Forced air distribution ducts are often hard to seal. Air leakage in ducts makes it difficult to assure that the correct quantity of air is conveyed to or from the intended space. In order to reduce duct leakage and the overall cost of installing sealed ducts, central return ducts are preferable to distributed return ducts. Our cold-climate design calls for a central return on each conditioned floor, and a separate return for the master bedroom. In order to assure that the intended amount of supply air is delivered to each secondary room without over-pressurizing the room (< 3 Pa), air transfer grilles are specified. Transfer grilles represent a cost-effective alternative to individual return ducts if they are properly configured for air flow, privacy, and aesthetics.

Background

The Building Science Consortium of the US DOE Building America Program seeks to construct energy efficient, durable, and healthy homes that consume 30% less energy than conventional homes built to local codes. Improvements to the mechanical heating, cooling, and ventilation system are part of the overall engineered package. The comfort conditioning delivery system used is generally forced air. Forced air distribution ducts are often hard to seal. Air leakage in ducts makes it difficult to assure that the correct quantity of air is conveyed to or from the intended space.

In order to reduce duct leakage and the overall cost of installing sealed ducts, central return ducts are preferable to distributed return ducts. Our cold-climate design calls for a central return on each conditioned floor, and a separate return for the master bedroom. In order to assure that the intended amount of supply air is delivered to each secondary room without over-pressurizing the room ( 3 Pa), air transfer grilles are specified.

Transfer grille configurations

Transfer grilles can be installed in several ways to address the combined requirements of air flow, privacy, and aesthetics. Figure 1 shows how transfer grilles can be installed high and low on opposite sides of a sealed wall cavity. Installing one grille high on the wall facing the central area, and one grille low on the wall facing the closed room, allows return air to flow without compromising auditory or visual privacy.

Where the high/low configuration is not possible, transfer grilles can be installed over doors in non-bearing walls. Installing one grille to the right and one grille to the left horizontally separates the grilles, eliminating any visual privacy problem and reducing sound transfer.

Where ceiling transfer grilles are preferred, and when ducts will remain inside conditioned space, a short duct, commonly called a "jump duct," can be installed to connect a ceiling transfer grille in the secondary room to a ceiling transfer grille in the central area. This is shown in Figure 2.

In all cases, it is important that the grille be mounted such that the blades of the grille are oriented to reduce visual impact, so that the interior of the wall cavity cannot be seen. For instance, for grilles installed above eye level, the blades should angle down, away from the viewer. For grilles installed below eye level, the blades should angle upward away from the viewer. Grilles with longer curved blades and a one-way air flow pattern are preferable to those with short straight

blades. See the brief list at the end of some suitable grilles.

Transfer Grille Sizing Calculations

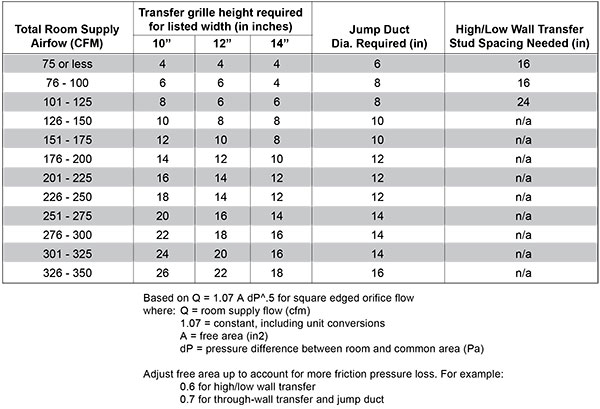

Table 1 shows the sizing specifications for using 10”, 12” or 14" wide transfer grilles with 70% free area as a function of room supply air flow. The transfer grille sizing includes allowance for one 32" by 1/2" door undercut.

Typical Free Area Measurements of Return

Table 2: Ameri-Flow Air Grilles; data from Grainger Catalog (2001)

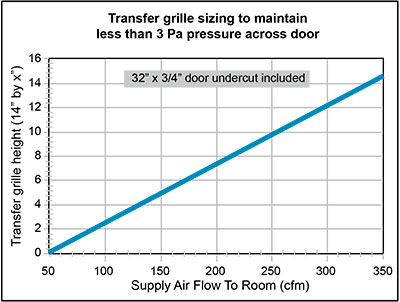

Figure 1: Transfer grille sizing for 14" wide grille with 80% free area, with 32" x 3/4" included

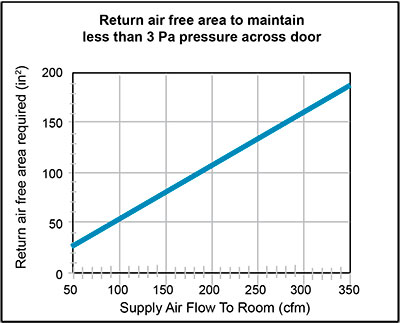

Figure 2: Return air free area required to maintain less than 3 Pa pressure difference across door

Brief list of some grilles/registers that can work well as transfer grilles

Hart & Cooley

A600 Series Register (residential product)

Aluminum construction.

Adjustable curved blades increase deflection control.

One, two, three and four-way air patterns.

Multi-shutter valve.

For sidewall or ceiling application.

Equipped with gasket.

Bright White enamel finish.

Sizes from 4" x 8" (100mm x 200mm) to 8" x 14" (200mm x 350mm).

Tuttle & Bailey

A40/A20 Curved Blade Ceiling Grilles & Registers (commercial product)

Extruded Aluminum construction.

Adjustable curved vanes in 1, 2, 3, and 4-way patterns.

Available with opposed blade damper.

1 -1/4" (30mm) nominal margin with gasket.

Sizes 6" x 4" (150mm x 100mm) to 72" x 36" (1830mm x 910mm) in one piece

Satin Anodized or Baked White enamel finish.

Hart & Cooley

657 Baseboard Return Air Grille

All steel construction.

1/3" (10mm) spaced fins set at 20.

7/8" (20mm) margin turnback.

Exceptional free area.

Bright White or Golden Sand enamel finish.

Available in sizes 8" x 6" (200mm x 150mm) to 36" x 12" (910mm x 300mm).

Hart & Cooley

650/672 Return Grille

All steel construction.

1/3" (8mm) or 1/2" (10mm) fin spacing.

In sizes 15-3/4" x 7-3/4" and 31-1/4" x 7-3/4"(395mm x 195mm and 780mm x 195mm).

Standard finish Bright White.

Heavy-gauge, multi-angled fins reduce resistance and allow for optimum air distribution. . .

Download complete report here.