diffusion wetting is typically not a powerful wetting mechanism, diffusion is an important means of moisture movement between the stucco layers and straw in a strawbale wall.

Built-in moisture can be important in some wall assemblies. The use of wet framing lumber, saturated concrete block, or green concrete within a wall may provide a large initial source of moisture. The built-in moisture from concrete foundations and stucco must be allowed to dry out. Thus, SB walls should be designed to allows drying by choosing properly vapour permeable materials. The major source of built-in moisture, the stucco skins, can dry very quickly because of their location.

Wicking and splashing from the ground can be a problem for walls close to grade. Both can be controlled by flashing, well-drained soils, good eavestrough and site drainage, etc. The stucco-coated strawbale must be kept at least 6” (150 mm) above grade, although 8-12” (200-300 mm) is recommended.

Figure 1: Wetting mechanisms in strawbale walls

Moisture control strategies for many modern walls have tended to focus on reducing the potential for wetting by, for example, increasing air tightness and interior vapour resistance, reducing the volume of water penetration and absorption, etc. However, it has become generally accepted that most building construction will not be perfect, and thus wetting will occur. Therefore, attention must be given to design approaches that increase a wall's drying and/or storage potential.

Drying

An assembly's drying potential is an important factor in assessing its vulnerability to moisture problems. Strawbale walls, like solid multi-wythe brick walls, adobe and straw-clay walls, are more susceptible to wetting than a modern wood frame wall. But as history has shown, these types of walls can be quite durable so long as drying is allowed.

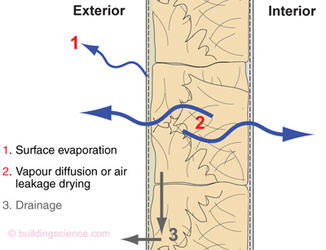

Moisture is usually removed from a wall by:

- evaporation from the inside or outside surfaces,

- drainage, driven by gravity,

- vapour transport by diffusion either outward or inward or both; and

- air flow either outward or inward or both.

Drainage is the mechanism capable of removing the greatest volume of water in the shortest period of time. Hence it is can be a very important mechanism for moisture control. Provided a clear drainage path exists (e.g. cavities, slopes, drainage openings), a large proportion of rain water penetration or condensation can flow out of certain walls, such as brick veneer, vinyl, etc. However, drainage is not the only mechanism or even sufficient on its own, to provide drying. Stucco clad walls, solid masonry walls, and strawbale walls can function well by using other drying mechanisms, and attempting to incorporate drainage in these time-proven designs often creates an inferior wall system.

Drainage within strawbale walls is not a reliable rain control strategy as the straw becomes too wet during the drainage process. Drainage of windows, doors, and any penetrations IS effective and should always be incorporated into a strawbale wall.

Figure 2: Drying mechanisms in strawbale walls

Under the right conditions the moisture from rain penetration and condensation not drained from a wall will dry by evaporation or desorption. The resulting water vapour can be transported out of and redistributed within a wall system either by diffusion or air leakage or both acting together.

Diffusive drying is one of the two mechanisms that can remove moisture that is absorbed or trapped in a wall. Diffusion outward, especially when driven by large vapour gradients in the winter, can remove a significant amount of moisture and be an effective drying mechanism. Outward drying for strawbale walls can occur in most parts of Canada since exterior stucco has a relatively high vapour permeance and the outdoor vapour pressure is often quite low in winter. Diffusion drying can only occur in an outward direction if very low permeance polyethylene vapour barriers are located on the exterior side of the interior finish. In walls exposed to solar heating, inward drying can be significant if it is allowed by the use of relatively vapour permeable interior layers. For example, a significant proportion of drying can occur to the inside in strawbale walls, so long as polyethylene or similar vapour resistant layers are not used.

Air flow (or leakage) through the enclosure can, under the proper conditions, move a large quantity of moisture. While air leakage usually leads to condensation wetting under many winter conditions, it can also remove moisture during warmer weather. Periodic reversals of air flow from exfiltration to infiltration (when the wind changes direction for example) can allow drying even under winter conditions. Similarly, cold weather stack-effect-driven infiltration and warm weather exfiltration can cause drying. Since the amount of air leakage drying and wetting cannot easily be predicted or controlled the recommended approach is to control all air movement and secure drying by other mechanisms.

Capillary transport, often termed wicking, is not itself a drying mechanism but it does act to redistribute moisture within a system. Stucco is highly capillary active and wicks water quite effectively. This means that water that is deposited on one face of the stucco can be transported to the other. In practice, water that penetrates stucco (from any source) will evaporate, diffuse to the back of the stucco and either pass through to the exterior or condense on the back face. Any vapour that condenses will wick to the exterior surface from where it can quickly evaporate. This drying mechanism is one reason not to introduce building paper between the stucco and straw.

Drying almost never occurs at the same time as wetting. Therefore, to bridge the gap in time between wetting and drying, some safe storage capacity within the wall is needed.

Storage

The ability of a wall assembly to store moisture may be an important measure of its durability because storage acts as a vital buffer, or capacitor, between the deposition and removal of moisture. However, if the volume of stored water exceeds the safe level for a material and is present for long enough, deterioration can occur, i.e. rot of wood and straw, freeze-thaw damage of masonry, and corrosion of metal. Therefore, the two most important characteristics of moisture storage are: how much moisture can be stored and for what duration without crossing a performance threshold.

Sorption of water vapour by hygroscopic materials is an important storage mechanism. A significant amount of moisture can be stored within a porous material as water vapour molecules adsorb to the large internal surface areas of materials such as straw, wood, concrete and masonry. When a porous material has adsorbed all the moisture it can, further moisture will be stored in the pores and cracks within the material by capillary suction, or by absorption. Only when all pores are filled with water is a material saturated. For example, wood will adsorb moisture up to approximately 30% of its mass in the adsorbed state and fully saturated wood can hold two to four times this amount of water. When all easily filled pores of a material are filled with water, the material is capillary saturated. A capillary saturated material will generally not be able to store any more moisture. Water stored in pores generally must leave in vapour form.

Safe storage capacity depends on the material. Wood and straw can generally store about 20% moisture by weight without danger of mold growth. Steel cannot store any water safely—hence, any water in the studspace can immediately act to corrode the steel. The ability to safely store significant amounts of moisture means that the drying period can occur a long time after wetting, perhaps several months. This improves the chance of a moisture balance being struck.

Rain Penetration Control for Strawbale Buildings

Precipitation, often the largest source of moisture in buildings, is always a concern for strawbale buildings. Designers have a choice of three primary rain control strategies in all enclosure systems. Enclosure elements and the joints between these elements may be, and often should be, designed with different strategies.

Perfect barrier systems employ a single layer through which no rain may penetrate. If this perfect layer is on the exterior, the wall can be sub-classified as a face-sealed system.

Mass or storage walls control rain penetration by absorbing and storing rain water which penetrates the exterior surface. In a functional mass wall this moisture is eventually removed by evaporative diffusive drying before the accumulated moisture causes damage.

The screened and drained design philosophy accepts that water penetration will occur and provides drainage at several planes to remove it. A rainscreen, pressure-equalised rainscreen, and two-stage weather tightening are all sub-classifications of the screened and drained enclosure type.

Providing a water-resistant barrier (drainage plane) behind the stucco is not practical in strawbale construction because it breaks the structural bond between the plaster and the strawbale and reduces the ability of a wall to dry outward. Hence, rain control in strawbale walls employs the mass/storage approach. The ability of a wall to store and dry rain water deposited on the surface is very important for mass wall systems, no less for stawbale systems. The mass and absorption provided in every mass system must be balanced with the drying capacity and the exposure to driving rain. For example, split-faced concrete block is a highly absorptive, but highly massive wall system. Provided such walls are not exposed to too much rain, they will not leak and they will dry out. It is for these same reasons that good drying capacity and reduced driving rain exposure are so important to strawbale walls. Stucco is less massive, but less absorptive than split-faced block.

Research and long experience has shown that overhangs are very effective in reducing the amount of rain deposition. Buildings, trees and terrain around a house can also provide significant protection. Finally, the closer to the ground a building is, the less driving rain deposition that occurs. Driving rain deposition can be reduced to such a level by even one or two of these measures acting alone that even the storage mass of the 25 mm stucco skin can store the rain that penetrates and is absorbed. All strawbale houses should control rain exposure through the use of generous overhangs, eavestroughs, and by keeping walls to two-storeys or less in height. The size of the overhang will depend on exposure and building shape, but a minimum of 400 mm (16”) for a one storey building and 600 mm (24”) for a two-storey building is recommended by this author.

Experience with strawbale and other stucco houses has shown that rain penetration almost always occurs at penetrations though the wall. Therefore, windows, doors, balconies and other large penetrations need to be detailed with more than average care to eliminate the potential for rain penetration. As a minimum, detailed sections of window and door sills, jambs and heads should be provided to the building code official to demonstrate that care has been taken in the design of these features. Clearly it is in these areas that waterproof membranes and flashings should be used.

For strawbale walls exposed to high rain exposures (tall houses with little overhangs) a drained system is recommended: on the exterior of a typical plastered strawbale assembly, a small drainage gap and an external finish can be provided. This drainage gap need only be 1/16” or even less and can be formed by special creped housewrap, or strips of wood. The exterior finish can be a plaster, siding, wood, or any other lightweight system.

Air Leakage Condensation Control for Strawbale Buildings

The second largest potential source of wetting for strawbale walls is condensation of the water vapor in the air. This moisture can be transported by diffusion (the movement of something from high concentration to low, such as the smell of an onion from one end of a room to the other without air movement) or air movement itself (the movement of the onion odor from one room to another by moving the air itself, with a fan or by wind, etc).

Vapour diffusion is not a concern for strawbale homes because the interior plaster is able to resist a sufficient amount of vapour diffusion to control diffusion. Air leakage however might be a concern, and an effective air barrier system must be provided.

It should be noted that condensation will occur on any surface which is colder than the dewpoint of the air around it. In practice, condensation does not occur within batt insulation or strawbales, since neither presents a sufficiently attractive surface (they are mostly composed of air and are very vapour permeable). Condensation in framed walls and strawbale walls tends to concentrate on the first surface on the cold side of the dewpoint.

The condensation surface in cold weather is usually the back of the sheathing in framed walls, or the back of the stucco in a strawbale wall. Any moisture that condenses here must dry to the outside. This occurs in sheathed walls by drying directly to the outside via ventilation of the cladding. In strawbale walls, condensate will be wicked into the plaster, and will subsequently evaporate from the exterior surface. This is an efficient drying mechanism. Placing building paper between the stucco and the straw will eliminate this condensation-wicking-drying mechanism and force any water to evaporate through the building paper and the full thickness of the stucco.

The air barrier provided by applied reinforced stucco is excellent, better than most other systems. Laboratory tests have confirmed that the small cracks that typify a stucco finish are not big enough or continuous enough to allow significant airflow. Just as for rain, the majority of air leakage will be at penetrations and interfaces with different wall surfaces. It is recommended that the interior and exterior skins be detailed as part of the air barrier system. This can be accomplished by caulking to hard surfaces (interior caulk has a long lifespan) and by applying one-component polyurethane foam or peel and stick membrane to the more difficult, convoluted or rough surfaces. Project drawings should specifically identify the air barrier system and indicate how continuity of the system is to be achieved (from the floor slab to the roof via the walls and windows).

Summary

In summary there are no real technical obstacles to the use of strawbales in a manner that meets the intent of all building codes. The practical experience with thousands of such buildings provides more than sufficient confidence in the conclusions of this technical review.

Practical moisture-related concerns such as the need for air, vapour, and rain control can be met. This is not to say that all strawbale buildings are necessarily durable and performing—good performance and durability depends very much on the construction details used and the exposure of the site. Rain control is the most important issue, and an air barrier system must always be provided in cold or hot-humid climates. Vapour diffusion control can easily be provided in cold climate walls: in a standard cement-stucco strawbale house wall by interior painted stucco (with a permeance of no more than about 300 metric perms).

Proper rain control means deflecting as much rain as possible through the proper use of overhangs, eavestroughs, base details, protected sites, etc. Large-scale details of all penetrations, showing how rain and air flow will be controlled, especially at windows and balconies, must be developed for each project and each wall arrangement. Such details should ideally be part of the project drawings submitted for building permit approval.

Photographs 4 and 5: Generous roof overhangs provide shading and shelter for these strawbale buildings

The use of sheet barriers to liquid and vapour movement is always a double-edged sword—the barrier that prevents wetting also slows drying. These types of barriers are likely to cause the very problems they are intended to solve in strawbale construction and should be avoided. Both practical experience and building science provides ample evidence to support this approach.

Reference

The definitive handbook of technical strawbale design is "Design of Strawbale Buildings" edited by Bruce King, PE, available from Green Building Press.